Hasung inyanzvi yekugadzira michina yekukanda nekunyungudutsa simbi dzinokosha kubvira muna 2014.

Hasung - Factory Supply Platinum Induction Melting Machine ine 2Kg-8kg yekunyungudutsa Gold Silver Platinum Palladium.

Pakangotangwa pamusika michina yeFactory Supply jewellery 2kg 3kg 4kg 5kg 6kg platinum induction meting machine goridhe yekunyungudutsa, yakagamuchira mhinduro yakanaka kubva kune vatengi vazhinji, avo vakati rudzi urwu rwechigadzirwa runogona kugadzirisa zvavanoda.

Shenzhen Hasung Precious Metals Equipment Co., Ltd yave mutungamiri anozivikanwa muIndustrial Furnaces indasitiri ine chigadzirwa chemhando yepamusoro uye sevhisi yakanaka. Chigadzirwa chacho chinoshandiswa zvakanyanya kugadzirisa matambudziko arikumuka mumunda (s) weIndustrial Furnaces. Ichitungamirirwa nechiratidzo chekambani 'chekuve mugadziri ane hunyanzvi uye mutengesi akavimbika kwazvo pamusika wepasirese', Shenzhen Hasung Precious Metals Equipment Co., Ltd ichabhadhara zvakanyanya mukusimudzira simba reR&D, kuenderera mberi nekusimudzira matekinoroji, uye nekugonesa chimiro chesangano. Tinokurudzira vashandi vese kuti vabatane pamwechete muchirongwa ichi chekugadzira ramangwana rakanaka rekambani.

Zvakanakira:

3. Self-maufactured controller board.

Kutsanangurwa Kwehunyanzvi

| Muenzaniso Nha. | HS-MU1 | HS-MU2 | HS-MU3 | HS-MU4 | HS-MU5 | HS-MU6 | HS-MU8 | HS-MU10 |

| Voltage | 380V 50/60Hz, 3 P | 380V 50/60Hz, 3 chikamu | 380V 50/60Hz, 3 chikamu | |||||

| Simba | 10KW | 15KW | 15KW | 15KW/20KW | ||||

| Kugona (Goridhe) | 1kg | 2kg | 3kg | 4kg | 5kg | 6kg | 8kg | 10kg |

| Max Temp | 1600°C/2100°C | |||||||

| Nguva yekunyunguduka | 1-2 min. | 1-2 min. | 2-3 min. | 2-3 min. | 3-5 min. | 2-3 min. | 3-5 min. | 5-8 min. |

| Temp Accuracy | ±1°C | |||||||

| PID temp control | Optional | |||||||

| Application | Platinamu, Palladium, Stainless simbi, Goridhe, K goridhe, sirivheri, mhangura uye mamwe alloys | |||||||

| Kutonhora mhando | Chiller yemvura (inotengeswa zvakasiyana) kana Mvura inoyerera (pombi yemvura inotengeswa zvakasiyana) | |||||||

| Dimensions | 560x480x880mm | |||||||

| Net Weight | approx.60kg | approx. 62kg | approx. 65kg | approx. 66kg | approx. 68kg | approx. 70kg | approx. 75kg | approx. 80kg |

| Kutakura uremu | approx. 92kg | approx. 95kg | approx. 96kg | approx. 98kg | approx. 105kg | approx. 110kg | approx. 120kg | approx. 130kg |

PS:

Ndapota taura nesu nokuda kwekukumbira kwako kwesimbi yaunoda kunyunguduka.

Packing details:

Mvura chiller (water cooling system) inotengeswa zvakasiyana kana zvichidiwa.

Tsanangudzo

Product Description"

Application:

Kuunza iyo Induction Melting Furnace: Revolutionizing Metal Melting

Unoda yakavimbika uye inoshanda simbi kunyunguduka mhinduro? Yedu-ye-the-art induction yekunyungudutsa mavira ndiyo mhinduro yako. Nemhando yayo yemhando yepamusoro, kugadzirwa kwakanaka uye kugona kunyungudika nekukurumidza, choto ichi chakagadzirirwa kusangana nezvinodiwa zvakasiyana zvekunyunguduka kwesimbi. Kunyangwe iwe uri kugadzira zvidiki kana hukuru hwesimbi, yedu induction yekunyungudutsa mavira anowanikwa mune akasiyana siyana kuti asangane nezvako chaizvo zvaunoda.

