Zoo tshaj Hasung - Kev Taw Qhia Pouring Tilting Induction Melting Rauv nrog 1kg ~ 10kg rau Kub Nyiaj

Kev siv cov thev naus laus zis siab heev ua rau muaj kev nyab xeeb thiab ua haujlwm zoo ntawm cov khoom. Tam sim no, 1kg txog 10kg Kev Taw Qhia tilting hom melting rauv Kub smelting Rauv tilting crucible rauv tau dav pom nyob rau hauv daim ntawv thov Scope(s) ntawm Lwm Cov Hlau & Metallurgy Machine.

Hasung - 1kg txog 10 kg phau ntawv Tilting Pouring Melting Rauv Kub Smelting Rauv Tilting Crucible Melting Rauv piv nrog cov khoom zoo sib xws ntawm kev ua lag luam, nws muaj qhov zoo sib xws ntawm kev ua tau zoo, zoo, zoo li, thiab lwm yam, thiab nyiam lub koob npe nrov hauv kev ua lag luam.Hasung summarizes qhov tsis xws luag ntawm cov khoom lag luam yav dhau los. Cov lus qhia tshwj xeeb ntawm Hasung - 2kg rau 1kg Kev Taw Qhia Tilting Pouring Melting Rauv Kub Smelting Rauv Tilting Crucible Melting Rauv tuaj yeem kho raws li koj xav tau.

ery.

Thawj-Class Qib Zoo thiab Tshuab rau Precious Hlau Khoom Chaw Tsim Tshuaj nyob hauv Suav teb.

PRODUCT SPECIFICATIONS:

| Qauv No. | HS-TFQ2 | HS-TFQ3 | HS-TFQ4 | HS-TFQ5 | HS-TFQ6 | ||||

| Qhov hluav taws xob | 380V, 50Hz, 3 theem | ||||||||

| Hwj chim | 15KW | 15KW | 20KW | ||||||

| Max Temp | 1600 ° C | ||||||||

| Peev xwm (Au) | 2kg ua | 3kg ua | 4kg ua | 5kg ua | 6kg ua | ||||

| Lub sij hawm yaj | 2-3 feeb. | 2-4 feeb. | 2-5 feeb. | 3-6 feeb. | |||||

| Max. kub | 1600 degree celsius | ||||||||

| Daim ntawv thov | Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys | ||||||||

| Txoj kev ua kom txias | Dej chiller (muag cais) los yog dej khiav (dej twj tso kua mis) | ||||||||

| Cua sov tshuab | Lub teb chaws Yelemees IGBT Induction cua sov | ||||||||

| Lub sijhawm ua haujlwm | 24 teev ua haujlwm tsis tu ncua | ||||||||

| Qhov ntev | 90 x 48 x 100 cm | ||||||||

| Qhov hnyav | 90kg ua | 110kg ib | |||||||

Nqe lus piav qhia:

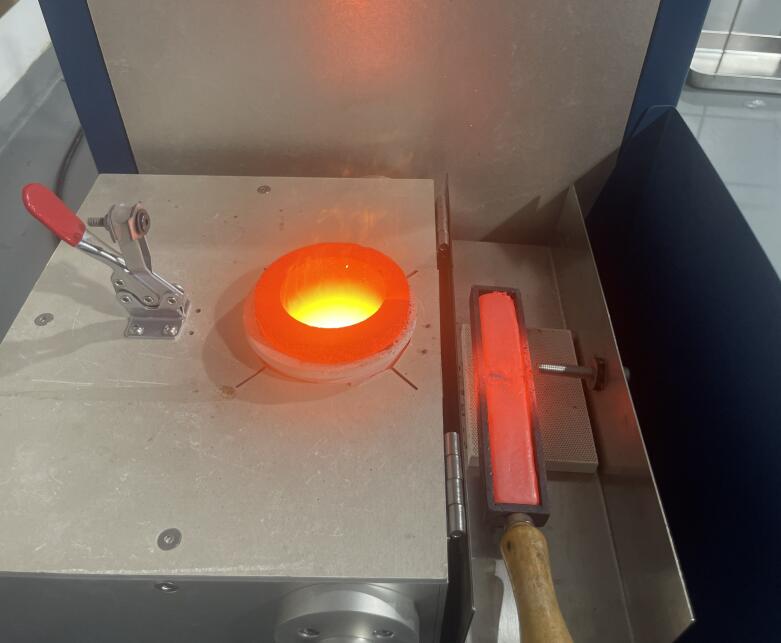

Tilting Melting Rauv rau melting ntau ntau ntawm hlau rau hauv ingots los yog bullions.

Cov cav tov no yog tsim los rau melting ntau ntau, piv txwv li nyob rau hauv lub kub recycle Hoobkas rau loj muaj peev xwm melting ntawm 50kg los yog 100kg ib batch.

Hasung TF series - sim thiab sim nyob rau hauv foundries thiab precious hlau refining pawg.

