Hasung - Lub Hoobkas Muab Platinum Induction Melting Tshuab nrog 2Kg-8kg rau Melting Kub Nyiaj Platinum Palladium

Sai li lub Hoobkas muab khoom lag luam jewelery machinery 2kg 3kg 4kg 5kg 6kg platinum induction melting tshuab kub smelting khoom twb launched nyob rau hauv lub lag luam, nws tau txais zoo tswv yim los ntawm ntau cov neeg muas zaub, uas hais tias hom khoom no muaj peev xwm daws tau lawv cov kev xav tau. Tsis tas li ntawd, cov khoom yog dav siv nyob rau hauv Industrial Furnaces.

Shenzhen Hasung Precious Metals Equipment Co., Ltd tau dhau los ua tus thawj coj hauv kev lag luam Furnaces nrog nws cov khoom zoo thiab kev pabcuam zoo heev. Cov khoom siv dav siv los daws cov teeb meem tshwm sim hauv thaj chaw ntawm Industrial Furnaces. Tsav los ntawm lub tuam txhab lub zeem muag ntawm 'ua cov chaw tsim khoom tshaj lij thiab cov neeg xa khoom zoo tshaj plaws hauv kev lag luam thoob ntiaj teb', Shenzhen Hasung Precious Metals Equipment Co., Ltd yuav xyuam xim ntxiv rau kev txhim kho R & D lub zog, txuas ntxiv txhim kho thev naus laus zis, thiab txhim kho lub koom haum cov qauv. Peb txhawb kom txhua tus neeg ua haujlwm koom ua ke hauv cov txheej txheem no los tsim kom muaj lub neej yav tom ntej zoo rau lub tuam txhab.

Qhov zoo:

3. Self-maufactured tswj board.

Technical Specification

| Qauv No. | HS-MU1 | HS-MU2 | HS-MU3 | HS-MU4 | HS-MU5 | HS-MU6 | HS-MU8 | HS-MU10 |

| Qhov hluav taws xob | 380V 50/60Hz, 3 P | 380V 50/60Hz, 3 theem | 380V 50/60Hz, 3 theem | |||||

| Hwj chim | 10KW | 15KW | 15KW | 15KW/20KW | ||||

| Peev xwm (kub) | 1kg ua | 2kg ua | 3kg ua | 4kg ua | 5kg ua | 6kg ua | 8kg ua | 10kg ua |

| Max Temp | 1600 ° C / 2100 ° C | |||||||

| Lub sij hawm yaj | 1-2 feeb. | 1-2 feeb. | 2-3 feeb. | 2-3 feeb. | 3-5 feeb. | 2-3 feeb. | 3-5 feeb. | 5-8 feeb. |

| Temp raug | ±1°C | |||||||

| PID temp tswj | xaiv tau | |||||||

| Daim ntawv thov | Platinum, Palladium, Stainless hlau, Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys | |||||||

| Hom cua txias | Dej chiller (muag nyias) los yog dej khiav (dej twj tso kua mis muag nyias) | |||||||

| Qhov ntev | 560 x 480 x 880 mm | |||||||

| Net nyhav | cav 60kg | kwv yees. 62kg ua | kwv yees. 65kg ua | kwv yees. 66kg ua | kwv yees. 68kg ua | kwv yees. 70kg ua | kwv yees. 75kg ua | kwv yees. 80kg ua |

| Shipping hnyav | kwv yees. 92kg ua | kwv yees. 95kg ua | kwv yees. 96kg ua | kwv yees. 98kg ua | kwv yees. 105kg ua | kwv yees. 110kg ib | kwv yees. 120 kg | kwv yees. 130kg ib |

PS:

Thov hu rau peb rau koj qhov kev thov ntawm cov hlau koj xav tau yaj.

Packing cov ntsiab lus:

Dej chiller (dej txias system) muag cais yog tias xav tau.

