UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

Umshini Wokucwenga Wegolide We-Hasung Owenziwe Ngegolide Abakhiqizi Begolide Abakhiqizi Abasuka E-China | I-Hasung

I-Hasung ingaletha umshini wokucwenga wegolide we-Hasung bullion Impahla yokucwenga Igolide Imishini Yokwenza Izingcezu Zegolide ikhwalithi engcono kakhulu ngamanani aphansi.Sihlala siqinisekisa ukuthi abathengi bathola abakudingayo.

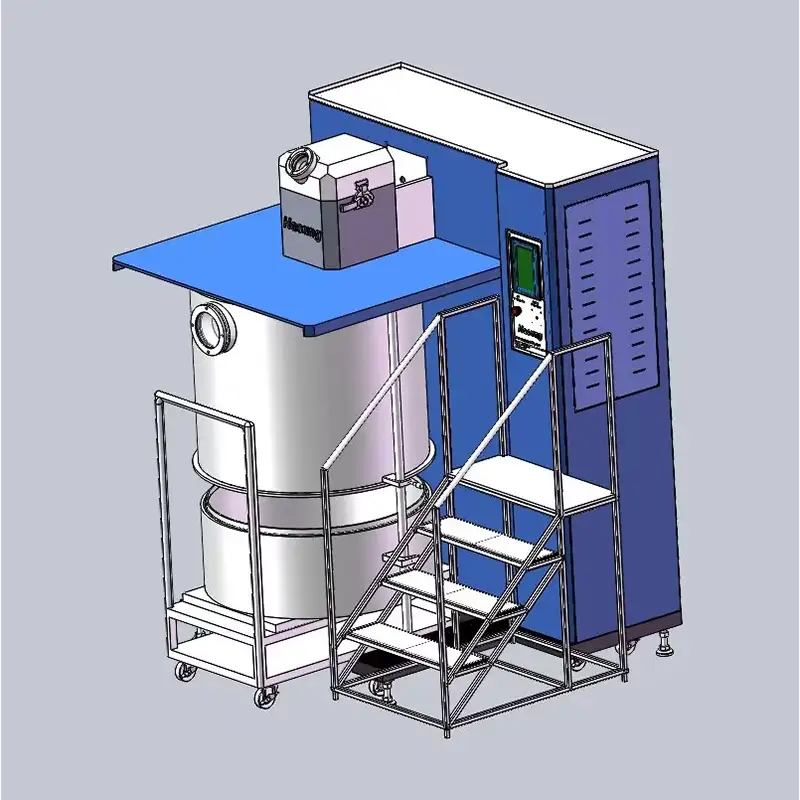

Umshini Wokwenza Igolide Wokucwenga I-Hasung Umshini Wokwenza Ama-Flakes Egolide uma uqhathaniswa nemikhiqizo efanayo emakethe, unezinzuzo ezivelele ezingenakuqhathaniswa ngokusebenza, ikhwalithi, ukubukeka, njll., futhi ujabulela idumela elihle emakethe.I-Hasung ifingqa iziphambeko zemikhiqizo edlule, futhi iqhubeka ithuthukisa. Imininingwane Yomshini Wokucwenga we-Hasung Gold Casting Gold Refining Umshini Wokwenza Ama-Flakes Egolide ungenziwa ngokwezifiso ngokuya ngezidingo zakho.

Ukucaciswa Kwezobuchwepheshe

| Imodeli No. | HJ-MS5 | HJ-MS8 | HJ-MS30 | HJ-MS50 |

| Amandla kagesi | 380V, 50Hz, 3 izigaba | 380V, 50Hz, 3 izigaba | 380V, 50Hz, 3 izigaba | 380V, 50Hz, 3 izigaba |

| Amandla | 10KW | 15KW | 30KW | 30KW/50KW |

| Izinga lokushisa eliphezulu | 1500 ℃ | 1500 ℃ | 1500 ℃ | 1500 ℃ |

| Isikhathi sokuncibilika | 2-3 amaminithi. | 2-5 imiz. | 4-6 imiz. | 10-15 mim. |

| Igesi yokuzivikela | I-Argon/Nitrogen | |||

| Isicelo | Igolide, isiliva, i-alloys yethusi (ama-alloys ePlatinum, ama-palladium alloys) | |||

| Indlela yokupholisa | I-water chiller/Amanzi agijimayo | |||

| Ukuqina kwama-flasks | 0.1-0.5mm | |||

| Isistimu yokulawula | Iphaneli yokuthinta ye-Taiwan Weinview/Siemens PLC | |||

| Indlela yokusebenza | Ukusebenza kokhiye owodwa ukuqedela yonke inqubo, uhlelo lwe-POKA YOKE olungenangqondo | |||

