Hasung - Kub Bar Ua Tshuab Kub Bullion Nqus Casting Equipment 8 PCS 1kg Bar Hoobkas khoom hauv Tshuag

Qhia txog lub tshuab ua kub Hasung, qhov kev daws teeb meem zoo tshaj plaws rau kev tsim cov kub thiab nyiaj zoo yooj yim thiab ua haujlwm tau zoo. Lub tshuab niaj hnub no yog tsim los rau kev ua haujlwm tsis siv neeg, ua rau nws zoo tagnrho rau cov neeg pib tshiab thiab cov kws tshaj lij. Nrog nws lub interface yooj yim siv thiab kev tswj hwm yooj yim, cov khoom siv nqus tsev kub kub yooj yim heev rau kev ua haujlwm, cia koj tsim cov kub thiab nyiaj zoo meej nrog kev siv zog tsawg kawg nkaus. Nws lub peev xwm yaj sai thiab kev ua haujlwm siab ua kom koj tuaj yeem tsim cov kub ntau hauv lub sijhawm luv luv, ua rau nws zoo tagnrho rau kev tsim khoom me me thiab loj.

Lub tshuab nqus tsev kub cov thev naus laus zis siab heev thiab kev tsim kho kom raug tau lees tias cov txiaj ntsig zoo meej txhua lub sijhawm, tsim cov tuav zoo tshaj plaws uas ua tau raws li cov qauv kev lag luam. Txawm koj yog tus kws ua hniav nyiaj hniav kub, tus kws ntaus kub lossis tus neeg muag khoom muaj nqis, lub tshuab ua kub Hasung yog lub cuab yeej zoo meej los txhim kho koj cov txheej txheem tsim khoom thiab xa cov txiaj ntsig zoo rau koj cov neeg siv khoom. Ntxiv rau qhov kev ua tau zoo tshaj plaws, lub tshuab nqus tsev hlau Hasung tau tsim los nrog kev nyab xeeb thiab kev ua haujlwm ntev. Nws cov qauv ruaj khov thiab cov khoom siv txhim khu kev qha ua rau nws yog kev nqis peev ntev uas yuav txuas ntxiv ua kom tau raws li koj cov kev xav tau ntau xyoo tom ntej.

Paub txog qhov yooj yim, ceev thiab raug ntawm Hasung lub tshuab nqus tsev kub casting thiab coj koj cov khoom kub thiab nyiaj bar mus rau qib tom ntej. Nrog nws cov kev sib xyaw ua ke ntawm kev ua haujlwm tsis siv neeg tag nrho, yooj yim siv, yaj sai, ua haujlwm tau zoo thiab cov txiaj ntsig zoo tshaj plaws, lub tshuab no yog qhov kev xaiv zoo tshaj plaws rau txhua tus neeg uas tab tom nrhiav kom nce lawv cov peev xwm tsim cov hlau muaj nqis.

Shenzhen Hasung yeej ib txwm txuas qhov tseem ceeb rau cov ntsiab lus mob ntawm kev lag luam. Cov khoom lag luam uas tau tsim tawm tshiab kub lub tshuab nqus tsev casting khoom yog tsim tshwj xeeb los daws qhov mob cov ntsiab lus ntawm kev lag luam, uas zoo kawg nkaus daws qhov mob cov ntsiab lus ntawm kev lag luam thiab tau txais kev zoo siab los ntawm kev ua lag luam. Nws tau raug pov thawj tias cov thev naus laus zis siab kawg tuaj yeem pab txhawb rau kev tsim cov txheej txheem ua haujlwm siab. Nyob rau hauv daim teb (s) ntawm precious hlau casting, Hoobkas muab hlau nqus casting tshuab rau 1-15kg kub nyiaj bullion casting yog dav txais los ntawm cov neeg siv. Hasung ib txwm ua raws li lub hauv paus ntsiab lus ntawm 'tsim txiaj ntsig rau cov neeg siv khoom thiab nqa cov txiaj ntsig rau cov neeg muaj feem'. Nyob rau hauv tus txheej txheem ntawm txoj kev loj hlob, peb tsom ntsoov rau qhov zoo thiab xyuas kom meej tias tsis muaj flawless khoom xa mus rau cov neeg muas zaub.