Yakagadzirwa nehunyanzvi uye tekinoroji yepamusoro, yedu induction yekunyungudutsa mavira akanakira maindasitiri akadai seakawana, simbi uye kugadzira. Dhizaini yayo yekuvandudza uye kuita kwepamusoro kunoita kuti ive yakakosha kune mabhizinesi ari kutsvaga kugadzirisa maitiro avo ekunyungudusa simbi uye kuwedzera kugadzirwa.

Main maficha uye mabhenefiti:

1. High Quality: Yedu induction yakanyunguduka furnaces inogadzirwa kune yepamusoro-soro, kuve nechokwadi chekugara uye kuvimbika munzvimbo dzinonyanya kudiwa dzeindasitiri. Iko kushandiswa kwezvinhu zvemhando yepamusoro uye hunyanzvi hwekugadzira hunovimbisa hupenyu hurefu hwesevhisi uye kuita kwakafanana.

2. Kugadzirwa kwakanaka: Yese ruzivo rwedu induction yekunyungudutsa muvira yakanyatsogadzirwa kuti ipe mhedzisiro yakanaka. Kubva pakugadzirwa kwezvinhu zvekupisa kusvika pakuvakwa kwe crucible, chikamu chega chega chakanyatsogadzirwa kuti chive nechokwadi chekushanda kwakakwana uye kushanda.

3. Kukurumidza kunyunguduka: Neyepamusoro induction kupisa tekinoroji, choto chedu chinokwanisa kukurumidza kunyungudutsa marudzi akasiyana-siyana emasimbi, kusanganisira simbi, simbi, mhangura, uye aluminium. Kumhanya nekugona uku hakungochengetedze nguva chete asiwo kunoderedza kushandiswa kwesimba, zvichiita kuti ive mhinduro inodhura yekunyungudutsa simbi.

4. Zvigadzirwa zvakasiyana-siyana zvekugadzira: Tinonzwisisa kuti makambani akasiyana ane zvido zvakasiyana zvekugadzira. Ndosaka edu induction yekunyungudika mavira achiwanikwa akasiyana siyana, achikubvumidza iwe kuti usarudze saizi inonyatsoenderana neyako yekunyungudika zvaunoda. Kunyangwe iwe uchida diki, yepakati kana hombe yehuni yehuni, isu tine mhinduro yakakwana kwauri.

5. Mushandisi-ushamwari kushanda: Yedu induction melting furnaces yakagadzirirwa kuve nyore kushandisa, ine intuitive controls uye mushandisi-ushamwari interface. Izvi zvinoita kuti vashandisi vagone kubata nemazvo maitiro ekunyunguduka nekudzidziswa kushoma, zvichikonzera kuwedzera kubereka uye kuderedzwa nguva.

6. Kushanda kwakasiyana-siyana: Kubva pakunyunguduka uye kusanganiswa kusvika pakunatsa uye kukanda, mavheni edu ekunyunguduka anogona kuita mabasa akasiyana-siyana ekugadzira simbi. Kuita kwayo kwakasiyana-siyana kunoita kuti ive chinhu chakakosha kune mabhizinesi anobatanidzwa mune dzakasiyana siyana dzekugadzira simbi.

