Hasung ke Moetsi oa Mechini ea ho Qhibilihisa le ho Fokotsa Tšepe ea Bohlokoa ho tloha ka 2014.

Mochini oa ho lahla o Tsoelang Pele oa Hasung bakeng sa ho Etsa Pipe ea Rod Strip e nang le 20kg 30kg 50kg 100kg

Hang ha silevera ea khauta hlobolisa terata molamu o tsoelang pele ho lahla mochine bakeng sa mabenyane a qala 'marakeng, o ile a fumana maikutlo a nepahetseng ho tsoa ho bareki ba bangata, ba ileng ba re mofuta ona oa sehlahisoa o ka rarolla litlhoko tsa bona ka katleho.Ho feta moo, sehlahisoa se sebelisoa haholo ka Metal Casting.

Mochini o Tsoelang Pele oa ho Lahlela bakeng sa ho Etsa Pipe ea Rod Strip e nang le 20kg 30kg 50kg 100kg ha e bapisoa le lihlahisoa tse tšoanang 'marakeng, e na le melemo e ikhethang e ke keng ea lekanngoa mabapi le ts'ebetso, boleng, ponahalo, joalo-joalo,' me e thabela botumo bo botle 'marakeng.Hasung e akaretsa mefokolo ea lihlahisoa tse fetileng,' me e tsoela pele ho li ntlafatsa. Litlhaloso tsa Mochini o Tsoelang Pele oa ho Lahlela bakeng sa ho Etsa Pipe ea Strip ea 20kg 30kg 50kg 100kg e ka etsoa ho latela litlhoko tsa hau.

Lipotso tse botsoang khafetsa mabapi le mochini o qhibilihang

Ho na le mefuta e fapaneng le boholo ba silevera ea khauta strip wire tube rod continuous casting machine bakeng sa mabenyane ao bareki ba ka a rekang ho Hasung. silevera ea khauta hlobolisa terata molamu o tsoelang pele oa ho lahla mabenyane o nka bohlokoa bo boholo ho ntlafatso ea thekenoloji ts'ebetsong ea lipatlisiso le nts'etsopele. Hasung ke tharollo bakeng sa litlhoko tsohle tsa hau tsa ho reka. Re ka u fa litheko tseo u li hlokang le boleng bo u loketseng.

Likaroloana:

Ka likarolo tsa moruo, tse sebetsang le tse sebetsang hantle. Ntle le ts'ebetso e phahameng, e boetse e na le ts'enyehelo e tlase, ts'ebetso e tenyetsehang e tlisang phello e ntle ea ho lahlela.

Ts'ebetso eohle ea ho qhibiliha e sirelelitsoe ka khase ea argon ho thibela oxidation ea tšepe, mokhoa oa ho sotha o qobelloang.

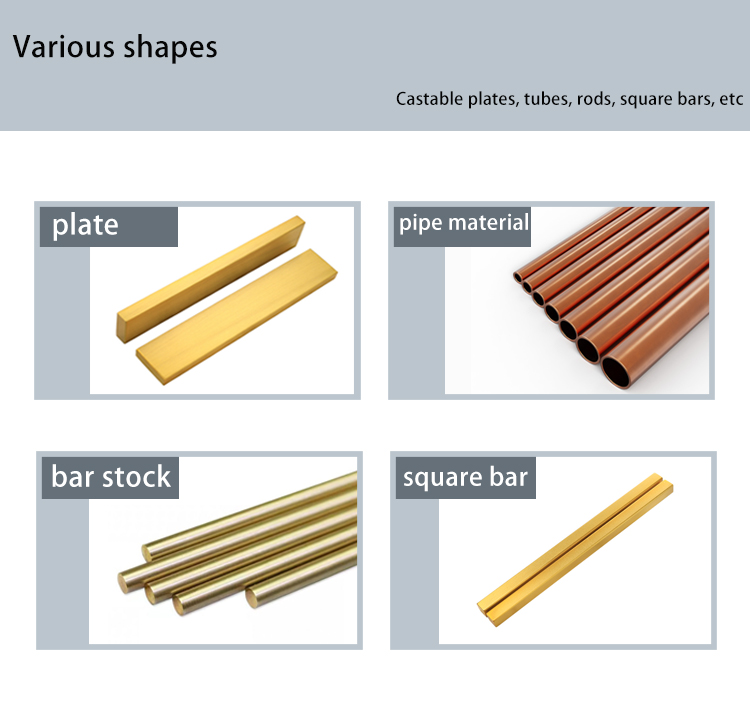

Ho qhibiliha ka potlako le ho lahla, ho loketse K-khauta, silevera, tube, selae, bar le libopeho tse ling.