| Ubukhulu | 1120x1080x1750mm | 1260x1060x1920mm | ||

| 280kg | 400kg | |||

Ama-flakes egolide

Amaqabunga ePlatinum

Isihloko: Ukubaluleka kwama-alloy flakes egolide ohlelweni lokucwenga

Ukucwenga igolide kuyinqubo ecophelelayo edinga ukunemba nokunaka imininingwane. Ngaphambi kokuba umsebenzi wangempela wokucwenga uqale, igolide elingcolile kufanele liguqulwe libe amaflakes noma impushana. Yilapho imishini yokwenza amashidi ensimbi iqala ukusebenza khona. Kule bhulogi, sizocubungula ukubaluleka kwama-alloy flakes egolide ohlelweni lokucwenga kanye nendima yemishini yokwenza i-metal flake ekufezeni lesi sinyathelo esibucayi.

Ama-alloys egolide ayinhlanganisela yegolide nezinye izinsimbi, ngokuvamile aqukethe ukungcola okudingeka kususwe ngenqubo yokucwenga. Nokho, ngaphambi kokucwengwa, igolide elingcolile lidinga ukuguqulwa libe uhlobo oluzuzisa inqubo yokucwengisiswa. Yilapho ukukhiqiza ama-flakes noma izimpushana kuba bucayi.

Inqubo yokuguqula ingxube yegolide ibe ama-flakes noma impushana iyisinyathelo esibalulekile enqubweni yokucwenga. Kubandakanya ukusebenzisa imishini ekhethekile ukuguqula ingxube yegolide eqinile ibe yifomu oyifunayo. Lawa ma-flakes noma ama-powder anendawo enkulu, okwenza kube lula ukucwenga amakhemikhali ukuze ahlangane nokungcola futhi akususe ngokuphumelelayo.

Enye yezinzuzo eziyinhloko zokusebenzisa umshini wokwenza i-metal flake yikhono lokukhiqiza ama-flakes noma ama-powders angaguquki futhi afanayo. Lokhu kufana kubalulekile ekuqinisekiseni ukuthi inqubo yokucwenga iqhubeka kahle nangempumelelo. Umshini uyakwazi ukukhiqiza njalo ama-alloys egolide ngendlela oyifunayo, okubalulekile ekutholeni igolide elicwengisisiwe lekhwalithi ephezulu.

Ngaphezu kwalokho, ukukhiqizwa kwama-flakes noma izimpushana kusiza futhi ukuxuba okuphumelelayo kwama-alloys egolide namakhemikhali okucwenga. Indawo enkulu yama-flakes ivumela ukusebenzisana okungcono phakathi kwegolide namakhemikhali, ukuqinisekisa ukukhomba okuphumelelayo nokususwa kokungcola phakathi nenqubo yokucwenga.

Ngaphezu kokusiza inqubo yokucwenga, ukukhiqizwa kwama-flakes noma ama-powder futhi kusiza ukulinganiswa okunembile kwama-alloys egolide. Ukufana kwama-flakes kuqinisekisa ukuthi inani eliqondile legolide lisetshenziselwa inqubo yokucwenga, okuholela emiphumeleni enembile nenembile.

Ngaphezu kwalokho, ukusetshenziswa kwemishini yokwenza i-metal flake nakho kunomthelela ekuphepheni okuphelele kwenqubo yokucwenga. Ngokukhiqiza ama-flakes noma izimpushana, ingozi yokuchayeka kumakhemikhali ayingozi iyancishiswa ngoba indawo enkulu engaphezulu ivumela ukuqukatha nokulawula okungcono phakathi nenqubo yokucwenga.

Kubalulekile ukuqaphela ukuthi ikhwalithi yama-flakes noma i-powder ekhiqizwayo ibalulekile ekuphumeleleni kwenqubo yokucwenga. Ngakho-ke, kubalulekile ukukhetha umshini wokwenza insimbi othembekile, osezingeni eliphezulu. Umshini kufanele ukwazi ukukhiqiza ama-flakes ahambisanayo, afanayo kanye nekhwalithi ephezulu noma i-powder ukuze kuqinisekiswe ukusebenza kahle kwenqubo yokucwenga.

Kafushane, ukukhiqiza ama-flakes noma izimpushana ezivela kuma-alloys egolide kuyisinyathelo esibalulekile enqubweni yokucwenga. Ukusetshenziswa kwemishini yokwenza i-metal flake kudlala indima ebalulekile ekufezeni lesi sinyathelo esibalulekile, okusiza ukwandisa ukusebenza kahle, ukunemba nokuphepha kwenqubo yokucwenga. Ngokukhiqiza umfaniswano, ama-flakes ekhwalithi ephezulu noma impushana, umshini usiza ukususa ukungcola ngempumelelo futhi ukhiqize igolide elicwengekile eliphezulu kakhulu.

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115