Hasung - 20KG Lub Tshuab Nqus Tsev Granulating Tshuab Foundry Hlau Casting Tooj Liab Nyiaj Kub

Hasung - Nqus Granulating Tshuab Foundry Hlau Casting Copper Silver Gold Granulation Tshuab piv nrog cov khoom zoo sib xws ntawm lub khw, nws muaj qhov zoo sib xws ntawm kev ua tau zoo, zoo, zoo li, thiab lwm yam., thiab nyiam lub koob npe nrov hauv kev ua lag luam.Hasung piav qhia txog qhov tsis xws ntawm cov khoom dhau los, thiab txuas ntxiv txhim kho lawv. Cov specifications ntawm Hasung - 10KG High Vacuum Granulating Tshuab Foundry Hlau Casting Copper Silver Gold Granulation Tshuab tuaj yeem kho raws li koj xav tau.

Hauv peb lub tuam txhab, peb tau hloov kho peb cov thev naus laus zis los tsim cov khoom lag luam. Nrog rau cov khoom no, Hasung 50KG Nqus Granulating tshuab Foundry Hlau Casting Copper Silver Gold Granulation Tshuab tau ua haujlwm zoo heev hauv daim ntawv thov teb ntawm Hlau Casting Machinery.

Kev piav qhia

Siv lub teb chaws Yelemees IGBT induction cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv thev naus laus zis, nws tuaj yeem yaj hauv lub sijhawm luv luv, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, thiab kev ua haujlwm siab.

2. Cov hom kaw + lub tshuab nqus tsev / inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab tiv thaiv kev sib xyaw ntawm impurities. Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim.

3. Siv lub kaw lus + lub tshuab nqus tsev / inert roj tiv thaiv melting chamber, melting thiab nqus tsev yog ua nyob rau tib lub sij hawm, lub sij hawm yog halved, thiab ntau lawm efficiency yog heev txhim khu kev qha.

4. Melting nyob rau hauv ib tug inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon crucible yuav luag negligible.

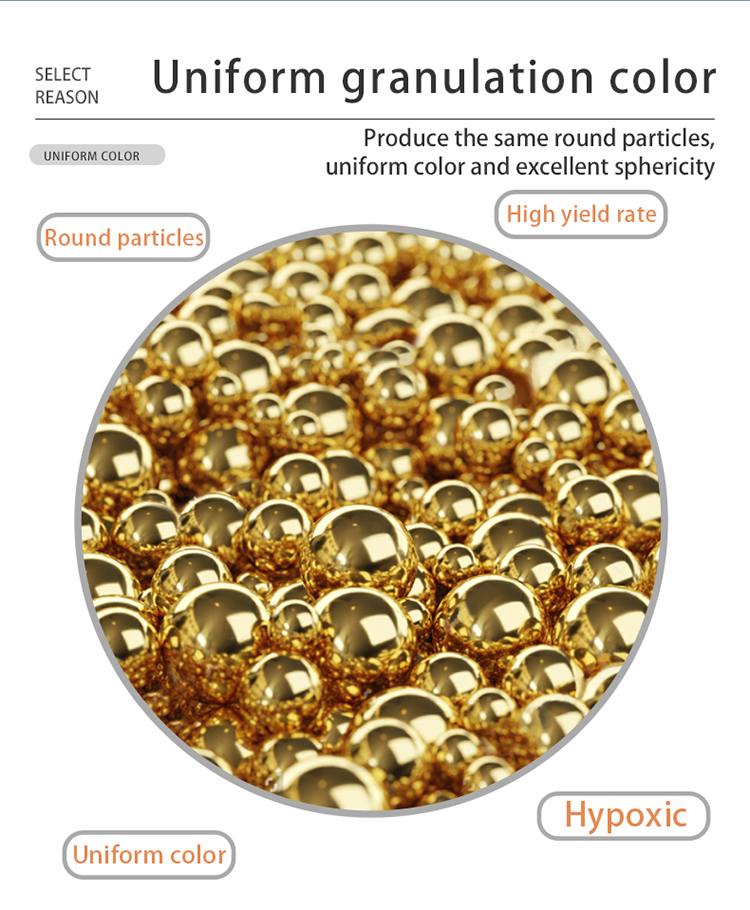

5. Nrog rau electromagnetic stirring muaj nuj nqi nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim. 6. Nws txais qhov yuam kev pov thawj (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim rau kev siv.