Kev piav qhia

Product Description"

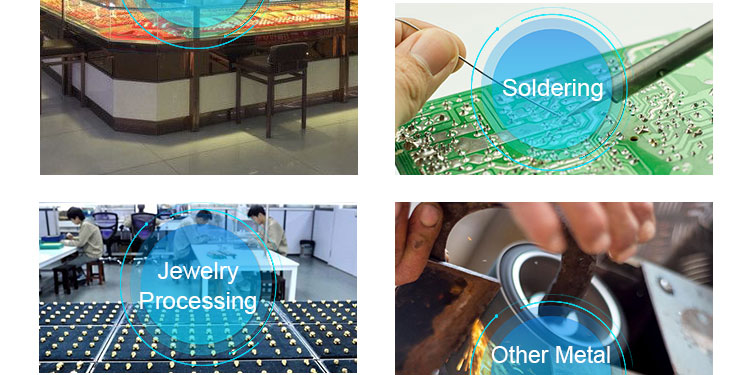

Daim ntawv thov:

Taw qhia Induction Melting Rauv: Revolutionizing Hlau Melting

Koj puas xav tau ib qho kev txhim khu kev qha thiab ua tau zoo ntawm cov hlau melting? Peb lub xeev-of-the-art induction melting furnaces yog koj cov lus teb. Nrog nws cov kev ua tau zoo, kev ua haujlwm zoo thiab muaj peev xwm yaj tau nrawm, lub tshuab hluav taws xob no yog tsim los ua kom tau raws li cov kev xav tau sib txawv ntawm kev ua haujlwm hlau melting. Txawm hais tias koj tab tom ua cov khoom me me lossis cov hlau loj, peb cov induction melting furnaces muaj nyob rau hauv ntau qhov sib txawv kom tau raws li koj cov kev xav tau tshwj xeeb.

Ua nrog precision thiab advanced technology, peb induction melting rauv yog zoo meej rau industries xws li foundries, metalworking thiab manufacturing. Nws txoj kev tsim kho tshiab thiab kev ua tau zoo dua ua rau nws muaj txiaj ntsig zoo rau cov lag luam tab tom nrhiav kom kho lawv cov txheej txheem hlau melting thiab ua kom cov khoom tsim tau.

Cov yam ntxwv tseem ceeb thiab cov txiaj ntsig:

1. High Quality: Peb lub qhov cub induction melting yog tsim los rau cov qauv siab tshaj plaws, ua kom muaj kev ruaj khov thiab kev ntseeg siab nyob rau hauv qhov kev xav tau ntau tshaj plaws. Kev siv cov ntaub ntawv zoo thiab cov khoom siv tes ua haujlwm zoo tau lees paub lub neej ua haujlwm ntev thiab ua haujlwm zoo ib yam.

2. Kev ua haujlwm zoo: Txhua qhov kev nthuav dav ntawm peb lub qhov cub induction melting yog ua tib zoo tsim los muab cov txiaj ntsig zoo. Los ntawm kev tsim cov cua kub ntsiab lus rau kev tsim kho ntawm lub crucible, txhua yam khoom yog precision crafted los xyuas kom meej efficiency thiab efficiency.

3. Ceev nrooj yaj: Nrog cov cuab yeej siv hluav taws xob zoo tshaj plaws, peb lub cub tawg tuaj yeem yaj ntau hom hlau, xws li hlau, hlau, tooj liab, thiab txhuas. Qhov kev ceev thiab kev ua tau zoo no tsis tsuas yog txuag lub sijhawm tab sis kuj txo qis kev siv zog, ua rau nws muaj txiaj ntsig zoo rau kev ua haujlwm hlau melting.

4. Muaj peev xwm ntau lawm: Peb nkag siab tias cov tuam txhab sib txawv muaj cov kev xav tau ntau lawm. Tias yog vim li cas peb cov induction melting rauv muaj nyob rau hauv ntau lub peev xwm, tso cai rau koj xaiv qhov loj me uas zoo tshaj plaws rau koj cov kev xav tau melting. Txawm hais tias koj xav tau lub cub tawg me me, nruab nrab lossis loj, peb muaj cov kev daws teeb meem zoo tshaj plaws rau koj.

