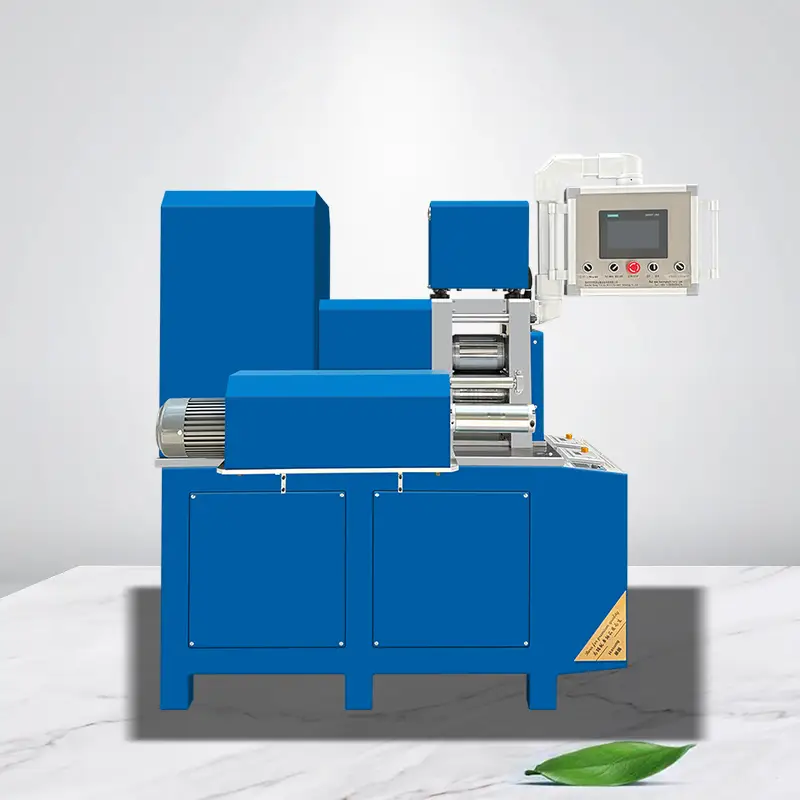

Hasung - 40HP Hot Sheet Rolling Mill Machine for Gold Silver Tin Alloys

Hasung 40HP hot sheet rolling mill machine precisely reduces gold, silver and tin alloy strips to uniform foils 0.01–2 mm at ≤850 °C. Hydraulic 40 HP servo motor, 250 mm chromed rolls, ±1 µm gap control, nitrogen atmosphere, PLC recipe memory, safety light curtains. Proudly speaking, we utilize the upgraded technologies to manufacture the gold sheet rolling machine, silver sheet rolling machine and jewelry sheet rolling machine etc,. it is widely used and highly accepted.

Hasung 40HP hot goldsmith rolling mill is a heavy-duty precision machine purpose-built for hot-rolling precious and soft metal strips. A 40 HP servo motor drives 250 mm Ø forged-chrome rolls through planetary reducers, giving infinitely variable 0–20 m/min speed and ±1 µm roll-gap accuracy via closed-loop hydraulic cylinders. The 350 °C induction-heated chamber works under N₂ or Ar atmosphere to stop oxidation; dual-zone pyrometers and IR sensors give ±3 °C thermal control. Safety light curtains, dual e-stops, automatic lubrication and overload clutches protect operator and gearbox. Frame is stress-relieved steel; rolls are HRC 60 chrome-plated with ±0.002 mm cylindricity. Accepts 350 mm wide, 50 mm thick feedstock.

