Silver bar making machine 12kg gold bar forming machine Gold Bar Vacuum Casting Equipment

After multiple tests, it proves that utilizing technology contributes to high-efficiency manufacturing and ensuring the stability of 999,99 silver bar making machine smart gold bar forming machine.It has widespread uses in the application field(s) of Metal Casting Machinery and is totally worth the investment.

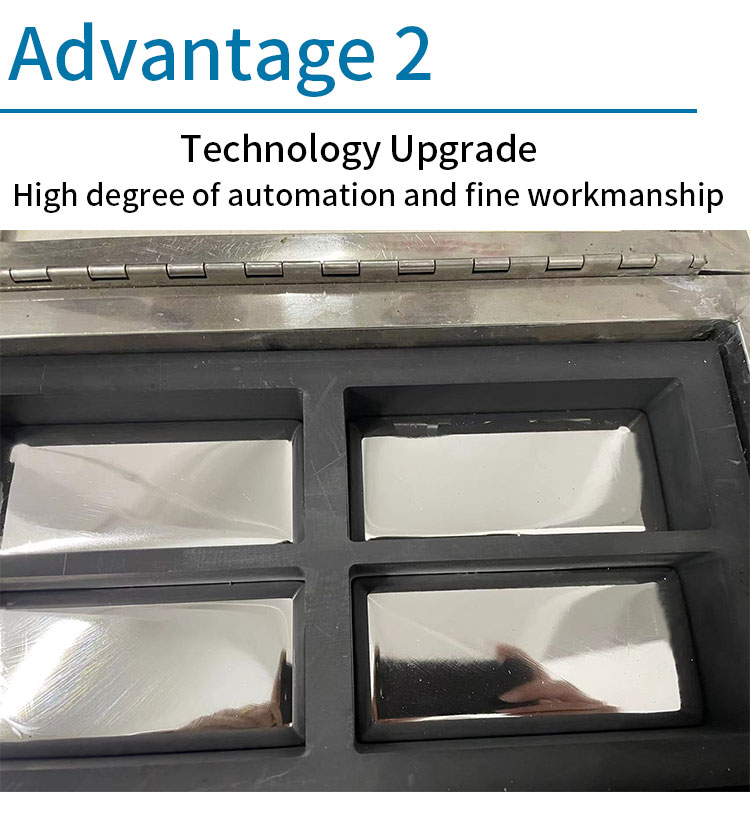

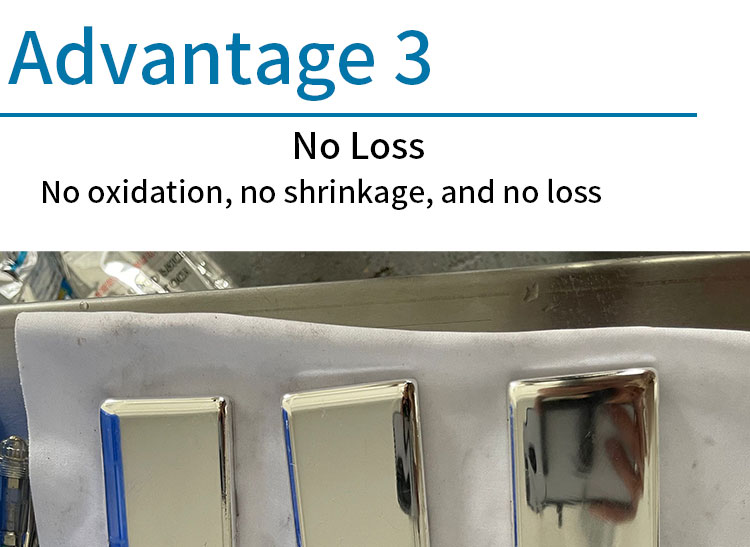

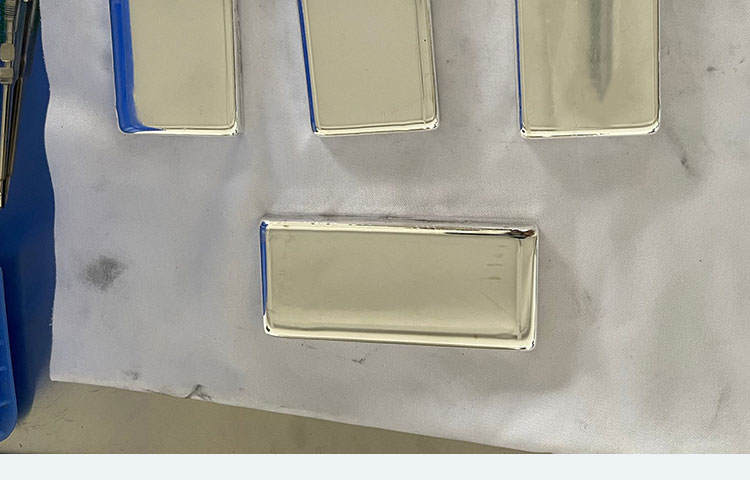

The introduction of this equipment completely replaces the traditional production process of gold and silver bars, completely solving the problems of easy shrinkage, water waves, oxidation, and unevenness of gold and silver. It uses full vacuum melting and rapid forming in one go, which can replace the current domestic gold bar production process, making the domestic gold bar casting technology reach the international leading level. The surface of the products produced by this machine is flat, smooth, non porous, and the loss is almost negligible, The use of fully automated control enables general workers to operate multiple machines, greatly saving production costs and making it an essential tool for major precious metal refineries.

Equipment introduction:

1. Adopt inert gas to protect the melting, prevent metal oxidation, power traction casting method, which can minimize the loss.

2. Cast high-density gold, K gold, silver and other precious metals in a short time, such as plate, round bar, square bar, round tube and special-shaped products.

3. The down-drawing method is adopted to control the internal sand holes in the profile to the lowest limit, and the finished product completely meets the requirements for deep processing.

4. Efficient and unique agitation induction heating, which enhances the power, uniformly dissolves the metal, increases the casting capacity, and increases the casting speed.

Silver bar making machine, gold bar forming casting machine

TECHNICAL SPECIFICATIONS:

1.Intelligent Vacuum Gold bar Casting System:

1). The most advanced full automatic casting system, One key can finish the entire casting process. Automatic close the cover–Automatic inert gas and vacuum-Automatic casting and cooling–Automatic open the cover–Take out the Shiny gold bar.

3. Using German IGBT induction heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving, and high work efficiency.

4. Melting under vacuum and inert gas protection atomophere which can prevent the oxidation of molten raw materials and without shrinkage, bubbles, etc. This equipment is suitable for the casting of high-purity gold silver materials.

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. This equipment uses Twaiwan PLC program control system or Siemens, Japan SMC/AirTec pneumatic components, Germany Omron, Schneider and Panasonic servo motor drive and other domestic and foreign brand components.