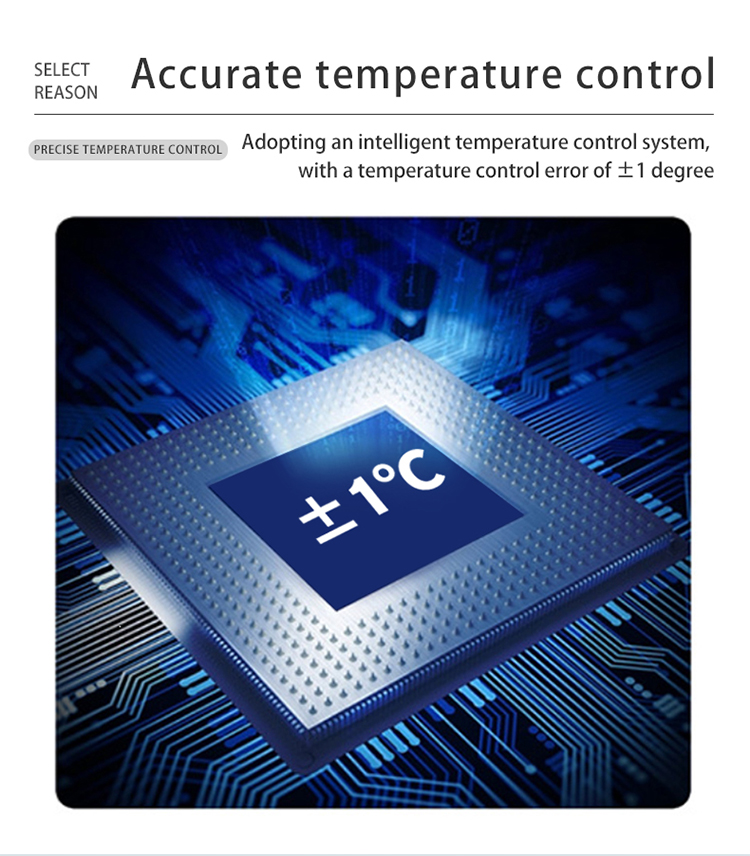

7. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C). HS-GR lub tshuab nqus tsev casting cov cuab yeej yog tsim los ntawm nws tus kheej thiab tsim nrog cov cuab yeej siv siab heev thiab muaj nplooj siab rau melting thiab casting kub, nyiaj, tooj liab.

9. Cov khoom siv no siv Nyiv SMC pneumatic, IDEC, Shimaden, Lub teb chaws Yelemees Omron, Siemens, thiab lwm yam khoom lag luam muaj npe nrov hauv tsev thiab txawv teb chaws.

10. Melting, electromagnetic stirring, thiab tub yees nyob rau hauv ib tug kaw + lub tshuab nqus tsev / inert gas tiv thaiv melting chav tsev, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj pores, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

Cov ntaub ntawv technical

Qauv No. | HS-VGR 20 | HS-VGR30 | HS-VGR50 | HS-VGR100 |

Qhov hluav taws xob | 220V, 50/60Hz | 220V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

Fais fab mov | 0-30KW | 0-30KW | 0-30KW | 0-50KW |

Max Temp | 1500°C | |||

Lub sij hawm yaj | 8-10 feeb. | 8-15 feeb. | 10-15 feeb. | 20-25 feeb. |

Tiv thaiv Gas | Argon / Nitrogen | |||

Temp raug | ±1°C | |||

Peev xwm (kub) | 20kg ua | 30kg ua | 50kg ua | 100 kg |

Daim ntawv thov | Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys | |||

Lub tshuab nqus tsev | Lub tshuab nqus tsev siab qib German Lub tshuab nqus tsev twj tso kua mis, Nqus degree-100KPA | |||

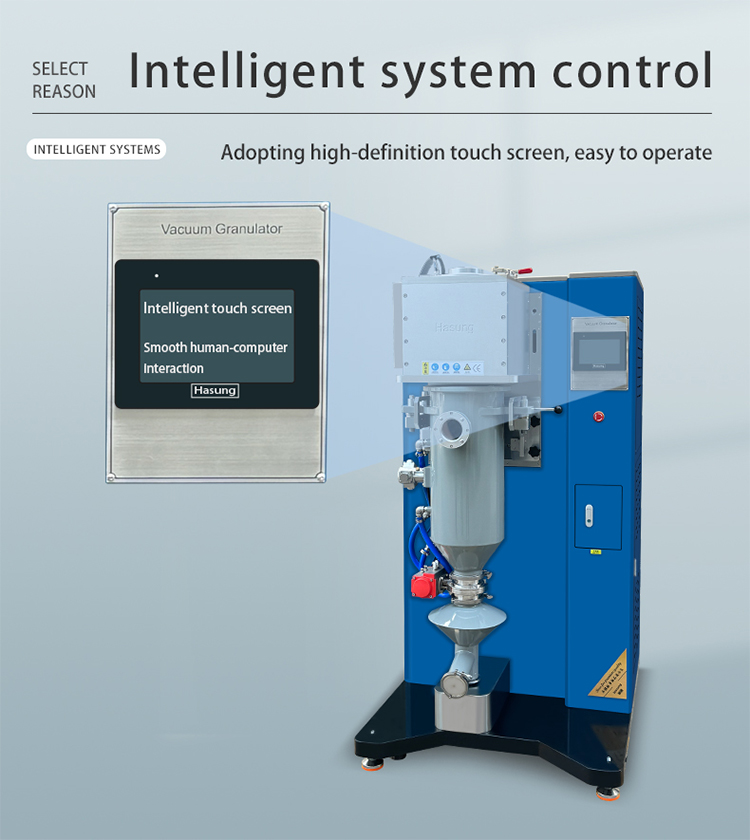

Txoj kev ua haujlwm | Auto hom thiab phau ntawv hom ob qho tib si | |||

Tswj qhov system | 10" Taiwan Weinview Kov npo + Siemens PLC ntse tswj qhov system | |||

Hom cua txias | Dej chiller (muag nyias) los yog dej ntws | |||

Qhov ntev | 1150 * 970 * 1860mm 1250 * 970 * 1950mm | |||

Qhov hnyav | kwv yees. 450kg ib. 5 50kg | |||

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115