First-Class Level Quality thiab Technology rau Precious Hlau Nqus Casting Tshuab Chaw tsim tshuaj paus nyob rau hauv Suav teb.

Technical Specifications:

| Qauv No. | HS-GV4 | HS-GV8 | HS-GV15 | HS-GV30 |

| Qhov hluav taws xob | 380V, 50/60Hz 3 Phase | |||

| Hwj chim | 50KW / 65KW TSI | 70KW / 80KW TSI | ||

| Zuag qhia tag nrho Casting Time | 10-15 feeb. | 15-20 feeb. | 12-15 feeb. | 20-30 feeb. |

| Peev xwm (Au) | 4kg: 4 pcs 1kg, 8pcs 0.5kg lossis ntau dua. | 8kg: 8 pcs 1kg, lossis ntau dua | 15kg: 1pcs 15kg, lossis 5pcs 1kg lossis ntau dua | 1pcs 30kg lossis ntau dua. |

| Max kub | 1500°C | |||

| Inert gas | Argon / Nitrogen | |||

| Dej txias txias | 20-25°C | |||

| Kev siv hlau | Kub nyiaj | |||

| Lub tshuab nqus tsev twj | Kev ua tau zoo tus nqi nqus tsev / German Vacuum Pump, Vacuum degree-100KPA (yeem) | |||

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | |||

| Tswj qhov system | 10 "Taiwan Weinview / Siemens PLC + Tib neeg-tshuab interface ntse tswj system lossis Siemens PLC kov vaj huam sib luag | |||

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws | |||

| Qhov ntev | 1460X720X1010mm / 1530X800X1060mm | |||

| Qhov hnyav | 380kg / 450kg | |||

Nqe lus piav qhia :

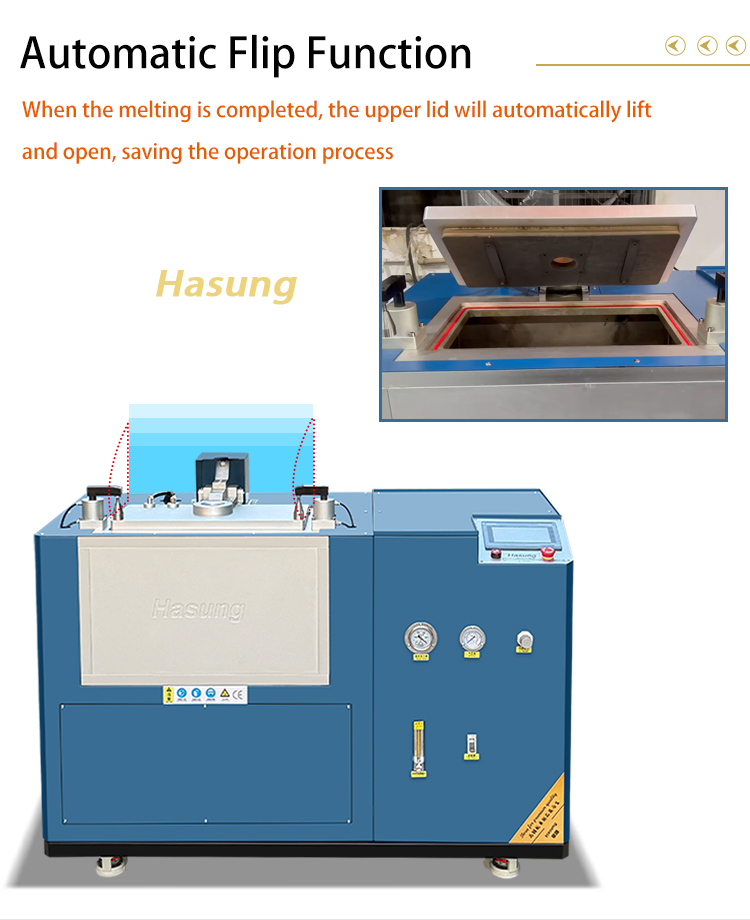

1. Qhov zoo tshaj plaws tag nrho tsis siv neeg muaj nuj nqis hlau casting system, Ib qho tseem ceeb tuaj yeem ua tiav tag nrho cov txheej txheem casting. Tsis siv neeg kaw lub hau - Tsis siv neeg inert roj thiab nqus tsev vacuum - Tsis siv neeg casting thiab txias - Tsis siv neeg qhib lub hau - Tshem tawm qhov ci ntsa iab kub.