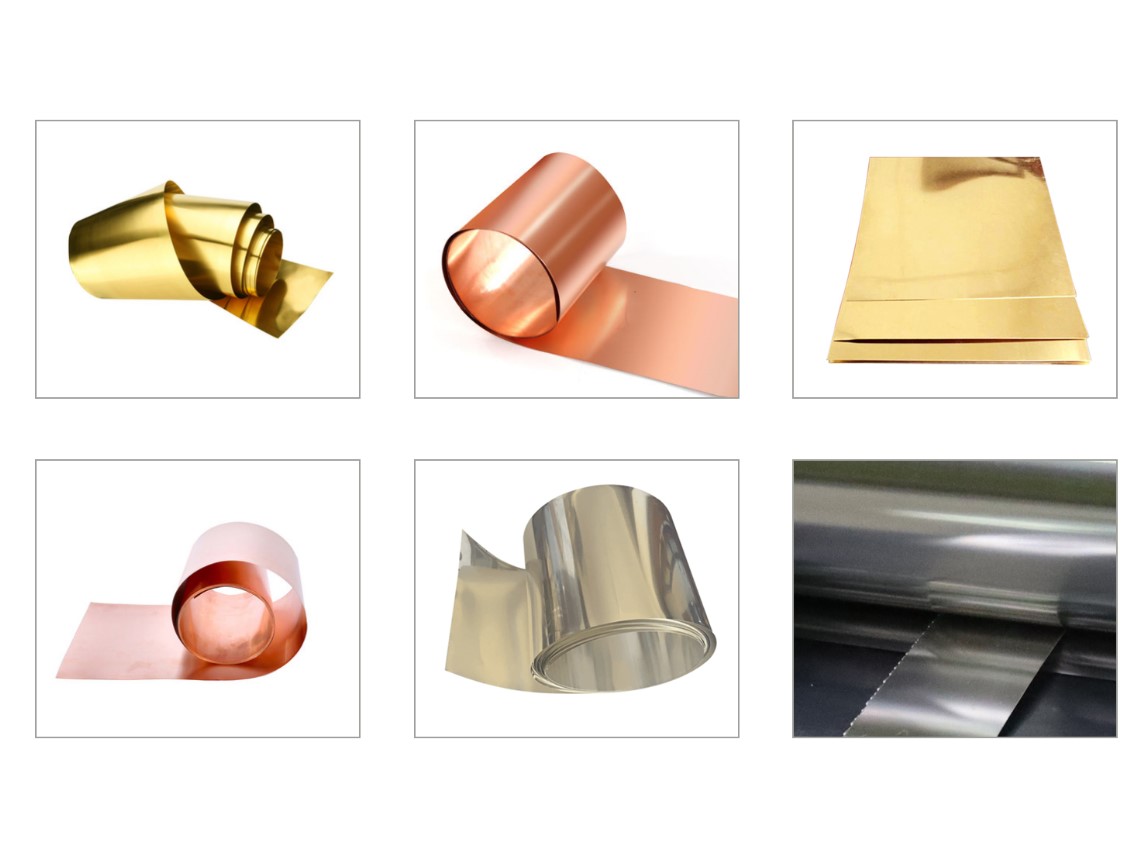

40HP ultra-precision CNC hot sheet rolling mill machine: specializing in the processing of gold tin, gold germanium, gold germanium nickel, sterling sheet, tin bismuth, platinum rhodium, rare earth and multiple alloys, the rolling effect is very ideal.

| Model No. | HS-H40HP |

| Voltage | 380V 50hz, 3 phases |

| Power | 30KW |

| Roller size | Diameter 220 * Width 350 mm |

Technical specifications:

(1) Material: Gold-Tin, tin bismuth and other alloys

(2) material thickness: ≤50mm

Finished product

(1) finished product thickness: ≥0.2 mm

(2) retractable drum, diameter: φ150 mm

Other parameters:

(1) roller temperature: ≤300 ° C

(2) roller, line speed: ≤9.5 mm/min

(3) motor power: 15KW

(4) roller downforce mode: servo numerical control

(5) roller downforce regulation mode: CNC downforce, all setting adjustable, single

adjustable,

(6) roll down adjustment accuracy: 0.001 mm

(7) Machine size (about) : 1850X 1180x 1990mm

Advantages of Hasung 40HP Hot Wire And Sheet Rolling Machine

• Ultra-precision: ±1 µm roll-gap servo control yields 0.02–2 mm gold, silver, tin alloy sheets with mirror finish, ideal for high-end jewelry production.

• Versatile throughput: interchangeable roll cassettes convert the unit from wire to flat rolling, letting one compact sheet rolling machine serve multiple processes.

• Controlled atmosphere: nitrogen chamber prevents oxidation, ensuring bright, solderable surfaces demanded by goldsmith rolling mills worldwide.

Applications:

Hasung’s 40HP hot sheet rolling mill is engineered to process gold, silver and tin alloys into ultra-thin, uniform sheets and foils for high-value markets. In jewelry manufacture, jewelry sheet rolling machine produces bright karat-gold sheets for rings, bracelets and pendants, while minting facilities rely on it to roll bullion blanks for coins and bars. Dental laboratories use sheet rolling mill to roll biocompatible alloy ribbons for crowns and bridges, and specialty refiners employ it for thin anodes and target foils in electroplating. The metal rolling mill is indispensable for any workshop demanding repeatable, oxidation-free results from precious-metal feedstock.

Whether you need a gold sheet rolling machine or a wire and sheet rolling machine, Hasung can provide it!

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115