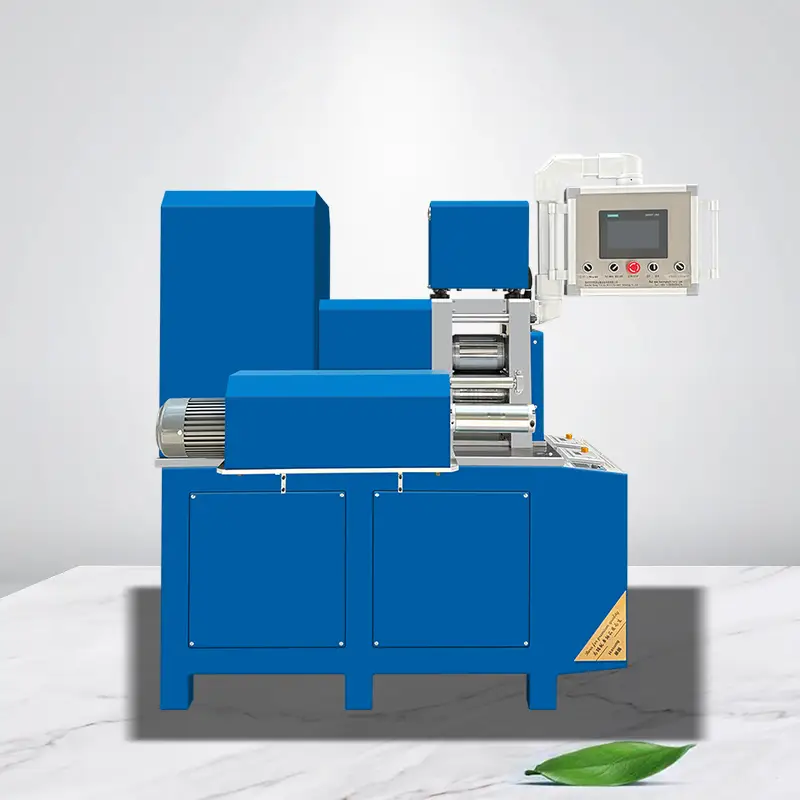

Hasung - 40HP Kub Sheet Rolling Mill Tshuab rau Kub Nyiaj Tin Alloys

Hasung 40HP kub ntawv dov zeb tshuab precisely txo kub, nyiaj thiab tin alloy strips rau uniform foils 0.01-2 hli ntawm ≤850 ° C. Hydraulic 40 HP servo lub cev muaj zog, 250 hli chromed yob, ± 1 µm sib txawv tswj, nitrogen cua, PLC daim ntawv qhia nco, kev nyab xeeb lub teeb curtains. Hais lus txaus siab, peb siv cov thev naus laus zis tshiab los tsim cov ntawv kub dov tshuab, nyiaj ntawv dov tshuab thiab cov hniav nyiaj hniav kub daim ntawv dov tshuab thiab lwm yam,. nws yog dav siv thiab txais heev.

Lub tshuab dov kub kub Hasung 40HP yog lub tshuab ua haujlwm hnyav uas tsim los rau kev dov cov hlau muaj nqis thiab cov hlau mos. Lub cev muaj zog servo 40 HP tsav 250 hli Ø forged-chrome dov los ntawm cov planetary reducers, muab qhov ceev tsis kawg 0–20 m/min thiab ±1 µm dov-qhov tseeb ntawm cov thooj voos kheej kheej hydraulic kaw. Lub chamber induction-heated 350 °C ua haujlwm hauv qab N₂ lossis Ar huab cua kom tiv thaiv kev oxidation; dual-zone pyrometers thiab IR sensors muab ±3 °C thermal tswj. Cov ntaub thaiv teeb pom kev zoo, ob chav e-stops, lubrication tsis siv neeg thiab overload clutches tiv thaiv tus neeg teb xov tooj thiab gearbox. Lub thav duab yog hlau-relieve-stress-relieve; yob yog HRC 60 chrome-plated nrog ±0.002 hli cylindricity. Txais 350 hli dav, 50 hli tuab feedstock.

40HP ultra-precision CNC kub ntawv dov tshuab: tshwj xeeb hauv kev ua cov kub tin, kub germanium, kub germanium nickel, sterling ntawv, tin bismuth, platinum rhodium, av tsawg thiab ntau yam alloys, cov nyhuv dov yog qhov zoo tagnrho heev.

| Qauv No. | HS-H40HP |

| Hluav taws xob | 380V 50hz, 3 theem |

| Lub zog | 30KW |

| Qhov loj ntawm cov menyuam | Txoj kab uas hla 220 * Dav 350 hli |

Cov lus qhia txog kev siv:

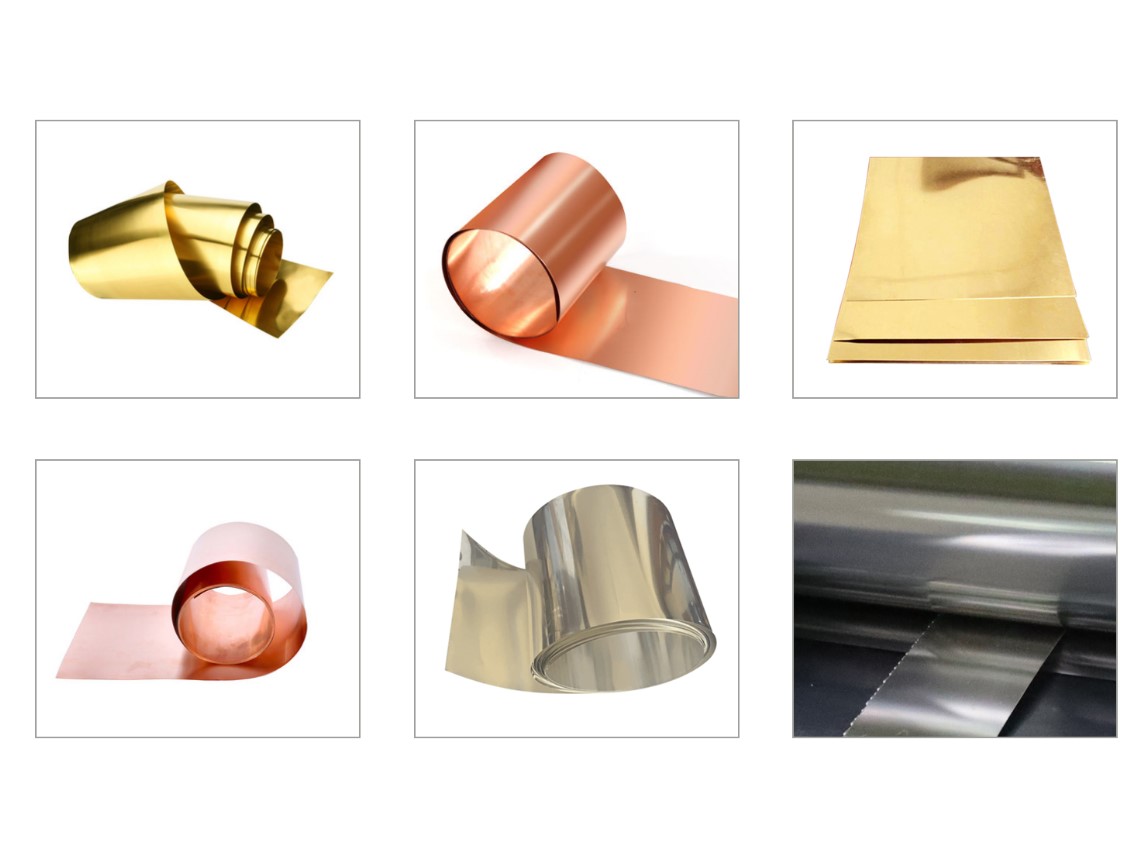

(1) Khoom siv: Kub-Tin, tin bismuth thiab lwm yam alloys

(2) cov khoom tuab: ≤50mm

Khoom tiav lawm

(1) cov khoom tiav tuab: ≥0.2 hli

(2) lub nruas rub rov qab, txoj kab uas hla: φ150 hli

Lwm yam kev teeb tsa:

(1) qhov kub ntawm cov menyuam: ≤300 ° C

(2) cov menyuam, kab ceev: ≤9.5 hli / feeb

(3) lub zog tsav: 15KW

(4) hom kev siv lub zog rau cov menyuam: kev tswj hwm tus lej servo

(5) hom kev tswj hwm downforce rau cov menyuam: CNC downforce, txhua qhov chaw teeb tsa tau, ib qho

kho tau,

(6) dov down kev hloov kho qhov tseeb: 0.001 hli

(7) Tshuab loj (txog): 1850X 1180x 1990mm

Cov txiaj ntsig ntawm Hasung 40HP Kub Hlau Thiab Ntawv Dov Tshuab

• Kev ntsuas qhov tseeb heev: ±1 µm kev tswj hwm servo dov-qhov sib txawv ua rau muaj 0.02–2 hli kub, nyiaj, thiab hlau alloy nrog daim iav tiav, zoo tagnrho rau kev tsim cov hniav nyiaj hniav kub zoo tshaj plaws.

• Kev siv tau ntau yam: cov cassettes dov sib pauv tau hloov lub tshuab los ntawm hlau mus rau kev dov tiaj tus, cia ib lub tshuab dov ntawv me me ua haujlwm ntau yam txheej txheem.

• Huab cua tswj tau: Chav nitrogen tiv thaiv kev oxidation, ua kom cov nplaim ci, thiab yooj yim solder los ntawm cov chaw goldsmith rolling mills thoob ntiaj teb.

Cov ntawv thov:

Lub tshuab dov kub Hasung 40HP yog tsim los ua cov hlau kub, nyiaj thiab tin ua cov hlau sib xyaw ua cov ntawv nyias nyias, sib xws rau cov lag luam muaj nqis siab. Hauv kev tsim cov hniav nyiaj hniav kub, lub tshuab dov ntawv hniav nyiaj hniav kub tsim cov ntawv kub karat-kub ci rau cov nplhaib, cov hlua tes thiab cov pendants, thaum cov chaw ua minting vam khom nws los dov cov bullion blanks rau cov npib thiab cov tuav. Cov chaw kuaj hniav siv lub tshuab dov ntawv los dov cov hlau sib xyaw biocompatible rau cov yas thiab cov choj, thiab cov kws ua kom zoo nkauj tshwj xeeb siv nws rau cov anodes nyias thiab cov ntawv ci hauv electroplating. Lub tshuab dov hlau yog qhov tseem ceeb rau txhua lub chaw ua haujlwm uas xav tau cov txiaj ntsig rov ua dua, tsis muaj oxidation los ntawm cov khoom siv hlau muaj nqis.

Txawm koj xav tau lub tshuab dov ntawv kub lossis lub tshuab dov hlau thiab ntawv, Hasung tuaj yeem muab nws!

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115