2. Tswj qhov system: Taiwan 10 "PLC + Tib neeg-tshuab interface ntse tswj qhov system (Siemens PLC kov npo yog xaiv tau)

3. Siv German IGBT induction cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv thev naus laus zis, nws tuaj yeem yaj hauv lub sijhawm luv luv, txuag hluav taws xob, thiab kev ua haujlwm siab.

4. Melting nyob rau hauv lub tshuab nqus tsev thiab inert roj tiv thaiv atomophere uas muaj peev xwm tiv thaiv oxidation ntawm molten raw cov ntaub ntawv thiab tsis shrinkage, npuas, thiab lwm yam. Cov cuab yeej no yog tsim rau lub casting ntawm high-purity kub cov ntaub ntawv nyiaj.

5. Nrog rau electromagnetic stirring muaj nuj nqi nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

6. Nws txais qhov yuam kev pov thawj (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim rau kev siv.

7. Cov khoom siv tshuab kub kub no siv Twaiwan PLC kev tswj hwm qhov system lossis Siemens, Nyiv SMC / AirTec pneumatic Cheebtsam, Lub teb chaws Yelemees Omron, Schneider thiab Panasonic servo tsav tsav thiab lwm yam khoom siv hauv tsev thiab txawv teb chaws.

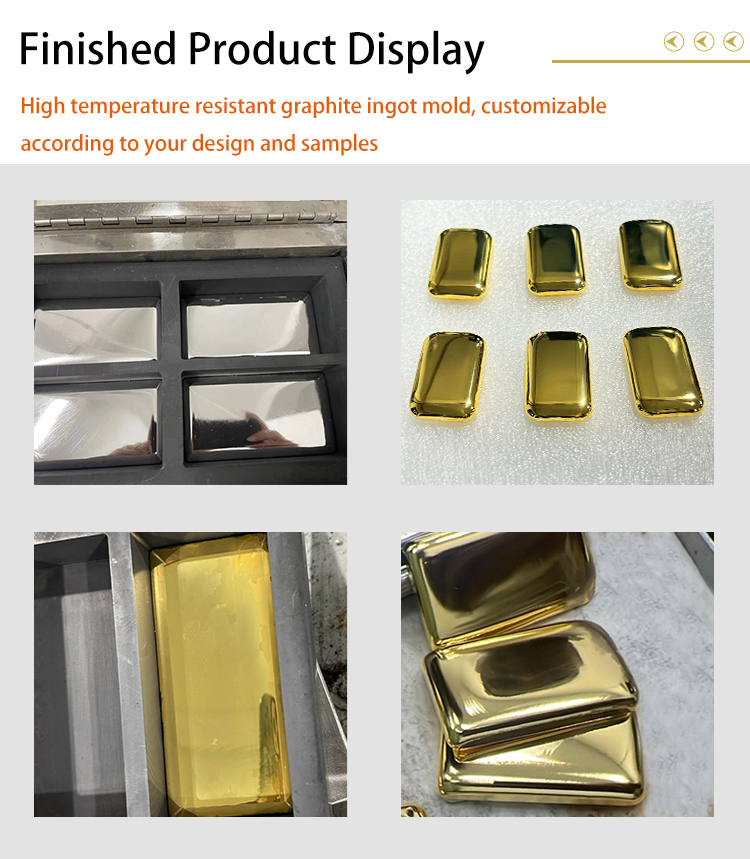

8. Tsis muaj oxidation, poob qis, tsis muaj porosity, tsis muaj kev sib cais ntawm cov xim, thiab zoo nkauj tsos.

Vim li cas koj thiaj xaiv Hasung Gold Bullion Nqus Casting Equipment?