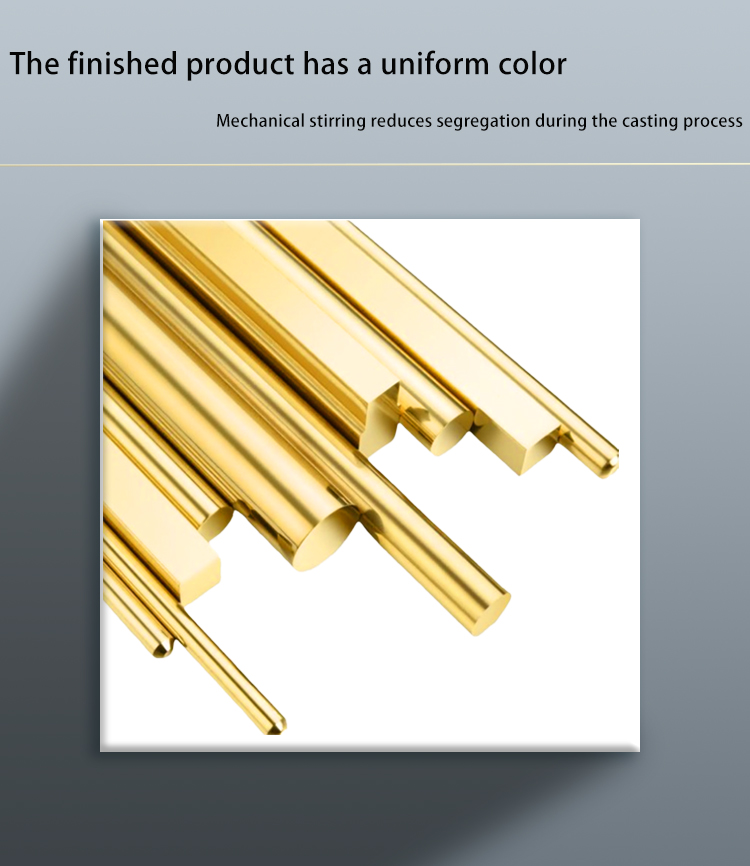

Ho futhumatsa ka mokhoa o ikhethileng o nang le ts'ebetso ea othomathike ho matlafatsa matla, esita le ho etsa lintho tsa mebala, bokhoni bo boholo ba ho lahla ho ntlafatsa katleho ea hau ea tlhahiso.

Taolo e nepahetseng ea mocheso ho etsa boemo bo phethahetseng ba ho lahla.

Sistimi e fapaneng ea ho iphumanela liphoso ho u fa mokhoa o bolokehileng oa ho lahla.

Hydraulic cutter ke khetho.

Ka taolo ea PC ea dijithale, e sebetsa ka bohlale.

Litlhaloso:

| Mohlala No. | HS-CC20 | HS-CC30 | HS-CC50 | HS-CC60 | HS-CC80 | HS-CC100 | HS-CC150 |

| Palo ea li-volts | 380V±20% 50/60HZ, karolo ea 3 | ||||||

| Matla | 30KW | 50KW | 60KW | 80KW | |||

| Bokhoni (Khauta) | 20kg | 30kg | 50kg | 60kg | 80kg | 100kg | 150kg |

| Lebelo la ho qhibiliha | 6-10 mets. | 10-15 mets. | 15-25 mets. | 10-15 mets. | 15-25 mets. | 20-30 mets. | 20-30 mets. |

| Lisebelisoa tsa tšepe | Khauta, khauta ea karat, silevera, koporo, lialloys | ||||||

| Max. Mocheso | 1500°C | ||||||

| Ho nepahala ha mocheso | ±1℃ | ||||||

| Lihlahisoa tsa ho lahlela | Mohala, molamu, hlobolisa, lakane, peipi, joalo-joalo. | ||||||

| Mofuta oa ho lahla | Khatiso e tsoelang pele | ||||||

| Khase e sa sebetseng | Naetrojene/Argon | ||||||

| Mokhoa oa ho pholisa | Mochini oa ho futhumatsa metsi / Metsi a mathang | ||||||

| Mokhoa oa ts'ebetso | Ts'ebetso ea senotlolo se le seng ho phethela ts'ebetso eohle, sistimi e se nang kelello ea POKA YOKE | ||||||

| Litekanyo | 890*1080*1800mm | ||||||

| Boima ba 'mele | Hoo e ka bang. 480kg | ||||||

Shenzhen Hasung Precious Metals Equipment Co., Ltd ke k'hamphani ea boenjiniere ea mechini e fumanehang ka boroa ho China, toropong e ntle le e holang ka potlako ho fetisisa moruong, Shenzhen. Khamphani ke moetapele oa theknoloji sebakeng sa ho futhumatsa le ho lahlela lisebelisoa tsa tšepe tsa bohlokoa le indasteri e ncha ea thepa. Tsebo ea rona e matla ea theknoloji ea vacuum casting e tsoela pele ho re thusa ho sebeletsa bareki ba indasteri ho lahlela tšepe e nang le alloyed e phahameng, vacuum e phahameng e hlokahalang platinum-rhodium alloy, khauta le silevera, joalo-joalo Sepheo sa rona ke ho haha mochine o mocha oa ho futhumatsa le oa ho lahla bakeng sa indasteri ea tšepe ea bohlokoa le indasteri ea mabenyane a khauta, ho fa bareki botšepehi bo phahameng ka ho fetisisa mesebetsing ea hau ea letsatsi le letsatsi le boleng bo phahameng ka ho fetisisa. Re amoheloa indastering joalo ka moetapele oa theknoloji. Seo re lokelang ho ba motlotlo ka sona ke vacuum ea rona le theknoloji e phahameng ea vacuum ke eona e molemo ka ho fetisisa Chaena. Thepa ea rona, e entsoeng Chaena, e entsoe ka likarolo tsa boleng bo holimo, e sebelisa likarolo tse tsebahalang lefatšeng ka bophara tse kang Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, joalo-joalo.

