Customized Hasung Gold Casting Gold Umatshini wokusulungekisa Gold iiflakes Ukwenza oomatshini abavelisi abavela eTshayina | Hasung

I-Hasung inokuhambisa i-Hasung bullion yokukhupha umatshini wokusulungekisa igolide Izixhobo zokusulungekisa iGolide Iiflethi zeGolide Ukwenza uMatshini owona mgangatho uphezulu ngamaxabiso aphantsi.Sisoloko siqinisekisa ukuba abathengi bafumana oko bakufunayo.

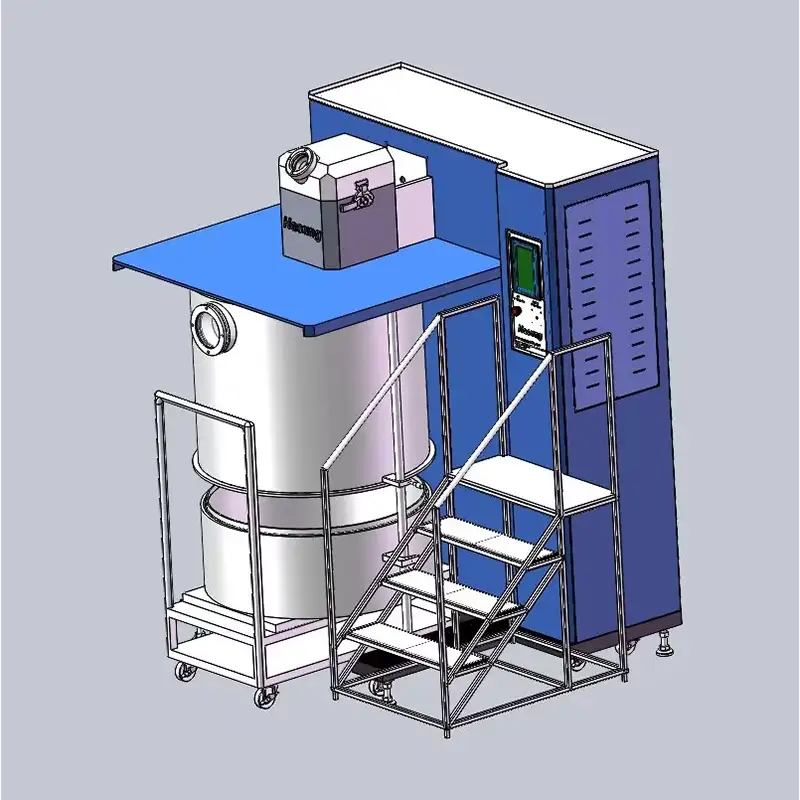

I-Hasung Gold Casting Gold Refining Machine Gold Flakes Making Machine xa kuthelekiswa neemveliso ezifanayo kwimarike, ineenzuzo ezibalaseleyo ezingenakuthelekiswa nanto malunga nokusebenza, umgangatho, ukubonakala, njl., kwaye inandipha igama elihle kwi-market.Hasung ishwankathela iziphene zeemveliso ezidlulileyo, kwaye ngokuqhubekayo iphucula. Iinkcukacha zeHasung Gold Casting Gold Refining Machine Gold Flakes Making Machine ungenziwa ngokwezifiso ngokweemfuno zakho.

Inkcazo yobuGcisa

| Umzekelo No. | HJ-MS5 | HJ-MS8 | HJ-MS30 | HJ-MS50 |

| I-Voltage | 380V, 50Hz, 3 izigaba | 380V, 50Hz, 3 izigaba | 380V, 50Hz, 3 izigaba | 380V, 50Hz, 3 izigaba |

| Amandla | 10KW | 15KW | 30KW | 30KW/50KW |

| Ubushushu obukhulu | 1500 ℃ | 1500 ℃ | 1500 ℃ | 1500 ℃ |

| Ixesha lokunyibilika | 2-3 imiz. | 2-5 imiz. | 4-6 imiz. | 10-15mim. |

| Igesi ekhuselayo | Argon/Nitrogen | |||

| Isicelo | Igolide, isilivere, ii-alloys zobhedu (i-Platinum alloys, i-palladium alloys) | |||

| Indlela yokupholisa | Ichiller yamanzi/Amanzi abalekayo | |||

| Ubukhulu beeflaski | 0.1-0.5mm | |||

| Inkqubo yokulawula | Iphaneli yokuchukumisa yeTaiwan Weinview/Siemens PLC | |||

| Indlela yokusebenza | Ukusebenza okungundoqo okukodwa ukugqiba yonke inkqubo, inkqubo ye-POKA YOKE engenangqondo | |||

| Imilinganiselo | 1120x1080x1750mm | 1260x1060x1920mm | ||

| 280kg | 400kg | |||

Iiflakes zegolide

Iiflakes zePlatinam

Isihloko: Ukubaluleka kweeflakes zealloyi yegolide kwinkqubo yokusulungekiswa

Ukusulungekiswa kwegolide yinkqubo ecokisekileyo efuna ukuchaneka kunye nengqalelo kwiinkcukacha. Ngaphambi kokuba umsebenzi wokusulungekiswa uqalise, igolide engcolileyo kufuneka iguqulwe ibe ngamaflakes okanye umgubo. Apha kulapho oomatshini bokwenza amaphepha entsimbi bangena khona. Kule bhlog, siza kuhlolisisa ukubaluleka kwee-alloy flakes zegolide kwinkqubo yokucoca kunye nendima ye-metal flake eyenza oomatshini ekufezekiseni eli nyathelo elibalulekileyo.

