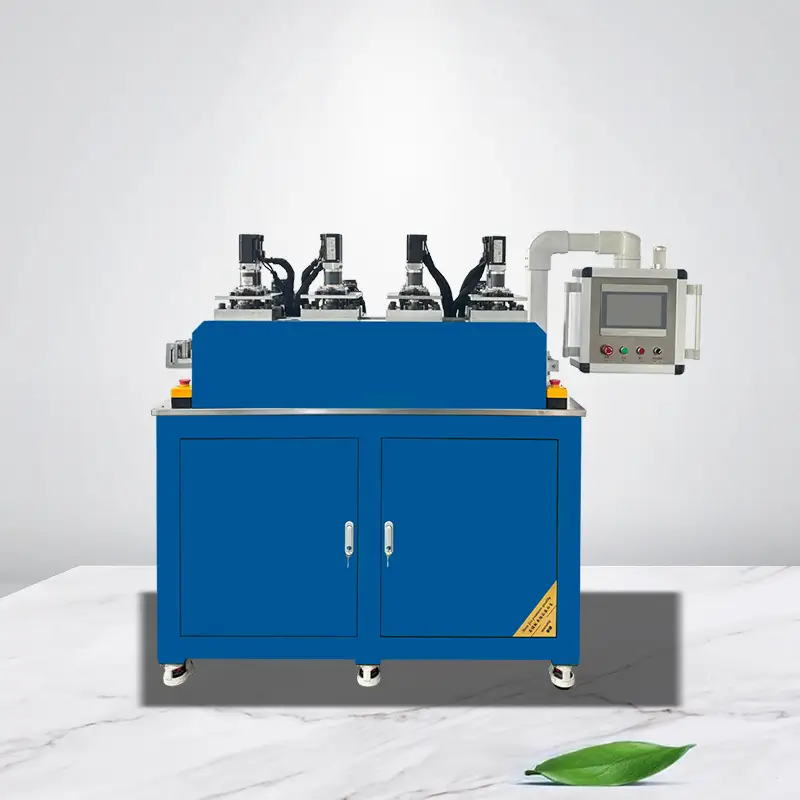

Hasung- Four Head Continuous Rolling Mill Machine

(1) Four Rolling Motors bisa diatur seragam utawa individu

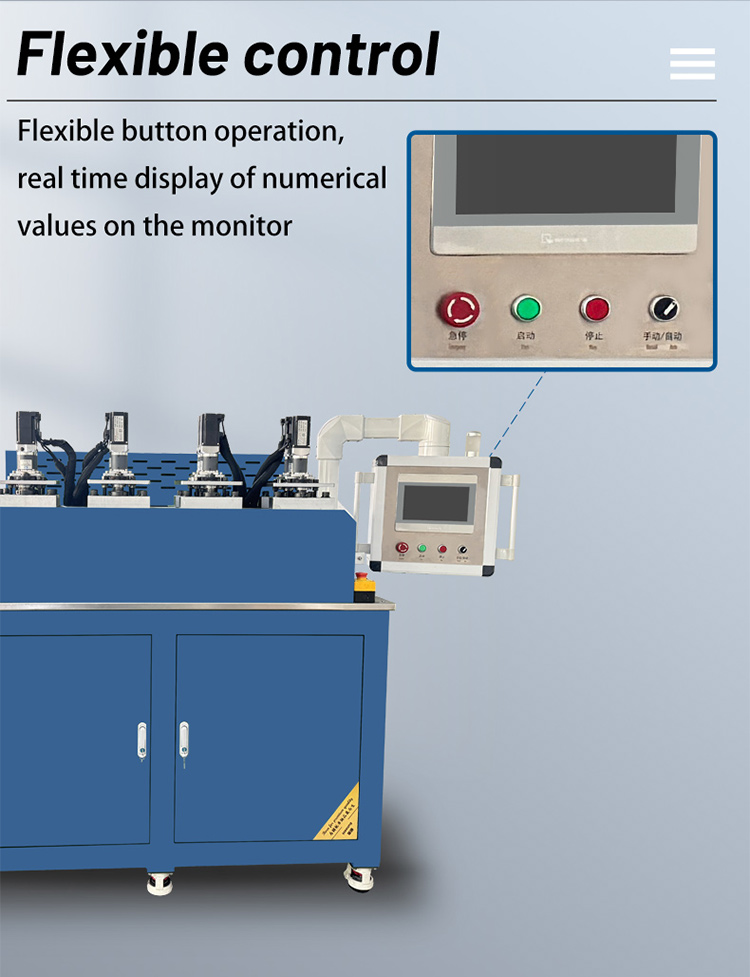

(2) Basa panel kontrol bisa diganti antarane Cina lan Inggris

(3) Tombol mandeg darurat kanggo ngimpor lan ngekspor bahan mung mandheg rotasi motor lan ora mateni daya.

