Best Hasung - Manual Pouring Tilting Induction Melting Furnace with 1kg~10kg for Gold Silver

The use of highly advanced technologies contributes to the safe and efficient manufacturing of the product. At present, 1kg to 10kg Manual tilting type melting furnace Gold smelting Furnace tilting crucible furnace can be widely seen in the application scope(s) of Other Metal & Metallurgy Machines.

Hasung - 1kg to 10 kg Manual Tilting Pouring Melting Furnace Gold Smelting Furnace Tilting Crucible Melting Furnace compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of Hasung - 2kg to 1kg Manual Tilting Pouring Melting Furnace Gold Smelting Furnace Tilting Crucible Melting Furnace can be customized according to your needs.

ery.

The First-Class Level Quality and Technology for Precious Metals Equipment Manufacturer in China.

PRODUCT SPECIFICATIONS:

| Model No. | HS-TFQ2 | HS-TFQ3 | HS-TFQ4 | HS-TFQ5 | HS-TFQ6 | ||||

| Voltage | 380V, 50Hz, 3 phases | ||||||||

| Power | 15KW | 15KW | 20KW | ||||||

| Max Temp | 1600°C | ||||||||

| Capacity (Au) | 2kg | 3kg | 4kg | 5kg | 6kg | ||||

| Melting Time | 2-3 min. | 2-4 min. | 2-5 min. | 3-6 min. | |||||

| Max. temperature | 1600 degree celsius | ||||||||

| Application | Gold, K gold, silver, copper and other alloys | ||||||||

| Cooling method | Water chiller(sold separately) or Running water (water pump) | ||||||||

| Heating technology | Germany IGBT Induction heating | ||||||||

| Working time | 24 hours continuously working | ||||||||

| Dimensions | 90x48x100cm | ||||||||

| Weight | 90kg | 110kg | |||||||

Description:

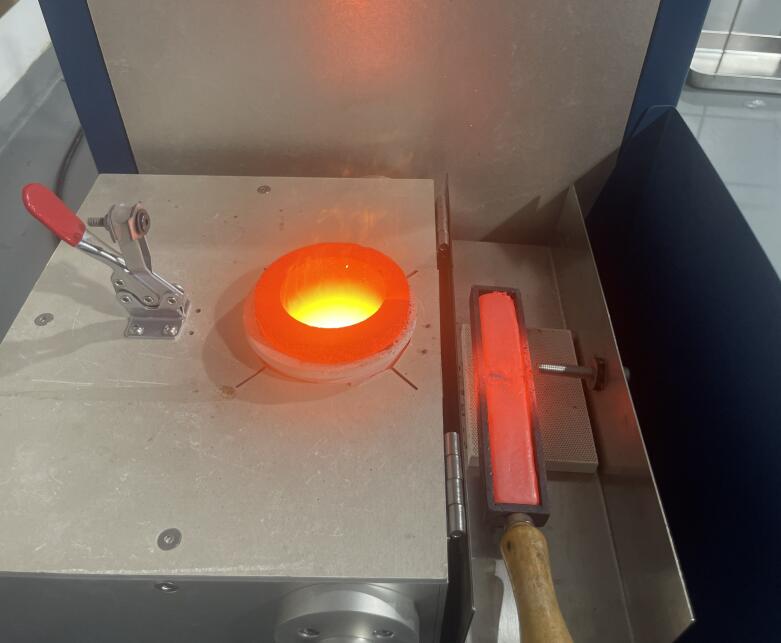

Tilting Melting Furnaces for melting large quantities of metal into ingots or bullions.

These machines are designed for melting large quantities, for example in the gold recycling factory for large capacity melting of 50kg or 100kg per batch.

Hasung TF series – tried and tested in foundries and precious metal refining groups.

Our tilting smelting furnaces are mainly used in two areas:-

1. for melting down large quantities of metal such as gold, silver or manufacturing metals industry like casting scraps, 15KW, 30KW, and maximum 60KW output and low-frequency tuning means fast melting which enjoys the best results from China – even for large volumes – and excellent through-mixing.

2. for casting large, heavy components after casting in other industries.

The TF20 to TF100 models, Depending on the model, the capacity ranges from a crucible volume of 20kg to 100kg for gold, mostly for precious metals manufacturing companies.

The MDQ series tilting furnaces are designed for both platinum and gold, all of metals such as platinum, palladium, stainless steel, gold, silver, copper, alloys etc, could be melted in one machine by changing crucibles only.This type furnaces are great for platinum melting, thus when pouring, machine keeps heating until you almost finish pouring, then pour shuts down automatically when almost finished.

FEATURES AT A GLANCE

Introducing small induction melting furnaces for smelting gold, silver and copper

Are you in the market for a reliable, efficient gold, silver or copper smelting solution? Our small induction melting furnace is your best choice. This cutting-edge device is designed to meet the needs of jewelers, metal fabricators and small manufacturers who require a melting solution that is fast, safe and easy to operate. With its new technology, fast melting capabilities and user-friendly design, our small induction melting furnace is the perfect choice for those looking to streamline their metal melting process.