5. Cov neeg siv-phooj ywg ua haujlwm: Peb lub qhov cub induction melting yog tsim los siv tau yooj yim, nrog kev tswj xyuas qhov tseeb thiab cov neeg siv khoom zoo. Qhov no ua kom cov neeg ua haujlwm tuaj yeem tswj cov txheej txheem melting zoo nrog kev cob qhia tsawg, uas ua rau muaj kev tsim khoom ntau ntxiv thiab txo qis sijhawm.

6. Versatility: Los ntawm melting thiab alloying rau refining thiab casting, peb induction melting furnaces muaj peev xwm ua tau ntau yam hlau ua hauj lwm. Nws versatility ua rau nws muaj txiaj ntsig zoo rau cov lag luam koom nrog ntau yam kev siv hlau ua haujlwm.

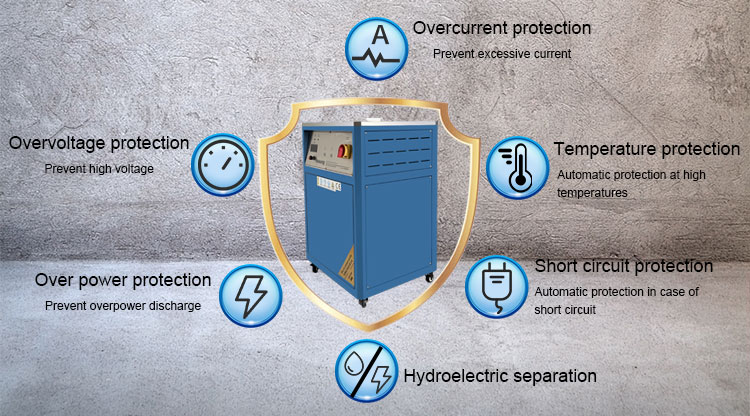

7. Kev Nyab Xeeb Nta: Kev nyab xeeb yog qhov tseem ceeb nyob rau hauv ib puag ncig kev lag luam, thiab peb cov induction melting furnaces tau nruab nrog cov yam ntxwv zoo tshaj plaws los tiv thaiv tus neeg teb xov tooj thiab ib puag ncig ib puag ncig. Los ntawm kev saib xyuas qhov kub thiab txias mus rau lub kaw lus kaw thaum muaj xwm txheej ceev, peb ua qhov tseem ceeb rau kev noj qab haus huv ntawm peb cov neeg siv.

Daim ntawv thov:

Lub versatility thiab efficiency ntawm peb induction melting rauv ua rau lawv haum rau ntau yam kev siv, xws li tab sis tsis txwv rau:

- chaw tsim khoom

- Hlau casting thiab sib sau

- Kev tsim khoom hlau

- Automotive thiab aerospace kev lag luam

- Kev tsim khoom siv hluav taws xob thiab hluav taws xob

- Cov hniav nyiaj hniav kub thiab cov khoom siv hlau muaj nuj nqis

Tag nrho cov nyob rau hauv tag nrho, peb induction melting furnaces yog ib tug kev ua si-hloov rau cov lag luam nrhiav kev txhim khu kev qha, high-kev ua tau zoo hlau melting daws. Nws kev sib xyaw ua ke ntawm cov khoom zoo, kev ua haujlwm zoo, muaj peev xwm yaj tau sai thiab muaj peev xwm sib txawv ua rau nws muaj kev xaiv ntau yam thiab raug nqi rau ntau yam kev lag luam. Nrog peb cov induction melting furnaces, koj tuaj yeem nqa cov kev ua tau zoo thiab kev tsim khoom ntawm koj cov txheej txheem hlau melting mus rau qib tshiab. Kawm paub qhov txawv nrog peb cov qib siab induction melting rauv thiab coj koj cov haujlwm ua haujlwm hlau mus rau qib tom ntej.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115