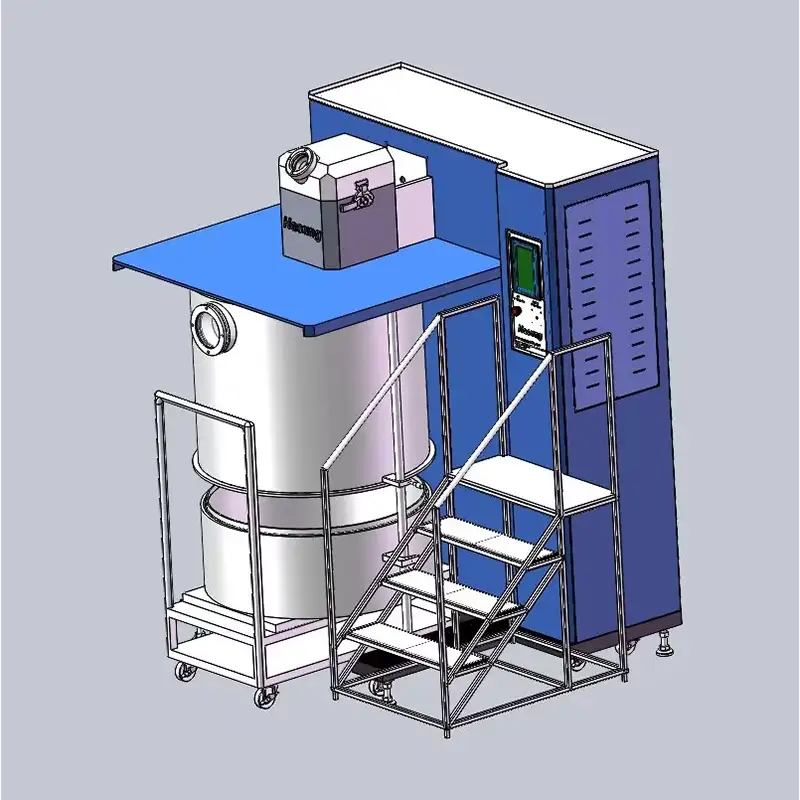

Customized Hasung Kub Casting Kub Refining Tshuab Kub Flakes Ua Tshuab Tuam Tshoj | Hasung

Hasung tuaj yeem xa Hasung bullion casting kub refining tshuab Kub Refining khoom Kub Flakes Ua Tshuab qhov zoo tshaj plaws ntawm tus nqi qis.Peb ib txwm xyuas kom cov neeg yuav khoom tau txais yam lawv xav tau.

Hasung Kub Casting Kub Refining Tshuab Kub Flakes Ua Tshuab piv nrog cov khoom zoo sib xws ntawm kev ua lag luam, nws muaj qhov zoo sib xws ntawm kev ua tau zoo, zoo, zoo li, thiab lwm yam, thiab nyiam lub koob npe nrov hauv kev ua lag luam.Hasung piav qhia txog qhov tsis xws ntawm cov khoom dhau los, thiab txhim kho lawv tsis tu ncua. Cov specifications ntawm Hasung Kub Casting Kub Refining Tshuab Kub Flakes Ua Tshuab tuaj yeem kho raws li koj xav tau.

Technical Specification

| Qauv No. | HJ-MS5 | HJ-MS8 | HJ-MS30 | HJ-MS50 |

| Qhov hluav taws xob | 380V, 50Hz, 3 theem | 380V, 50Hz, 3 theem | 380V, 50Hz, 3 theem | 380V, 50Hz, 3 theem |

| Hwj chim | 10KW | 15KW | 30KW | 30KW/50KW |

| Max kub | 1500 ℃ | 1500 ℃ | 1500 ℃ | 1500 ℃ |

| Lub sijhawm yaj | 2-3 feeb. | 2-5 feeb. | 4-6 feeb. | 10-15 feeb. |

| Kev tiv thaiv roj | Argon / Nitrogen | |||

| Daim ntawv thov | Kub, nyiaj, tooj liab Alloys (Platinum alloys, palladium alloys) | |||

| Txoj kev ua kom txias | Dej chiller / dej ntws | |||

| Flasks thickness | 0.1-0.5 hli | |||

| Tswj qhov system | Taiwan Weinview / Siemens PLC kov vaj huam sib luag | |||

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | |||

| Qhov ntev | 1120x1080x1750mm | 1260x1060x1920mm | ||

| 280kg ua | 400 kg | |||

Kub flakes

Platinum flakes

Title: Qhov tseem ceeb ntawm kub alloy flakes nyob rau hauv cov txheej txheem refining

Kub refining yog ib qho txheej txheem zoo tib yam uas yuav tsum tau ua kom raug thiab ua tib zoo saib kom meej. Ua ntej qhov tseeb refining yuav pib, cov kub tsis huv yuav tsum tau hloov mus rau hauv flakes los yog hmoov. Qhov no yog qhov uas sheet hlau ua tshuab tuaj ua si. Nyob rau hauv no blog, peb yuav delve rau hauv qhov tseem ceeb ntawm kub alloy flakes nyob rau hauv cov txheej txheem refining thiab lub luag hauj lwm ntawm hlau flake ua tshuab nyob rau hauv ua kom tiav cov kauj ruam tseem ceeb no.