(4) Rolling imbangan imbuhan lapisan bisa kontrol individu

HS-CWRM4

Kaluwihan saka peralatan:

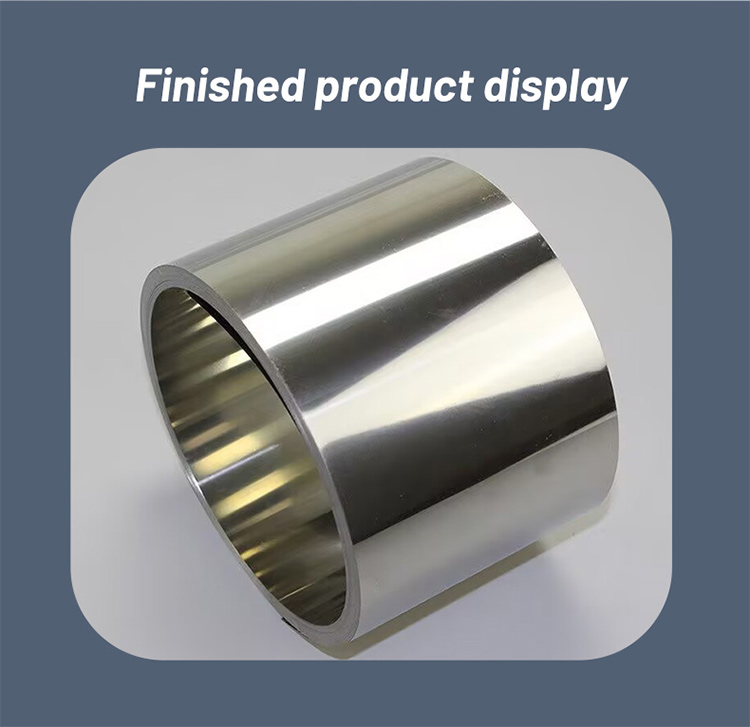

1. Pabrik rolling awet: Digawe saka bahan kekerasan dhuwur DC53, njamin umur layanan lan efisiensi sing luwih dawa

2. Kontrol cerdas: Daya rolling utama didorong dening motor servo lan dikontrol dening Siemens PLC lan layar tutul. Kontrol numerik nyetel dhuwur pabrik rolling, ngontrol kekandelan produk rampung, lan ngitung kacepetan motor servo rolling utama

3. Ngirit tenaga kerja: Mung sijine materi menyang pabrik rolling terus kanggo gawé produk rampung Dilengkapi karo fungsi weker kekurangan

4. Safety: Wilayah mbebayani ing saubengé peralatan dilengkapi tutup protèktif

5. Dhuwur tliti: Toleransi kekandelan produk rampung dikontrol ing plus utawa minus 0.01mm Ngontrol akurasi mesin komponen, ngganti bagean saka model sing padha, lan njaga kanthi cepet.

6. PLC nganggo layar tutul Weilun Tong merek Siemens 10 inci.

7. Desain tampilan peralatan iku loman lan cocok, karo pigura sheet metal dianggep karo baking Paint, lan bagean dianggep karo electroplating utawa blackening

8. Awak kandel lan desain tampilan peralatan sing loman lan cocok, sing nambah stabilitas peralatan sajrone operasi.

9. Ketat ngontrol akurasi manufaktur bagean peralatan, ngolah komponen mekanik miturut akurasi gambar, lan mesthekake interchangeability saka model sing padha, nggawe pangopènan trep, ngirit wektu, lan cepet.

10. Tambah lenga kanggo lubrication, lan nggunakake No.. 3 butter kanggo bantalan roller

11. Bantalan komponen penting yaiku bantalan sing diimpor saka merek Jerman INA, njamin presisi lan daya tahan sing dhuwur

12. Struktur sing prasaja lan kuat, pendhudhukan papan sing cilik, gangguan sing sithik, lan operasi sing gampang.

13. Akurasi komprèsi dhuwur, wajan lenga stainless steel kanggo desktop anti lenga lan anti karat, ora bocor lenga

14. Dilengkapi piranti safety mandeg darurat Panel kontrol, siji inlet lan siji stopkontak, kanthi total telung saklar mandeg darurat.

Parameter peralatan:

