Hasung ƙwararren masani ne kan sarrafa injinan siminti da narke ƙarfe masu daraja tun daga shekarar 2014.

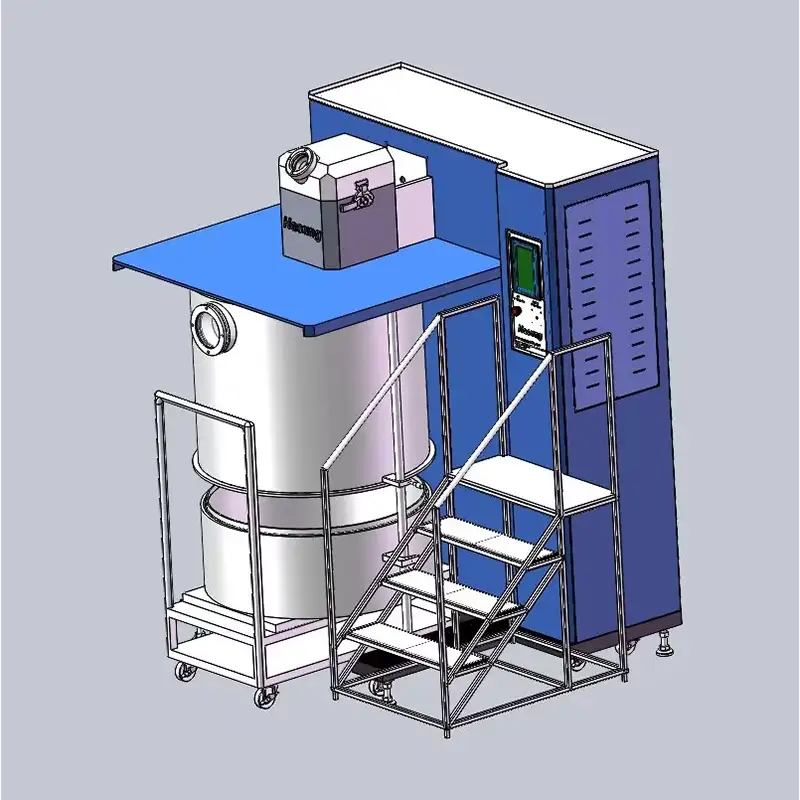

Injin Hasung Gold Casting Gold Refining Machine Masu Kera Injin Zinare Flakes Na Zinare Daga China | Hasung

Hasung zai iya isar da na'ura mai gyaran gwal na Hasung bullion Zinare kayan aikin gwal na Zinare Gilashin Gilashin Gilashin Gina Mafi kyawun inganci a cikin ƙananan farashi.A koyaushe muna tabbatar da cewa masu siye suna samun abin da suke buƙata.

Hasung Gold Casting Gold Refining Machine Gold Flakes Making Machine idan aka kwatanta da irin waɗannan samfuran a kasuwa, yana da fa'idodi maras misaltuwa dangane da aiki, inganci, bayyanar da sauransu, kuma yana jin daɗin kyakkyawan suna a kasuwa.Hasung yana taƙaita lahani na samfuran da suka gabata, kuma yana ci gaba da inganta su. Ƙayyadaddun ƙayyadaddun na'ura na Hasung Gold Casting Gold Refining Machine Gold Flakes Yin Injin ana iya keɓance shi gwargwadon bukatun ku.

Ƙayyadaddun Fasaha

| Model No. | HJ-MS5 | HJ-MS8 | HJ-MS30 | HJ-MS50 |

| Wutar lantarki | 380V, 50Hz, 3 matakai | 380V, 50Hz, 3 matakai | 380V, 50Hz, 3 matakai | 380V, 50Hz, 3 matakai |

| Ƙarfi | 10KW | 15KW | 30KW | 30KW/50KW |

| Matsakaicin zafin jiki | 1500 ℃ | 1500 ℃ | 1500 ℃ | 1500 ℃ |

| Lokacin narkewa | 2-3 min. | 2-5 min. | 4-6 min. | 10-15 mm. |

| Gas mai kariya | Argon / Nitrogen | |||

| Aikace-aikace | Gold, Azurfa, Tagulla Alloys (Platinum alloys, palladium alloys) | |||

| Hanyar sanyaya | Ruwa mai sanyi/Ruwa mai gudana | |||

| Kaurin flasks | 0.1-0.5mm | |||

| Tsarin sarrafawa | Taiwan Weinview/Siemens PLC touch Panel | |||

| Hanyar aiki | Aiki mai maɓalli ɗaya don kammala gabaɗayan tsari, POKA YOKE tsarin mara wawa | |||