Hasung nqus kub bar casting tshuab piv rau lwm lub tuam txhab:

1.Advanced Technology: Siv cov cua sov induction kom ua tau zoo ntawm cov hlau muaj txiaj ntsig zoo. Cov cuab yeej no muab cov peev txheej cua kub ceev, kev siv hluav taws xob siab, thiab tswj qhov kub thiab txias. Nws tuaj yeem nce qhov kub ntawm cov hlau sai sai rau lawv cov ntsiab lus melting, kom ntseeg tau tias cov cua sov tsis sib xws thiab tsis tshua muaj thermal poob.

2.High-Quality Casting: Tsim lub tshuab nqus tsev ib puag ncig thaum lub sij hawm muaj nuj nqis hlau casting txheej txheem, tiv thaiv oxidation thiab paug ntawm cov hlau. Qhov no ua rau kub bullion tuav nrog siab purity thiab zoo heev nto zoo.

3.Automation: nta tag nrho tsis siv neeg ua haujlwm, txo cov kev cuam tshuam tib neeg thiab txo qhov kev pheej hmoo ntawm kev ua yuam kev. Nruab nrog cov sensors siab heev thiab cov tshuab tswj xyuas uas saib xyuas thiab kho ntau yam tsis nyob hauv lub sijhawm.

4.Precision: Ua haujlwm siab-precision casting pwm kom raug shaping kub bullion tuav. Cov pwm ua kom nruj me ntsis kam rau ua thiab du nto.

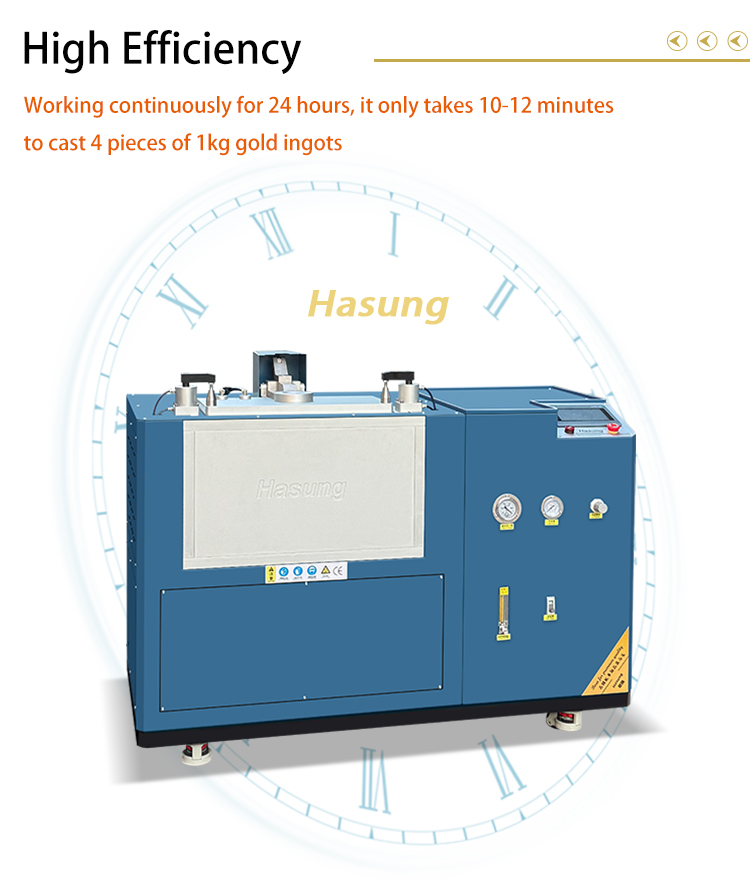

5.Efficiency: Txhim kho kev tsim khoom thiab txo cov khoom pov tseg.

6.Versatility: Muaj peev xwm tuav ntau hom thiab specifications ntawm cov ntaub ntawv kub, ua tau raws li cov neeg xav tau ntau yam.

Nta:

✔ 24 teev ntawm kev ua haujlwm tas mus li yuav ua tau raws li koj lub hom phiaj ua haujlwm ntev.