Hasung o sebelelitse ka boikhohomoso indasteri ea bohlokoa ea tšepe ea tšepe e nang le lisebelisoa tsa ho lahla khatello, mochini o tsoelang pele oa ho lahla, lisebelisoa tse phahameng tsa vacuum tse tsoelang pele, lisebelisoa tsa vacuum granulating, liipone tse qhibilihisang, mochini oa khauta oa silevera oa khauta, lisebelisoa tsa tšepe tsa atomizing, jj.

Lefapha la rona la R&D le lula le sebeletsa ho nts'etsapele mahlale a ho lahla le ho qhibilihisa ho lumellana le indasteri ea rona e lulang e fetoha bakeng sa indasteri ea New Materials, Aerospace, Meepo ea Khauta, Indasteri ea Metal Minting, Lilaboratori tsa Lipatlisiso, Potlako e Potlakileng, Mabenyane le Litšoantšo tsa Bonono. Re fana ka litharollo tsa tšepe tsa bohlokoa bakeng sa bareki. Re boloka molao-motheo oa "botšepehi, boleng, tšebelisano, win-win" filosofi ea khoebo, e ikemiselitseng ho theha lihlahisoa le litšebeletso tsa maemo a pele. Re lula re lumela hore theknoloji e fetola bokamoso.

Re sebetsa ka thata ho rala le ho nts'etsapele litharollo tsa ho qetela tsa tloaelo. Re ikitlaelletsa ho etsa hore mokhoa oa ho qetela o potlake le ho boloka chelete. Rea u amohela ho re etela.

Hasung e batla balekane le batseteli bakeng sa litšepe tsa bohlokoa ho nts'etsapele mahlale a mahlale a tlisang puseletso e ntle ho tsetelong.

P: Na u moetsi?

A: E, re moetsi oa pele oa lihlahisoa tsa boleng bo phahameng ka ho fetisisa bakeng sa tšepe ea bohlokoa e qhibilihisang le

lisebelisoa tsa ho lahla, haholo-holo bakeng sa vacuum ea theknoloji e phahameng le metjhini e phahameng ea vacuum. Rea u amohela ho etela fektheri ea rona e Shenzhen, China.

P: Tiisetso ea mochini oa hau e nka nako e kae?

A: Tiisetso ea lilemo tse peli.

P: Boleng ba mochini oa hau bo joang?

A: Ehlile ke boleng bo holimo ka ho fetisisa China indastering ena. Mechini eohle e sebelisa likarolo tsa mabitso a mabitso a tsebahalang ka ho fetesisa lefatšeng ka bophara. Ka moetso o moholo le boleng bo phahameng bo ka tšeptjoang.

P: Feme ea hau e hokae?

A: Re fumaneha Shenzhen, China.

P: Re ka etsa eng haeba re e-na le mathata ka mochine oa hau ha re ntse re sebelisa?

A: Ntlha ea pele, mechini ea rona ea ho futhumatsa ka induction le mechine ea ho lahla e na le boleng bo phahameng ka ho fetisisa indastering ena Chaena, bareki

hangata e ka e sebelisa lilemo tse fetang 6 ntle le mathata leha e le afe haeba e le tlas'a maemo a tloaelehileng a ho sebelisoa le tlhokomelo. Haeba u na le mathata, re tla hloka hore u re fe video ho hlalosa hore na bothata ke eng e le hore moenjiniere oa rona a tle a u ahlolele le ho u fumanela tharollo. Nakong ea tiisetso, re tla u romella likarolo tsa eona mahala hore u ka li nchafatsa. Ka mor'a nako ea tiisetso, re tla u fa likarolo tsa eona ka litšenyehelo tse tlase. Tšehetso ea nako e telele ea theknoloji e fanoa ka bolokolohi.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ke khamphani ea boenjiniere ba mechini e fumanehang ka boroa ho Chaena, motseng o motle le o holang ka potlako ka ho fetisisa moruong, Shenzhen. Khamphani ke moetapele oa theknoloji lefapheng la lisebelisoa tsa ho futhumatsa le ho lahla tšepe ea bohlokoa le indasteri ea thepa e ncha.

Tsebo ea rona e matla ea theknoloji ea ho lahla ka vacuum e re nolofalletsa ho sebeletsa bareki ba indasteri ho lahla tšepe e kopantsoeng ka bongata, motsoako oa platinum-rhodium o hlokahalang ka vacuum e ngata, khauta le silevera, jj.

Mohala: +86 17898439424

E-mail: sales@hasungmachinery.com.

WhatsApp: 0086 17898439424

Aterese: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115