Sumber daya: 380V, 50HZ 3-phase

Rolling mill daya: 2.5KW x 4 sets

Nyetel daya saka klompok longkangan roller: 200W X 4 kelompok

Ukuran rol (D * L) 108 * 110mm

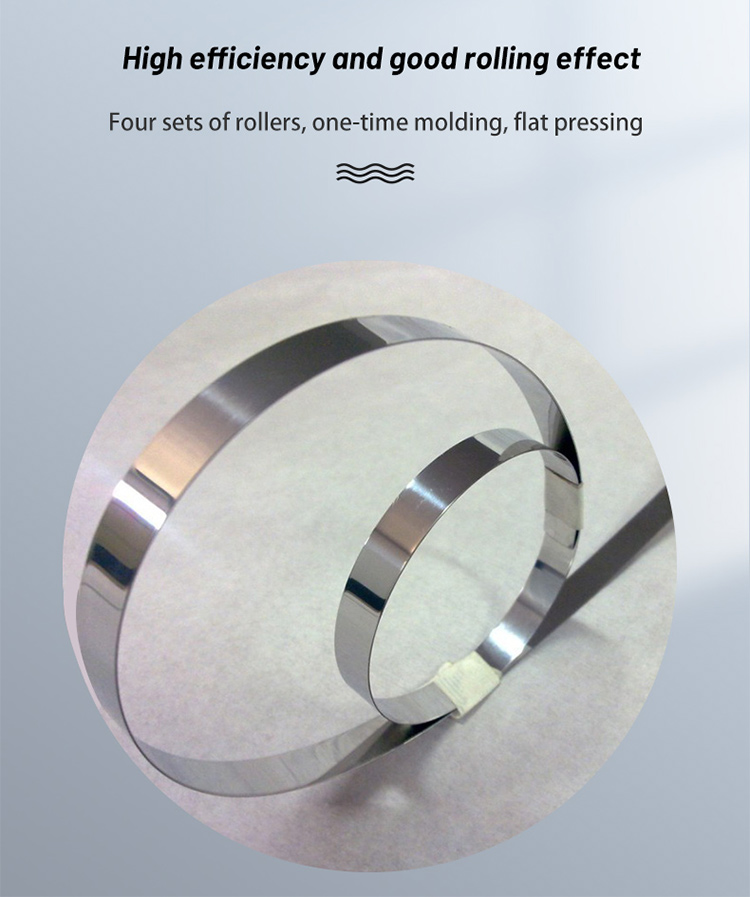

Jumlah kelompok rol: 4 kelompok

Bahan gulung / kelancaran: DC53 / Ra0.4 Gamelan 4 set permukaan pangilon

Metode kontrol gaya aktif kanggo penet tablet: 4 set motor servo + Siemens PLC + layar tutul Weilun Tong 10 inci

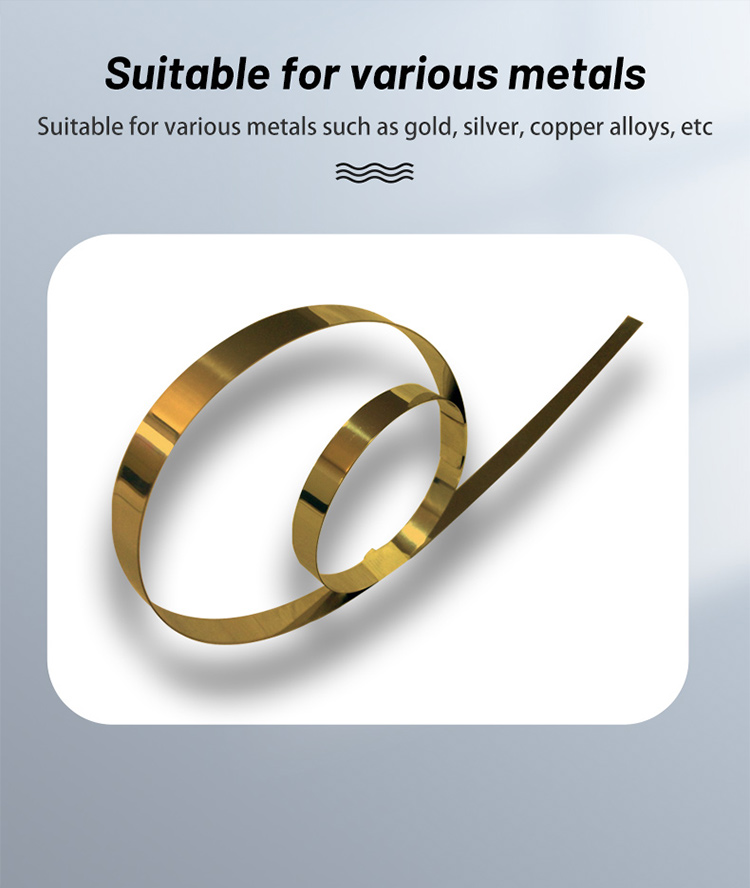

Ketebalan maksimum: 8mm

Ketebalan tablet paling tipis: 0,1 mm (emas)

Toleransi kekandelan produk rampung: plus utawa minus 0,01mm

Jembar komprèsi paling apik: ing 40mm

Akurasi celah rol pangaturan Servo: plus utawa minus 0.001mm

Kacepetan penet: 0-100 meter per menit (regulasi kacepetan motor servo)

Metode pangukuran produk rampung: pangukuran manual

Metode pelumasan bantalan: Pelumas padat

Cara pelumasan: pasokan lenga otomatis

Rolling mill dimensi: 1520 * 800 * 1630mm

Rolling mill bobot: kira-kira 750KG

Telpon: +86 17898439424

E-mail: sales@hasungmachinery.com.

WhatsApp: 0086 17898439424

Alamat: No.11, Jinyuan 1st Road, Komunitas Heao, Yuanshan Street, Distrik Longgang, ShenZhen, China 518115