I-alloys yegolide yindibaniselwano yegolide kunye nezinye iintsimbi, ezihlala ziqulethe ukungcola okufuneka kususwe ngenkqubo yokucokisa. Noko ke, ngaphambi kokusulungekiswa, igolide engcolileyo kufuneka iguqulelwe ekubeni ibe luncedo kumsebenzi wokusulungekiswa. Kulapho ukuvelisa iiflakes okanye umgubo kubalulekayo.

Inkqubo yokuguqula i-alloy yegolide ibe yi-flakes okanye i-powder linyathelo elibalulekileyo kwinkqubo yokucoca. Kubandakanya ukusebenzisa oomatshini abakhethekileyo ukuguqula i-alloy yegolide eqinileyo ibe yifom efunwayo. Ezi flakes okanye iipowder zinendawo enkulu, eyenza kube lula ukucocwa kweekhemikhali ukusebenzisana nokungcola kunye nokuzisusa ngokufanelekileyo.

Enye yeenzuzo eziphambili zokusebenzisa umatshini wokwenza i-metal flake kukukwazi ukuvelisa iiflakes ezihambelanayo kunye ezifanayo okanye iipowders. Oku kufana kubalulekile ekuqinisekiseni ukuba inkqubo yokusulungekiswa iqhuba kakuhle nangempumelelo. Lo matshini uyakwazi ukusoloko uvelisa ialloys zegolide ngendlela efunwayo, nto leyo ibalulekileyo ekufumaneni igolide esulungekisiweyo ekumgangatho ophezulu.

Ukongeza, ukuveliswa kwee-flakes okanye iipowders kukwaququzelela ukuxuba ngokufanelekileyo kwee-alloys zegolide kunye neekhemikhali zokucoca. Ummandla omkhulu weeflakes uvumela ukusebenzisana okungcono phakathi kwegolide kunye neekhemikhali, ukuqinisekisa ukujoliswa okusebenzayo kunye nokususwa kokungcola ngexesha lenkqubo yokucocwa.

Ukongeza ekuququzeleleni inkqubo yokucoca, ukuveliswa kweeflakes okanye iipowders kukwaququzelela umlinganiselo ochanekileyo wee-alloys zegolide. Ukufana kweeflakes kuqinisekisa ukuba inani elichanekileyo legolide lisetyenziselwa inkqubo yokucoca, okubangelwa iziphumo ezichanekileyo nezichanekileyo.

Ukongezelela, ukusetyenziswa kwemishini yokwenza i-metal flake nayo igalelo ekukhuselekeni ngokubanzi kwenkqubo yokucoca. Ngokuvelisa iiflakes okanye iipowders, umngcipheko wokuvezwa kweekhemikhali ezinobungozi uyancitshiswa ngenxa yokuba indawo enkulu yomhlaba ivumela ukugcinwa okungcono kunye nokulawula ngexesha lokucoca.

Kubalulekile ukuba uqaphele ukuba umgangatho wee-flakes okanye i-powder eveliswayo ibaluleke kakhulu kwimpumelelo yenkqubo yokucoca. Ke ngoko, kubalulekile ukukhetha umatshini othembekileyo, okumgangatho ophezulu wokwenza intsimbi. Umatshini kufuneka ukwazi ukuvelisa i-flakes ehambelanayo, efanayo kunye nekhwalithi ephezulu okanye i-powder ukuqinisekisa ukusebenza kwenkqubo yokucoca.

Isishwankathelo, ukuvelisa iiflakes okanye iipowders ezivela kwi-alloys zegolide linyathelo elibalulekileyo kwinkqubo yokucoca. Ukusetyenziswa kwemishini yokwenza i-metal flake idlala indima ebalulekileyo ekufezekiseni eli nyathelo elibalulekileyo, linceda ukwandisa ukusebenza kakuhle, ukuchaneka kunye nokhuseleko lwenkqubo yokucoca. Ngokuvelisa iyunifomu, i-flakes ephezulu okanye i-powder, umatshini unceda ngokufanelekileyo ukususa ukungcola kwaye uvelise umgangatho ophezulu wegolide ecocekileyo.

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjineli boomatshini ekwimazantsi eTshayina, kwisixeko esihle nesikhula ngokukhawuleza kwezoqoqosho, iShenzhen. Le nkampani yinkokheli kwezobuchwepheshe kwicandelo lezixhobo zokufudumeza nokuthunga izixhobo zesinyithi esixabisekileyo kunye neshishini lezinto ezintsha.

Ulwazi lwethu olomeleleyo kubuchwepheshe bokuphosa i-vacuum lusenza sikwazi ukunceda abathengi bemizi-mveliso ukuphosa intsimbi exutywe kakhulu, i-platinum-rhodium alloy efunekayo kakhulu, igolide nesilivere, njl.

Umnxeba: +86 17898439424

I-imeyile:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Idilesi: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115