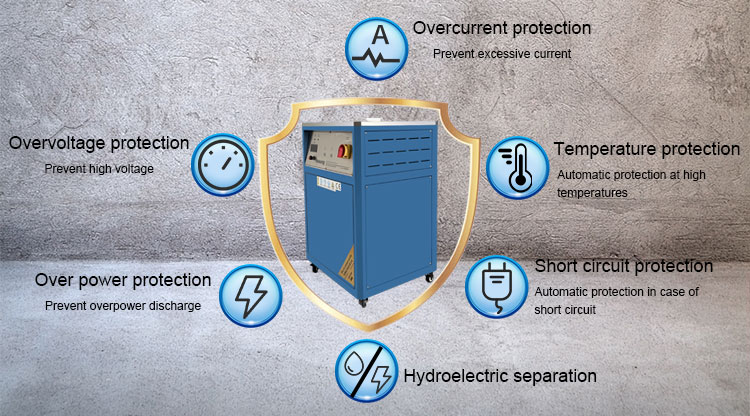

7. Chengetedzo Mamiriro: Kuchengetedzeka kwakakosha mune chero indasitiri nharaunda, uye yedu induction yakanyunguduka furnaces yakashongedzerwa nemhando yepamusoro yekuchengetedza kuchengetedza mushandisi uye nharaunda yakapoteredza. Kubva pakutarisisa tembiricha kusvika kune yekumisikidza kudzima masisitimu, tinoisa pamberi kugara zvakanaka kwevashandisi vedu.

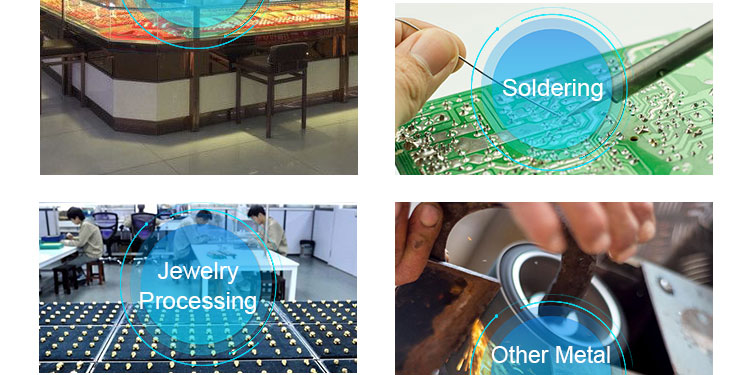

Application:

Iko kuita kwakasiyana-siyana uye kushanda nesimba kwemavira edu ekunyunguduka kunoita kuti ive yakakodzera kune dzakasiyana siyana dzekushandisa, kusanganisira asi kwete kugumira kune:

- foundry

- Metal kukandira uye kugadzira

- Metal kugadzira

- Indasitiri yemotokari uye aerospace

-Magetsi uye zvemagetsi chikamu chekugadzira

- Zvishongo uye simbi yakakosha kugadzirisa

Zvese mune zvese, yedu induction yekunyungudutsa mavira ndeye mutambo-wekuchinja kune mabhizinesi ari kutsvaga akavimbika, akanyanya-kuita simbi kunyunguduka mhinduro. Kusanganiswa kwayo kwemhando yepamusoro, kugadzirwa kwakanaka, kugona kunyungudika nekukurumidza uye kugona kwakasiyana kunoita kuti ive sarudzo inogoneka uye inodhura kune akasiyana maindasitiri ekushandisa. Neyedu induction yekunyungudutsa mavira, unogona kutora kunyatsoshanda uye kugadzirwa kwesimbi yako yekunyungudika maitiro kusvika kumazinga matsva. Sangana nemusiyano neyedu yepamusoro induction yekunyungudutsa mavira uye tora yako simbi kushanda kune inotevera nhanho.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ikambani yeinjiniya yemakanika iri kumaodzanyemba kweChina, muguta rakanaka uye riri kukura nekukurumidza muhupfumi, Shenzhen. Kambani iyi inotungamira muhunyanzvi hwetekinoroji munharaunda yemidziyo yekudziyisa nekukanda simbi dzinokosha neindasitiri yezvinhu zvitsva.

Ruzivo rwedu rwakasimba muhunyanzvi hwekukanda vacuum runotigonesawo kushandira vatengi vemaindasitiri kugadzira simbi ine musanganiswa wakawanda, platinum-rhodium alloy inodiwa ne musanganiswa wakawanda, goridhe nesirivha, nezvimwewo.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Kero: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115