8. No oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

Introducing the Hasung Gold Bar Casting Machine - the ultimate solution for producing high quality gold and silver bars with ease and precision. This state-of-the-art machine is designed for automated operation and intelligent control, making it the perfect choice for businesses and individuals looking to streamline their gold and silver casting processes.

The Haxing gold ingot casting machine is designed with precision and reliability in mind, and is equipped with components from world-famous brands, such as Taiwan Weiwen, Siemens, Omron, Schneider, Shimao Electric, Airtec, etc. This ensures that all aspects of machine operation are of the highest quality, delivering consistent and reliable results every time it is used.

One of the outstanding features of the gold ingot casting machine is its automatic operation capability. This means users can simply set parameters and let the machine handle the rest, increasing efficiency and productivity. Whether you're casting gold or silver bars, this machine delivers superior results every time.

In addition to automatic operation, HaCheng gold ingot casting machine also has intelligent control functions. This enables users to precisely monitor and adjust the casting process, ensuring the final product meets its exact specifications. With intuitive controls and advanced technology, this machine puts the power of precision casting in your hands.

Hasung Gold Bar Casting Machine excels when it comes to the quality of gold bars produced. Due to its advanced design and high-quality components, the machine is able to produce rods of unrivaled quality. Whether you are a seasoned professional or new to the gold bar casting industry, you can trust that a Hasung gold bar casting machine will consistently deliver superior results.

For added peace of mind, Hasung gold bar casting machines come with a generous 2-year warranty. This demonstrates the manufacturer’s confidence in the durability and reliability of the machine, giving users confidence that their investment is protected.

All in all, the Hasung gold bar casting machine is a game changer for businesses and individuals involved in gold and silver bar production. With its automated operation, intelligent control and world-famous brand components, this machine has set a new standard in gold ingot casting technology. Whether you are looking to increase productivity, improve quality, or simply streamline your casting process, Hasung gold bar casting machines are the ideal solution. Invest in this machine and experience the difference it can make in your gold and silver casting operations.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115