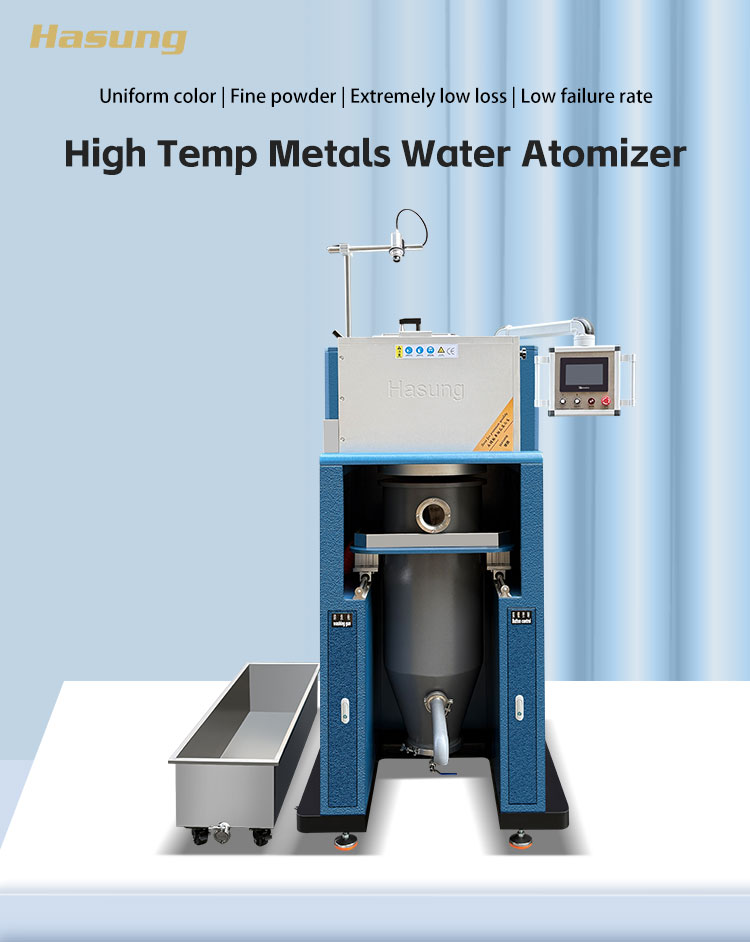

Hasung - High tempe metal water atomizer With 4KG For Gold/Silver/Copper/Platinum/Palladium

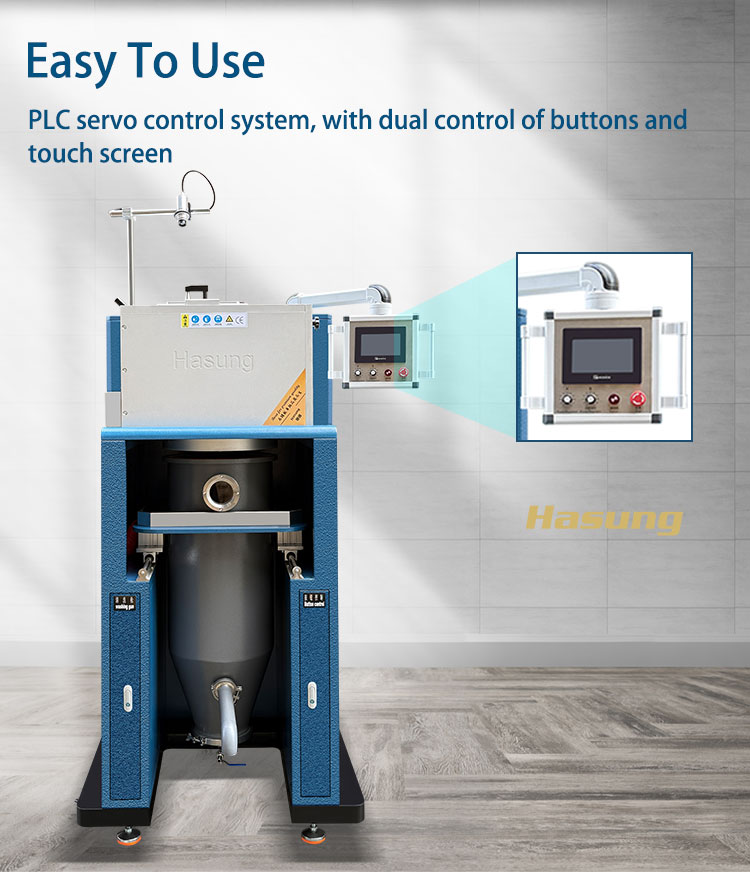

This equipment is used to produce high-quality and uniformly colored precious metal powders. Different models can be selected to complete powder production in a single cycle. The resulting powder is fine and uniform, with a maximum temperature of 2,200°C, suitable for producing platinum, palladium, and stainless steel powders. The process features short production time and integrates melting and powder manufacturing into one seamless operation. Inert gas protection during melting reduces metal loss and extends crucible service life. It is equipped with a dedicated automatic cooling water stirring system to prevent metal agglomeration and ensure finer powder formation. The device also includes a comprehensive self-diagnosis system and protection functions, ensuring low failure rates and longer equipment lifespan.

HS-MIP4

| Model | HS-MIP4 | HS-MIP5 | HS-MIP8 |

|---|---|---|---|

| Capacity | 4Kg | 5Kg | 8Kg |

| Voltage | 380V,50/60Hz | ||

| Power | 15KW*2 | ||

| Smelting time | 2-4Min | ||

| Maximum temperature | 2200℃ | ||

| Noble gas | Nitrogen/Argon | ||

| Cooling method | chiller | ||

| Cupola metal | Gold/Silver/Copper/Platinum/Palladium, etc | ||

| Device dimensions | 1020*1320*1680MM | ||

| Weight | About 580KG | ||

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115