Kub alloys yog kev sib txuas ntawm kub thiab lwm yam hlau, feem ntau muaj impurities uas yuav tsum tau muab tshem tawm los ntawm cov txheej txheem refining. Ua ntej refining, txawm li cas los xij, cov kub tsis huv yuav tsum tau hloov mus rau hauv daim ntawv uas muaj txiaj ntsig zoo rau cov txheej txheem refining. Qhov no yog qhov uas tsim cov flakes lossis hmoov ua qhov tseem ceeb.

Cov txheej txheem ntawm tig kub alloy rau hauv flakes los yog hmoov yog ib kauj ruam tseem ceeb hauv cov txheej txheem refining. Nws koom nrog kev siv cov tshuab tshwj xeeb los hloov cov khoom kub alloy rau hauv daim ntawv xav tau. Cov flakes los yog hmoov no muaj thaj tsam loj dua, uas ua rau nws yooj yim dua rau kev ua kom cov tshuaj zoo rau kev cuam tshuam nrog impurities thiab tshem tawm lawv zoo.

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev siv lub tshuab hlau flakes yog lub peev xwm los tsim cov flakes zoo ib yam thiab tsis sib xws los yog hmoov. Qhov kev sib txuam no yog qhov tseem ceeb los xyuas kom meej tias cov txheej txheem kho kom zoo ua tau zoo thiab ua tau zoo. Lub tshuab muaj peev xwm ua tsis tu ncua ua cov hlau alloys hauv cov duab uas xav tau, uas yog ib qho tseem ceeb heev kom tau txais cov khoom zoo zoo refined kub.

Tsis tas li ntawd, kev tsim cov flakes los yog hmoov kuj pab txhawb kev sib xyaw ua ke ntawm kub alloys nrog cov tshuaj ua kom zoo. Qhov loj dua qhov chaw ntawm cov flakes tso cai rau kev sib cuam tshuam zoo ntawm cov kub thiab tshuaj, ua kom lub hom phiaj zoo thiab tshem tawm cov impurities thaum lub sij hawm ua kom zoo dua.

Ntxiv nrog rau kev ua kom yooj yim rau cov txheej txheem refining, kev tsim cov flakes los yog hmoov kuj ua kom yooj yim rau kev ntsuas kub ntawm cov alloys. Lub uniformity ntawm cov flakes xyuas kom meej tias qhov tseeb ntawm cov kub yog siv nyob rau hauv cov txheej txheem refining, uas ua rau cov ntsiab lus tseeb thiab raug.

Tsis tas li ntawd, kev siv cov hlau flake ua tshuab kuj ua rau muaj kev nyab xeeb tag nrho ntawm cov txheej txheem refining. Los ntawm kev tsim cov flakes lossis hmoov, qhov kev pheej hmoo ntawm kev raug tshuaj lom neeg raug txo kom tsawg vim tias thaj chaw loj dua tso cai rau kev tswj kom zoo dua qub thiab kev tswj xyuas thaum lub sijhawm ua kom zoo dua.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov zoo ntawm cov flakes los yog hmoov tsim yog qhov tseem ceeb rau kev ua tiav ntawm cov txheej txheem refining. Yog li ntawd, nws yog ib qho tseem ceeb los xaiv ib tug txhim khu kev qha, high-zoo sheet hlau ua tshuab. Lub tshuab yuav tsum muaj peev xwm tsim tau zoo ib yam, zoo ib yam thiab zoo flakes los yog hmoov los xyuas kom meej cov kev ua tau zoo ntawm cov txheej txheem refining.

Hauv cov ntsiab lus, kev tsim cov flakes los yog hmoov los ntawm kub alloys yog ib kauj ruam tseem ceeb hauv cov txheej txheem refining. Kev siv cov hlau flake ua tshuab ua lub luag haujlwm tseem ceeb hauv kev ua tiav cov kauj ruam tseem ceeb no, pab txhawb kev ua tau zoo, raug thiab kev nyab xeeb ntawm cov txheej txheem refining. Los ntawm kev tsim cov khaub ncaws zoo, zoo flakes lossis hmoov, lub tshuab pab tshem tawm impurities zoo thiab tsim cov kub zoo tshaj plaws.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115