Zoo Hasung - Jewelry Casting Machinery Precious Metals Kub Silver Copper Nqus Granulating Tshuab Chaw tsim tshuaj paus

Hasung - Cov Khoom Siv Ua Hniav Kub Kub Nyiaj Tooj Liab Tshuab Nqus Tsev Granulating Tshuab piv rau cov khoom zoo sib xws hauv khw, nws muaj cov txiaj ntsig zoo tshaj plaws hauv kev ua tau zoo, zoo, tsos, thiab lwm yam, thiab muaj lub koob npe zoo hauv khw. Hasung sau cov qhov tsis zoo ntawm cov khoom yav dhau los, thiab txhim kho lawv tas li. Cov lus qhia ntawm Hasung - Cov Khoom Siv Ua Hniav Kub Kub Nyiaj Tooj Liab Tshuab Nqus Tsev Granulating Tshuab tuaj yeem hloov kho raws li koj xav tau.

Cov thev naus laus zis siab heev tau siv rau cov txheej txheem tsim khoom ntawm cov tshuab ua hniav nyiaj hniav kub Precious hlau Kub nyiaj Tooj Liab Nqus Tsev Granulating tshuab. Nrog rau kev nthuav dav ntawm cov khoom ua tau zoo, nws cov ntawv thov ntau yam dav dua thiab tau nthuav dav mus rau thaj chaw (s) ntawm Cov Tshuab Casting Hlau.

Shenzhen Hasung Precious Metals Equipment Co., Ltd tseem nco txog lub sij hawm thaum peb ua tiav cov khoom tshiab - Cov hniav nyiaj hniav kub casting machinery Precious hlau kub nyiaj tooj liab nqus Granulating tshuab. Cov khoom yog kiag li tshiab thiab muaj ib yam dab tsi txawv nyob rau hauv nws. Nws yog ilv tsim los ua raws li kev lag luam tus qauv. Hais txog nws tus qauv tsim, Jewelry casting machinery Precious hlau Kub nyiaj Copper Nqus Granulating tshuab yog tsim los ntawm ib pab neeg ntawm peb cov neeg tsim qauv uas ib txwm nyob ze rau kev lag luam sib txawv thiab ceev faj txog cov kev hloov pauv.

| Qhov Chaw Keeb Kwm: | Guangdong, Suav teb | Qhov xwm txheej: | Tshiab, 100% Brand Tshiab |

| Tshuab Hom: | casting | Video tawm-kev tshuaj xyuas: | Muab |

| Machinery Test Report: | Muab | Hom kev lag luam: | Cov khoom tshiab 2020 |

| Warranty ntawm cov khoom tseem ceeb: | 2 xyoo | Core Components: | PLC, Cav, Tsav |

| Hom Lub Npe: | Hasung | Voltage: | 220V/380V |

| Lub zog: | 8KW 15KW, 8KW | Warranty: | 2 xyoo, 2 xyoos |

| Ntsiab Muag Khoom: | Kev tswj qhov kub thiab txias | Qhov chaw Showroom: | Tsis muaj |

| Siv tau Industries: | Chaw tsim tshuaj paus, Zog & Mining, Lwm yam | Qhov hnyav (KG): | 120 |