Easy to operate

One of the outstanding features of our small induction melting furnaces is their ease of operation. The furnace is designed with user convenience in mind, featuring intuitive controls and a simple interface that makes it easy for operators to learn and use. Whether you're a seasoned professional or new to metalworking, you'll appreciate the simplicity of this furnace's operation.

New technology

Our small induction melting furnaces incorporate the latest advances in induction heating technology, ensuring efficient and consistent melting performance. Using induction heating, it has precise temperature control, uniform heating, and fast melting speed. It is an ideal choice for melting gold, silver, and copper. With this innovative technology at your fingertips, you can expect reliable and high-quality results every time. The heating generator is 100% designed and manufacturered by Hasung with assured quality.

Melts quickly

When it comes to metal melting, time is of the essence, and our small induction melting furnaces deliver speed. With its fast melting capability, you can significantly reduce the time it takes to melt metal, increasing productivity and meeting tight deadlines. Whether you are producing small batches or large batches, this furnace will help you get the job done quickly and efficiently.

Move easily

Portability is a key consideration for many businesses and our small induction melting furnaces are designed with this in mind. Its compact size and lightweight construction allow it to be easily moved and positioned within the workspace. Whether you need to relocate your furnace for cleaning, maintenance, or to accommodate changing production needs, you'll appreciate the convenience of its easy-to-move design.

Tilt pouring method

In addition to melting capabilities, our small induction melting furnaces feature a tilt pouring method for precise, controlled pouring of molten metal. This feature is especially valuable for applications that require precise casting, such as creating custom jewelry or intricate metal parts. With the ability to tilt and pour with ease, you can get the results you want effortlessly.

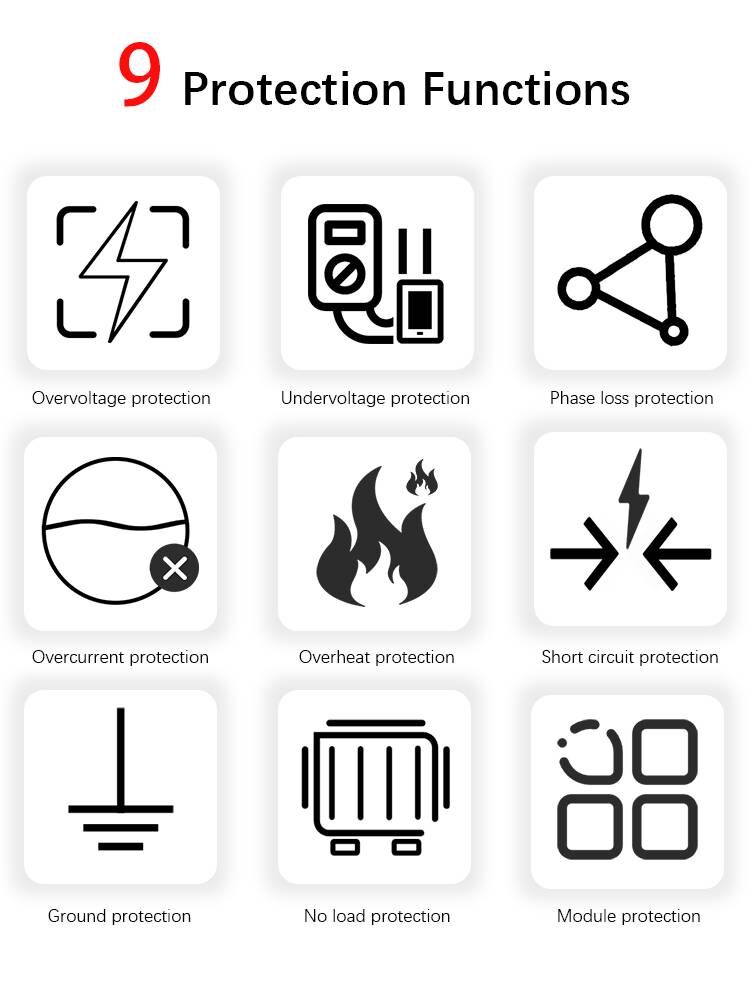

Safe for operators

Safety is paramount in any industrial environment and our small induction melting furnaces are designed with operator safety in mind. From its insulated construction to built-in safety features, this furnace provides a safe environment for melting operations. Operators can work with confidence knowing that the furnace is designed to minimize risk and ensure a safe working experience.

In summary, our small induction melting furnaces for gold, silver and copper melting are a versatile and reliable solution for businesses and craftsmen who require a high-performance melting furnace. With its simple operation, new technology, fast melting capabilities, easy-to-move design, tilt pouring method and focus on operator safety, the furnace is well-equipped to meet the needs of modern metalworking applications. Whether you are melting precious metals for jewelry making or processing copper for industrial use, our small induction melting furnaces are ideal for efficient, consistent results. Upgrade your metal melting capabilities today with our small induction melting furnace.

Company Advantages

Frequently Asked Questions about custom metal casting

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115