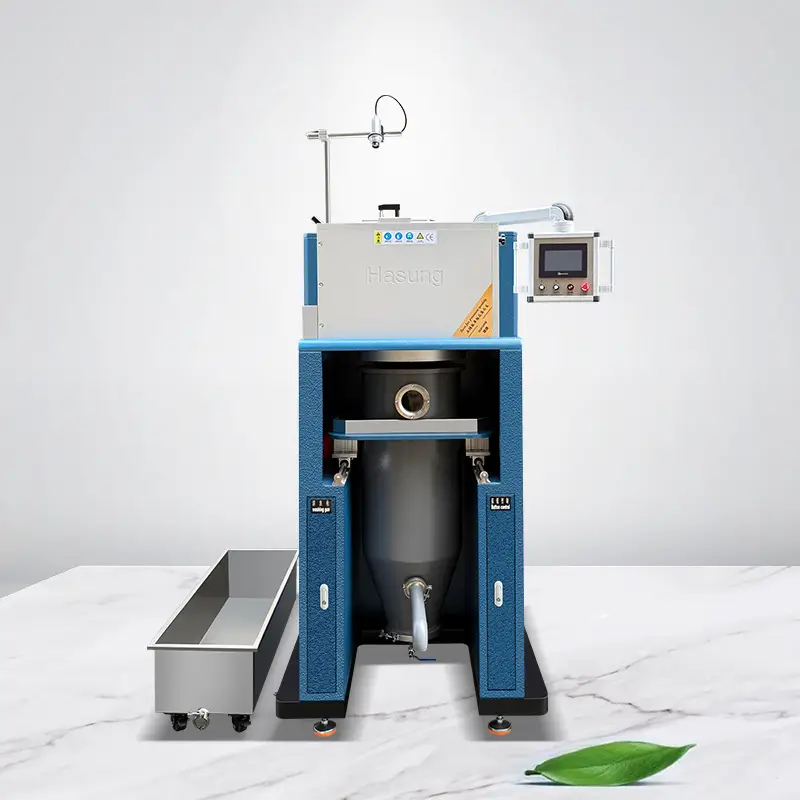

Qhov zoo tshaj plaws Kub Silver Copper Hlau Hmoov Atomization Tshuab 75-270 microns tuam txhab - Hasung

Cov thev naus laus zis yog qhov tseem ceeb rau peb txoj kev loj hlob thiab kev loj hlob. Raws li nws cov txiaj ntsig zoo ntawm cov hmoov hlau muaj txiaj ntsig ua cov cuab yeej Kub Nyiaj Tooj Tooj Plua Plav Atomizing Tshuab tau tshawb pom, nws cov peev txheej ntawm daim ntawv thov kuj tau nthuav dav heev. Nyob rau hauv daim teb (s) ntawm Lwm Cov Hlau & Metallurgy Machinery, nws muaj nqis heev.

Kub Silver Copper Hlau Hmoov Atomization Tshuab 75-270 microns piv nrog cov khoom zoo sib xws ntawm lub khw, nws muaj qhov zoo sib xws ntawm kev ua tau zoo, zoo, tsos, thiab lwm yam., thiab nyiam lub koob npe nrov hauv kev ua lag luam.Hasung summarizes qhov tsis xws ntawm cov khoom yav dhau los, thiab txuas ntxiv txhim kho lawv. Cov lus qhia tshwj xeeb ntawm Kub Nyiaj Tooj Tooj Hlau Hmoov Atomization Tshuab 75-270 microns tuaj yeem kho raws li koj xav tau.

Lub Hlau Powder Dej Atomizer Chav ua rau yuav luag txhua tus los tsim cov khoom me me ntawm cov khoom zoo, cov hmoov kheej kheej rau tib lub hom phiaj daim ntawv thov xws li roj atomized hmoov ntawm tus nqi pheej yig thiab tsis muaj cov txheej txheem nyuaj.