| Feature: | Zoo tshaj | Kev Siv Hluav Taws Xob: | 380V |

| Muaj peev xwm: | 2kg ua | Daim ntawv thov: | Kub, nyiaj, tooj liab, alloys |

| Qhov Loj: | 880x680x1530mm | Qhov hnyav: | 120 kg |

| Ntawv pov thawj: | ISO CE |

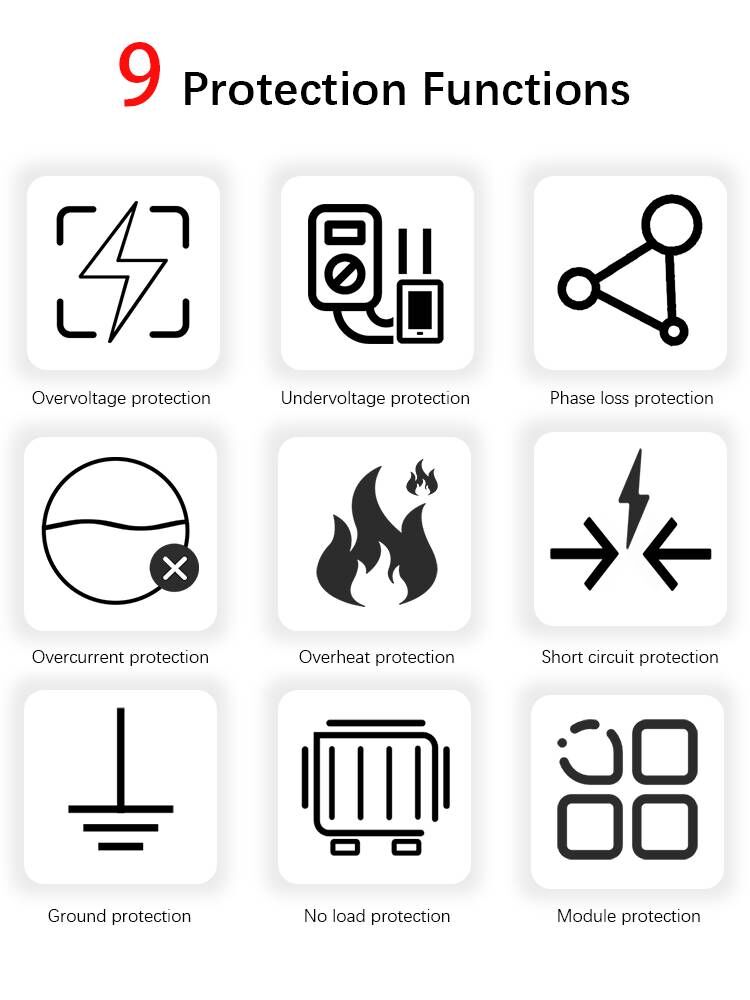

Siv cov cuab yeej siv hluav taws xob ntau zaus, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv thev naus laus zis, nws tuaj yeem yaj hauv lub sijhawm luv luv, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, thiab kev ua haujlwm siab. 2. Cov hom kaw + lub tshuab nqus tsev / inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab tiv thaiv kev sib xyaw ntawm impurities. Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim. 3. Siv lub kaw lus + lub tshuab nqus tsev / inert roj tiv thaiv melting chamber, melting thiab nqus tsev yog ua nyob rau tib lub sij hawm, lub sij hawm yog halved, thiab ntau lawm efficiency yog heev txhim khu kev qha. 4. Melting nyob rau hauv ib tug inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon crucible yuav luag negligible. 5. Nrog rau electromagnetic stirring muaj nuj nqi nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim. 6. Nws txais qhov yuam kev pov thawj (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim rau kev siv. 7. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C). HS-GR lub tshuab nqus tsev casting cov cuab yeej yog tsim los ntawm nws tus kheej thiab tsim nrog cov cuab yeej siv siab heev thiab muaj nplooj siab rau melting thiab casting kub, nyiaj, tooj liab. 9. Cov cuab yeej siv no siv PID kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo lub cev muaj zog tsav thiab lwm yam khoom lag luam muaj npe nrov hauv tsev thiab txawv teb chaws. 10. Melting, electromagnetic stirring, thiab tub yees nyob rau hauv ib tug kaw + lub tshuab nqus tsev / inert gas tiv thaiv melting chav tsev, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj pores, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

- Hasung Precious Metals Equipment zoo

1. Cov khoom muaj xim sib xws thiab tsis muaj kev sib cais:

Lub porosity yog txo, thiab qhov ceev yog siab dua thiab tas li, txo cov kev ua haujlwm tom qab thiab txo qhov poob.

2. Cov khoom zoo dua fluidity thiab pwm filling, txo kev txaus siab txaus ntshai:

Kev vibration txhim kho cov khoom ntws, thiab cov qauv ntawm cov khoom yog compact dua. Txhim kho cov duab filling thiab txo qhov kev pheej hmoo ntawm kub tawg

3. Cov nplej loj yog txo mus rau 50%:

Solidify nrog ib tug finer thiab ntau uniformity

4. Cov khoom siv zoo dua thiab ruaj khov dua:

Lub zog tensile thiab elasticity tau nce los ntawm 25%, thiab cov kev ua haujlwm tom qab tau txhim kho.

Vim li cas koj thiaj xaiv Hasung Vaccum Pressured Casting Tshuab?

Hasung Nqus Casting tshuab piv rau lwm lub tuam txhab

1. Nws yog qhov sib txawv loj. lwm lub tuam txhab nqus tsev yog tswj los ntawm lub sijhawm.Lawv tsis yog lub tshuab nqus tsev.Lawv cia li tso nws lub cim.Thaum lawv nres twj, nws tsis yog lub tshuab nqus tsev.Peb cov twj tso kua mis mus rau qhov teeb tsa lub tshuab nqus tsev thiab tuaj yeem tswj tau lub tshuab nqus tsev.

2. Nyob rau hauv lwm yam lus, dab tsi lawv muaj yog lub tshuab nqus tsev teeb lub sij hawm.Piv txwv li, ntxiv inert roj tom qab ib feeb los yog 30 vib nas this yog tsis siv neeg.Yog hais tias nws tsis ncav cuag lub nqus tsev vacuum, nws yuav hloov mus rau inert roj. Nws yog qhov tseeb, cov roj inert thiab huab cua tau noj tib lub sijhawm. Nws tsis yog lub tshuab nqus tsev kiag li. Lub tshuab nqus tsev tsis tuaj yeem khaws cia rau 5 feeb.Hasung tuaj yeem tuav lub tshuab nqus tsev rau ntau tshaj nees nkaum teev.