✔ Tswj tau yooj yim nrog HMI interface. Tus qauv tshaj plaws, tag nrho tsis siv neeg tswj.

✔ Lub tshuab nqus tsev kub ua kom tsis txhob muaj bullion oxidation, shrinkage, thiab dej nthwv dej hauv qab lub tshuab nqus tsev.

✔ Cov txheej txheem casting yog tag nrho kaw kom tsis txhob muaj nplaim taws rau kev nyab xeeb ntawm cov neeg ua haujlwm.

✔ Lub ntsej muag du thiab ci ntsa iab uas tuaj yeem txhim kho koj cov pob txha zoo

✔ Lub tshuab nqus tsev hlau hlau txuag 3 zaug argon dua li lwm tus neeg sib tw.

✔ Lub tshuab nqus tsev nruj yog ntau tshaj 18 teev thaum nres lub tshuab nqus tsev, nws txhais tau tias lub tshuab nqus tsev yog qhov zoo tshaj plaws.

Taw qhia Hasung Kub Bar Nqus Casting Tshuab

Txoj kev daws teeb meem zoo tshaj plaws rau kev tsim cov khoom tsis zoo, cov khoom kub zoo. Lub tshuab thev naus laus zis no yog tsim los tsim cov iav zoo li cov noodles uas tsis muaj shrinkage los yog pores, ua kom tiav zoo meej txhua lub sijhawm. Txawm hais tias koj yog tus neeg muag khoom kub lossis cov muag kub, cov khoom siv yuav tsum muaj yuav hloov pauv koj cov txheej txheem tsim khoom thiab txhim kho cov khoom zoo.

Ntxiv rau qhov ua tau zoo tshaj plaws, lub tshuab no yog tsim los nrog kev ua haujlwm zoo thiab siv tau yooj yim hauv siab. Nws cov neeg siv-phooj ywg interface thiab intuitive tswj ua haujlwm yooj yim, cia cov neeg ua haujlwm tsom mus rau cov txheej txheem tsim khoom yam tsis muaj teeb meem tsis tsim nyog. Qhov no streamlines workflow thiab maximizes productivity, thaum kawg txuag nqi thiab txhim kho tag nrho cov efficiency.

Tsis tas li ntawd, lub tshuab nqus tsev kub kub lub tshuab nqus tsev casting muaj peev xwm tiv taus qhov hnyav ntawm kev siv tas li hauv qhov hnyav ntau lawm. Nws cov rugged kev tsim kho thiab cov khoom siv ruaj khov ua kom muaj kev ntseeg tau ntev, txo qis qis thiab kev saib xyuas yuav tsum tau ua. Qhov kev ntseeg siab no yog qhov tseem ceeb rau cov lag luam uas vam khom cov khoom lag luam kom tau raws li kev xav tau ntawm kev lag luam thiab tswj kom muaj kev sib tw kom zoo dua.

Rau cov refiners kub, qhov no kub bullion nqus tsev casting khoom muaj qhov zoo tshaj plaws hauv kev tsim cov kub purity kub. Kev tswj xyuas meej ntawm cov txheej txheem casting kom ntseeg tau tias impurities raug txo qis, ua rau cov pas nrig ua tau raws li cov qauv purity nruj tshaj plaws. Qhov no yog qhov tseem ceeb rau kev tswj xyuas kev ncaj ncees ntawm cov txheej txheem refining thiab xa cov khoom kub uas hais kom tus nqi hauv khw.

Ib yam li ntawd, cov neeg lag luam kub tuaj yeem siv lub tshuab no kom sib txawv lawv cov khoom thiab tsim lub koob npe nrov rau kev ua tau zoo. Lub peev xwm los tsim cov khoom kub zoo meej ua rau lawv sib nrug ntawm lawv cov neeg sib tw thiab txhawb kev ntseeg siab rau lawv cov neeg siv khoom. Txawm hais tias siv rau lub hom phiaj peev lossis rau kev tsim cov hniav nyiaj hniav kub, qhov zoo tshaj plaws ntawm cov tshuab tsim kub yog qhov muag muag.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115