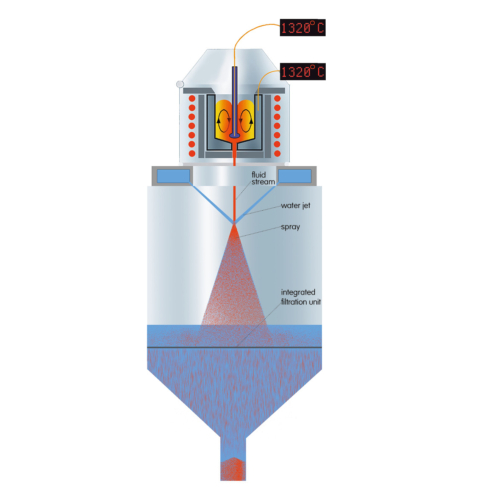

Txheej txheem cej luam ntawm dej atomizer

MGA series muaj nyob hauv ntau qhov sib txawv.

Lub melting thiab alloying ntawm cov khoom nyob rau hauv lub crucible yuav siv sij hawm qhov chaw nrog ib tug indirect induction system (xws li graphite crucible) los yog ib tug ncaj induction system rau high kub (ceramic crucible). Nrog rau ntau hom kev xaiv, lub tshuab tuaj yeem nruab raws li cov kev xav tau tshwj xeeb.

Feedstock tuaj yeem ua tau ntau dua lossis tsawg dua txhua yam - tsis yog ua ntej-alloyed hlau lossis bar, tsuav nws tuaj yeem nkag mus rau hauv crucible.

Tsis xav tau kev tsim cov hlau tsis yooj yim thiab kim tshaj li cov khoom siv rau cov khoom siv atomizing, uas yog siv sijhawm ntev thiab yuav tsum muaj kev tsim kho ntxiv xws li cov tshuab nrum nruam, lub rooj zaum kos duab thiab lwm yam.

Tsis tshua muaj spherical hmoov

tsis muaj satellites rau lub siab tshaj plaws hmoov fluidity thiab bulk ntom. Nws tuaj yeem siv tau zoo rau cov ntaub ntawv tsis yog hlau (qee yam yuav tsum muaj fluidity).

Qhov zoo ntawm crucible-raws li ultrasonic atomizing txoj cai

Kev tiv thaiv ntawm cov khoom poob thiab tsis raug ntawm alloy chemistry

vim muaj kev tswj xyuas qhov kub ntawm qhov kub ntawm qhov hluav taws xob los ntawm kev siv hluav taws xob hauv hluav taws xob, thaum evaporation ntawm cov khoom xyaw xws li Zn, Cr thiab lwm yam yog ib qho teeb meem tshwm sim thaum lub sij hawm plasma-pab atomization.

Muaj peev xwm tsim tau tus kheej alloy muaj pes tsawg leeg hauv Atomizer's crucible-based melting system.

Alloying nrog ib tug zoo nplawm / sib tov nyhuv vim muaj zog nruab nrab zaus induction generator nrog ib txhij high cua kub efficiency. Melting nyob rau hauv lub tshuab nqus tsev los yog inert gas cua thiab atomizing nyob rau hauv inert gas cua.

Hlau hmoov atomizer muaj xws li:

1.Smelting Chamber 1 teeb;

2. Atomization system 1 teeb;

3. Tswj System 1 teeb;

4. Kev Ua Haujlwm Platform 1 teeb;

5. Lub tshuab nqus dej siab 1 teeb;

6. Dej Cia System 1 teeb;

7. Kev sib cais 1 teeb;

8.1 teeb ntawm Crucible.