Peb tilting smelting furnaces yog siv nyob rau hauv ob qhov chaw:1. rau melting ntau ntau ntawm hlau xws li kub, nyiaj los yog manufacturing hlau kev lag luam xws li casting scraps, 15KW, 30KW, thiab siab tshaj plaws 60KW tso zis thiab tsawg zaus tuning txhais tau tias ceev melting uas nyiam qhov zoo tshaj plaws tau los ntawm Tuam Tshoj - txawm rau loj ntim - thiab zoo heev los ntawm kev sib tov.

2. rau casting loj, hnyav Cheebtsam tom qab casting nyob rau hauv lwm yam lag luam.

Lub TF20 rau TF100 qauv, Nyob ntawm tus qauv, lub peev xwm ntawm ib tug crucible ntim ntawm 20kg mus rau 100kg rau kub, feem ntau rau precious hlau manufacturing tuam txhab uas muag.

MDQ series tilting furnaces yog tsim los rau ob qho tib si platinum thiab kub, tag nrho cov hlau xws li platinum, palladium, stainless hlau, kub, nyiaj, tooj liab, alloys thiab lwm yam, tuaj yeem yaj hauv ib lub tshuab los ntawm kev hloov crucibles nkaus xwb.Hom furnaces no zoo heev rau platinum melting, yog li thaum pouring, tshuab ua kom cua sov kom txog thaum koj yuav luag tas, ces ncuav shuts cia thaum yuav luag tiav.

FEATURES AT A GLANCE

Qhia me me induction melting rauv rau smelting kub, nyiaj thiab tooj liab

Puas yog koj nyob hauv kev lag luam rau kev txhim khu kev qha, zoo kub, nyiaj lossis tooj liab smelting tov? Peb lub qhov cub me me induction melting yog qhov koj xaiv zoo tshaj. Cov cuab yeej txiav no yog tsim los ua kom tau raws li cov kev xav tau ntawm cov jewelers, hlau fabricators thiab me me manufacturers uas xav tau ib tug melting tov uas yog ceev, nyab xeeb thiab yooj yim rau kev khiav lag luam. Nrog nws cov thev naus laus zis tshiab, muaj peev xwm yaj sai sai thiab cov neeg siv khoom tsim qauv, peb lub qhov cub me me induction melting rauv yog qhov kev xaiv zoo tshaj plaws rau cov neeg uas tab tom nrhiav kom kho lawv cov txheej txheem hlau melting.

Yooj yim rau kev khiav lag luam

Ib qho ntawm cov yam ntxwv zoo ntawm peb cov me me induction melting rauv yog lawv txoj haujlwm yooj yim. Lub tshuab hluav taws xob yog tsim los nrog cov neeg siv yooj yim hauv siab, muaj kev tswj hwm kev xav tau thiab kev sib txuas lus yooj yim uas ua rau nws yooj yim rau cov tswv lag luam kawm thiab siv. Txawm hais tias koj yog ib tus kws tshaj lij lossis tshiab rau kev ua haujlwm hlau, koj yuav txaus siab rau qhov yooj yim ntawm lub qhov cub ua haujlwm no.

Kev siv tshuab tshiab

Peb cov me me induction melting furnaces suav nrog cov kev hloov tshiab tshiab hauv induction cua sov tshuab, kom ntseeg tau tias muaj txiaj ntsig zoo thiab ua haujlwm zoo ib yam. Siv cov cua sov induction, nws muaj kev tswj qhov kub thiab txias, cov cua sov tsis sib xws, thiab ceev melting ceev. Nws yog qhov kev xaiv zoo tshaj plaws rau melting kub, nyiaj, thiab tooj liab. Nrog cov thev naus laus zis tshiab no ntawm koj lub ntsis ntiv tes, koj tuaj yeem xav tau cov txiaj ntsig zoo thiab ua tau zoo txhua lub sijhawm. Lub tshuab hluav taws xob cua sov yog 100% tsim thiab tsim los ntawm Hasung nrog kev ruaj ntseg zoo.

Melts sai

Thaum nws los txog rau hlau melting, lub sij hawm yog ntawm cov ntsiab lus, thiab peb cov me me induction melting rauv xa ceev. Nrog nws lub peev xwm melting ceev, koj tuaj yeem txo lub sij hawm nws yuav siv los yaj hlau, ua kom cov khoom tsim tau thiab ua kom tau raws li cov sijhawm teem sijhawm. Txawm hais tias koj tab tom tsim cov khoom me me lossis cov khoom loj, qhov cub hluav taws xob no yuav pab koj ua haujlwm sai thiab ua tau zoo.

Txav mus yooj yim

Portability yog ib qho kev txiav txim siab tseem ceeb rau ntau lub lag luam thiab peb cov me me induction melting rauv yog tsim los nrog qhov no hauv siab. Nws qhov loj me thiab kev tsim kho lub teeb tso cai rau nws txav tau yooj yim thiab tso rau hauv qhov chaw ua haujlwm. Txawm hais tias koj yuav tsum tau hloov koj lub qhov cub rau kev tu, tu, lossis kom haum raws li qhov xav tau ntawm kev tsim khoom, koj yuav txaus siab rau qhov yooj yim ntawm nws qhov yooj yim-rau-txav tsim.