| Girma | 1120x1080x1750mm | 1260x1060x1920mm | ||

| 280kg | 400kg | |||

Gwal gwal

Platinum flakes

Take: Muhimmancin gwal gwal a cikin aikin tacewa

Gyaran gwal wani tsari ne mai mahimmanci wanda ke buƙatar daidaito da kulawa ga daki-daki. Kafin a fara aikin tacewa na ainihi, zinaren da ba shi da kyau dole ne a juye shi ya zama flakes ko foda. Anan ne injunan kera karafa ke shiga wasa. A cikin wannan rukunin yanar gizon, za mu yi la'akari da mahimmancin gwal gwal a cikin aikin tacewa da kuma rawar da injinan ƙera ƙarfe ke da shi wajen cimma wannan muhimmin mataki.

Gilashin gwal ɗin haɗe-haɗe ne na zinari da sauran ƙarfe, galibi suna ɗauke da ƙazanta waɗanda ke buƙatar cirewa ta hanyar aikin tacewa. Kafin tacewa, duk da haka, zinare maras kyau yana buƙatar canza shi zuwa wani nau'i mai fa'ida ga aikin tacewa. Wannan shine inda samar da flakes ko foda ya zama mahimmanci.

Tsarin juya gwal ɗin gwal zuwa flakes ko foda mataki ne mai mahimmanci a cikin aikin tacewa. Ya ƙunshi yin amfani da injuna na musamman don canza ƙaƙƙarfan gwal ɗin gwal zuwa sigar da ake so. Wadannan flakes ko foda suna da wurin da ya fi girma, wanda ke sauƙaƙa don tace sinadarai don hulɗa tare da ƙazanta da kuma cire su yadda ya kamata.

Ɗaya daga cikin manyan fa'idodin yin amfani da na'ura mai ƙera ƙwalƙwalwar ƙarfe shine ikon samar da daidaito da daidaiton flakes ko foda. Wannan daidaituwa yana da mahimmanci don tabbatar da cewa aikin tacewa ya ci gaba da inganci da inganci. Na'urar tana iya ci gaba da samar da gwal ɗin gwal a cikin siffar da ake so, wanda ke da mahimmanci don samun ingantaccen gwal mai inganci.

Bugu da ƙari, samar da flakes ko foda kuma yana sauƙaƙe haɗakar da kayan gwal na gwal tare da sinadarai masu tacewa. Mafi girman yanki na flakes yana ba da damar kyakkyawar hulɗa tsakanin zinari da sinadarai, tabbatar da ingantacciyar manufa da kawar da ƙazanta yayin aikin tacewa.

Baya ga sauƙaƙe aikin tacewa, samar da flakes ko foda kuma yana sauƙaƙe madaidaicin ma'aunin gwal. Daidaitaccen nau'i na flakes yana tabbatar da cewa ana amfani da ainihin adadin zinari a cikin tsarin tsaftacewa, yana haifar da daidaitattun sakamako masu kyau.

Bugu da kari, yin amfani da na'urorin kera flake na ƙarfe kuma yana ba da gudummawa ga amincin tsarin aikin tacewa gabaɗaya. Ta hanyar samar da flakes ko foda, ana rage haɗarin fallasa ga sinadarai masu haɗari saboda babban yanki yana ba da damar ingantaccen tsari da sarrafawa yayin aikin tacewa.

Yana da mahimmanci a lura cewa ingancin flakes ko foda da aka samar yana da mahimmanci ga nasarar aikin tsaftacewa. Don haka, yana da mahimmanci a zaɓi ingantacciyar ingantacciyar na'ura mai ƙira. Ya kamata na'urar ta iya samar da daidaito, daidaito da kuma ingancin flakes ko foda don tabbatar da tasiri na tsarin tsaftacewa.

A taƙaice, samar da flakes ko foda daga gwal ɗin gwal mataki ne mai mahimmanci a cikin aikin tacewa. Yin amfani da na'urori masu yin gyare-gyare na karfe yana taka muhimmiyar rawa wajen cimma wannan muhimmin mataki, yana taimakawa wajen haɓaka inganci, daidaito da amincin tsarin tsaftacewa. Ta hanyar samar da uniform, flakes ko foda masu inganci, injin yana taimakawa yadda yakamata ya cire datti kuma ya samar da ingantaccen gwal mai inganci.

Lambar waya: +86 17898439424

Imel: sales@hasungmachinery.comda

WhatsApp: 0086 17898439424

Adireshi: No.11, Titin 1st Jinyuan, Al'ummar Heao, Titin Yuanshan, Gundumar Longgang, ShenZhen, China 518115