3.Peb tsis zoo ib yam. Peb tau kos lub tshuab nqus tsev. Yog tias koj nres lub tshuab nqus tsev twj, nws tseem tuaj yeem tuav lub tshuab nqus tsev. Rau ib lub sij hawm ntawm lub sij hawm, peb yuav ncav cuag lub teeb Tom qab teeb tsa tus nqi, nws tuaj yeem hloov mus rau kauj ruam tom ntej thiab ntxiv roj inert

4.Hasung thawj qhov chaw yog los ntawm cov neeg paub zoo hauv Nyij Pooj thiab German hom.

Cov ntaub ntawv technical

| Qauv No. | HS-GR1 | HS-GR2 | HS-GR3 | HS-GR4 | HS-GR5 | HS-GR6 | HS-GR8 | HS-GR10 | HS-GR30 | HS-GR50 |

| Qhov hluav taws xob | 220V, 50/60Hz ib theem | 380V, 50/60Hz 3 theem | ||||||||

| Induction Generator Fais Fab | 8KW | 15KW | 20KW | 30KW/40KW | ||||||

| Peev xwm (Au) | 1kg ua | 2kg ua | 3kg ua | 4kg ua | 5kg ua | 6kg ua | 8kg ua | 10kg ua | 30kg ua | 50kg ua |

| Melting ceev | 2-3 feeb. | 3-6 feeb. | 2-3 feeb. | 3-6 feeb. | 5-8 feeb. | 2-3 feeb. | 3-6 feeb. | 5-8 feeb. | 5-8 feeb. | 10-20 feeb. |

| Max kub | 1500℃ | |||||||||

| Temp raug | ±1°C | |||||||||

| Daim ntawv thov | Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys | |||||||||

| Inert Gas | Argon / Nitrogen | |||||||||

| Cov qoob loo loj | 1.8-4.0 hli | |||||||||

| Hom cua txias | Dej ntws / dej chiller (muag cais) | |||||||||

| Tswj qhov system | Mitsubishi PLC + Tib neeg-tshuab interface ntse tswj qhov system (yeem) | |||||||||

| Lub tshuab nqus tsev | Lub tshuab nqus tsev nqus tsev nqus tsev vacuum / German Vacuum Pump, Nqus degree-100KPA | |||||||||

| Cheebtsam | Siv lub ntiaj teb nto moo hom xws li Siemens, AirTec, SMC, Schneider, Omron, thiab lwm yam. | |||||||||

| Qhov ntev | 880x680x1560mm | |||||||||

| Qhov hnyav | kwv yees. 120 kg | kwv yees. 150 kg | kwv yees. 180kg ib | kwv yees. 280kg ua | ||||||

Kub Silver Granulating Txheej Txheem:

Shenzhen Hasung Precious Metals Equipment Co., Ltd.

Peb lub tuam tsev R & D yeej ib txwm ua haujlwm rau kev tsim cov cuab yeej casting thiab melting technologies kom haum rau peb qhov kev hloov pauv tsis tu ncua rau Kev Lag Luam Tshiab Cov Khoom Siv, Aerospace, Kub Mining, Hlau Minting Kev Lag Luam, Kev Tshawb Fawb Kev Tshawb Fawb, Kev Tsim Kho sai sai, Jewellery, thiab Duab puab. Peb muab cov kev daws teeb meem zoo tshaj plaws rau cov neeg siv khoom. Peb tuav lub hauv paus ntsiab lus ntawm "kev ncaj ncees, zoo, kev koom tes, yeej-yeej" lub tswv yim kev lag luam, cog lus los tsim cov khoom lag luam thawj zaug thiab cov kev pabcuam.Peb ib txwm ntseeg tias kev hloov pauv lub neej yav tom ntej.

Peb tshwj xeeb hauv kev tsim thiab tsim cov kev cai tiav kev daws teeb meem. Peb siv zog ua kom cov txheej txheem tiav sai dua thiab pheej yig dua. Txais tos tuaj xyuas peb

Cov neeg muas zaub

Hais txog Hasung

Lub tuam txhab zoo

Ntau tshaj 30 patents rau tshuab.

Peb muab kev pabcuam ib-nres rau cov khoom siv hlau zoo nkauj casting.

Nws yog dav siv nyob rau hauv precious hlau refining, precious hlau smelting, precious hlau tuav, hlaws dai, hmoov trading, kub jewellery, thiab lwm yam.

Peb muab kev tsim qauv dawb rau koj cov graphite pwm ua ntej xaj peb cov tshuab.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115