Tilt pouring txoj kev

Ntxiv rau qhov muaj peev xwm melting, peb cov me me induction melting furnaces feature tilt pouring txoj kev kom meej, tswj cov molten hlau. Cov yam ntxwv no tshwj xeeb tshaj yog muaj txiaj ntsig rau cov ntawv thov uas xav tau qhov tseeb casting, xws li tsim cov hniav nyiaj hniav kub kev cai lossis cov khoom siv hlau zoo sib xws. Nrog lub peev xwm los qaij thiab ncuav nrog yooj yim, koj tuaj yeem tau txais cov txiaj ntsig koj xav tau effortlessly.

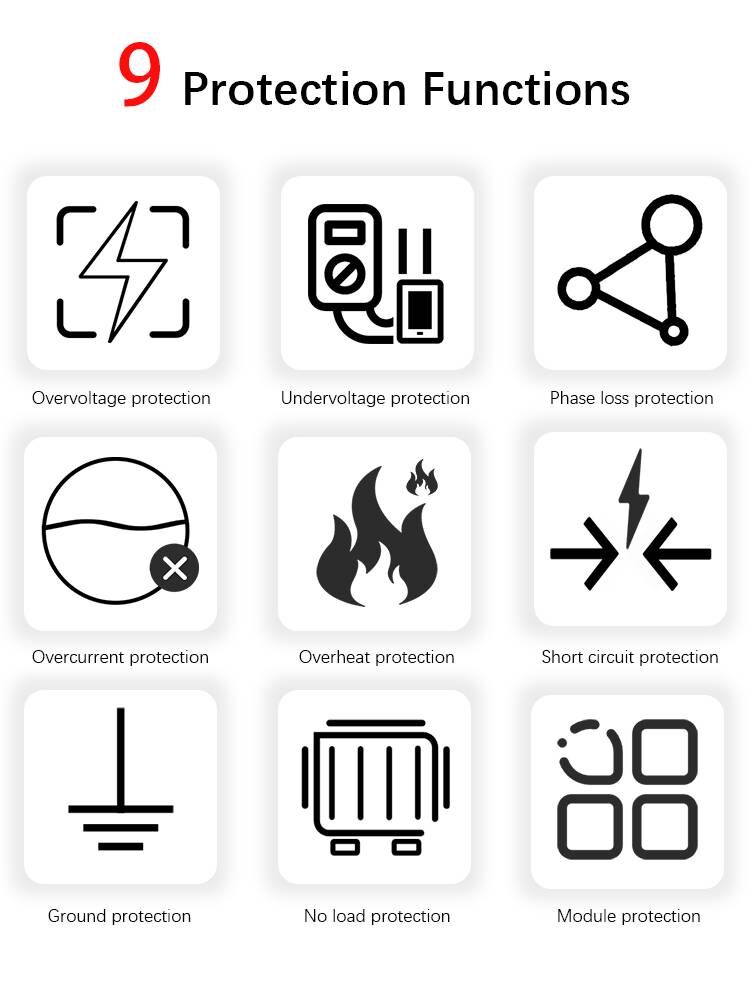

Muaj kev nyab xeeb rau cov neeg ua haujlwm

Kev nyab xeeb yog qhov tseem ceeb tshaj plaws nyob rau hauv ib puag ncig kev lag luam thiab peb cov me me induction melting rauv yog tsim los nrog cov neeg siv kev nyab xeeb hauv siab. Los ntawm nws cov insulated kev tsim kho rau built-in kev ruaj ntseg nta, lub cub tawg no muab ib qho chaw nyab xeeb rau melting hauj lwm. Cov neeg ua haujlwm tuaj yeem ua haujlwm nrog kev ntseeg siab paub tias lub cub tawg yog tsim los txo qis kev pheej hmoo thiab ua kom muaj kev nyab xeeb kev ua haujlwm.

Nyob rau hauv cov ntsiab lus, peb me me induction melting rauv rau kub, nyiaj thiab tooj liab melting yog ib tug ntau yam thiab txhim khu kev qha tshuaj rau cov lag luam thiab craftsmen uas yuav tsum tau ib tug high-kev ua tau zoo melting rauv. Nrog nws txoj haujlwm yooj yim, cov cuab yeej tshiab, muaj peev xwm yaj tau sai, tsim kom yooj yim-rau-txav, tilt pouring txoj kev thiab tsom rau tus neeg teb xov tooj kev nyab xeeb, lub tshuab hluav taws xob tau tsim kom tau raws li cov kev xav tau ntawm kev siv hlau niaj hnub no. Txawm hais tias koj tab tom melting precious hlau rau cov hniav nyiaj hniav kub ua los yog ua tooj liab rau kev lag luam siv, peb cov me me induction melting rauv yog qhov zoo tagnrho rau cov txiaj ntsig zoo. Txhim kho koj cov peev txheej hlau melting niaj hnub no nrog peb cov me me induction melting rauv.

Lub tuam txhab zoo

Cov lus nug nquag nug txog kev cai hlau casting

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115