Qauv No. | HS-GMI 10 | HS-GMI50 |

Qhov hluav taws xob | 380V 3 theem, 50/60Hz | |

Total Power Supply | 100KW | 120KW |

Max Temp | 1450°C | |

Lub sij hawm yaj | ||

Hmoov qhov ntau thiab tsawg | 75-270 microns (kho.) | |

Temp raug | ±1°C | |

Muaj peev xwm | 10kg (kub) | 30kg (kub) |

| Dej siab | 0.2-0.4Mpa | |

| Dej temp. | 18-22°C | |

| Atomizing disk | Txais yuav imported lub teb chaws Yelemees thawj Cheebtsam thiab technology | |

Lub tshuab nqus tsev twj | Lub tshuab nqus tsev degree siab | |

Daim ntawv thov | Kub, nyiaj, tooj liab, alloys | |

Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | |

| Lub twj tso kua mis siab | Kov lub txim txhaum cai | |

Induction Generator Tswj System | Mitsubishi PLC + Tib neeg-tshuab interface ntse tswj qhov system | |

Tiv thaiv Gas | Nitrogen / Argon | |

Hom cua txias | Dej chiller (muag nyias) | |

Qhov ntev | 3400 * 3200 * 3880mm | |

Qhov hnyav | kwv yees. 2800kg ib | |

Kev piav qhia

Kev txawj ntse hlau atomization hmoov ua cov cuab yeej yog tsim thiab tsim los ntawm Shenzhen Hasung Precious Metals Equipment Co., Ltd, tshwj xeeb uas tsim los tsim cov hlau me me hmoov batches flexibly thiab economically. Tsob ntoo loj-loj ntau lawm tsis tuaj yeem muab qhov txiaj ntsig kev lag luam no. Alloys uas nquag hloov thaum lub sij hawm tsim khoom yuav tsum tau purity siab kom tsis txhob kis kab mob. Tshwj xeeb tshaj yog nyob rau hauv aviation, aerospace los yog precious hlau hmoov daim ntaub ntawv, me me ntawm ntau yam hmoov yog feem ntau yuav tsum tau, thiab muaj feem ntau yog tshiab alloy hmoov uas tsis muaj nyob rau hauv lub lag luam. Tshwj xeeb tshaj yog ceev-tsim daim ntaub ntawv xws li SLM thiab MIM xav tau ntau thiab ntau tshwj xeeb hlau hmoov.

Cov qauv:

Q: Koj puas yog cov chaw tsim khoom?

A: Yog lawm, peb yog cov chaw tsim khoom qub ntawm cov khoom lag luam zoo tshaj plaws rau cov khoom siv hlau smelting thiab casting, tshwj xeeb tshaj yog rau cov tshuab nqus tsev siab thiab cov tshuab nqus tsev siab. Txais tos tuaj xyuas peb lub Hoobkas hauv Shenzhen, Suav.

Q: Koj lub tshuab warranty ntev npaum li cas?

A: Ob xyoos warranty.

Q: Koj lub tshuab zoo li cas?

A: Tseeb tiag nws yog qhov zoo tshaj plaws hauv Suav teb hauv kev lag luam no. Txhua lub tshuab siv qhov zoo tshaj plaws ntiaj teb nto moo hom npe qhov chaw. Nrog kev ua haujlwm zoo thiab txhim khu kev qha zoo tshaj plaws. Q: Koj lub Hoobkas nyob qhov twg? A: Peb nyob hauv Shenzhen, Suav.

Q: Peb tuaj yeem ua li cas yog tias peb muaj teeb meem nrog koj lub tshuab thaum siv?

A: Ua ntej, peb lub tshuab cua sov induction thiab cov tshuab casting yog qhov zoo tshaj plaws hauv kev lag luam hauv Suav teb, cov neeg siv khoom feem ntau tuaj yeem siv nws rau ntau tshaj 6 xyoo yam tsis muaj teeb meem yog tias nws nyob rau hauv ib txwm siv thiab tu. Yog tias koj muaj teeb meem, peb xav kom koj muab peb cov vis dis aus los piav qhia qhov teeb meem yog li cas peb tus engineer yuav txiav txim siab thiab nrhiav kev daws rau koj. Tsis pub dhau lub sijhawm lav, peb yuav xa cov khoom dawb rau koj los hloov. Tom qab lub sijhawm lav, peb yuav muab cov khoom rau koj ntawm tus nqi pheej yig. Lub neej ntev kev txhawb nqa muaj kev ywj pheej.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115