Product Introduction

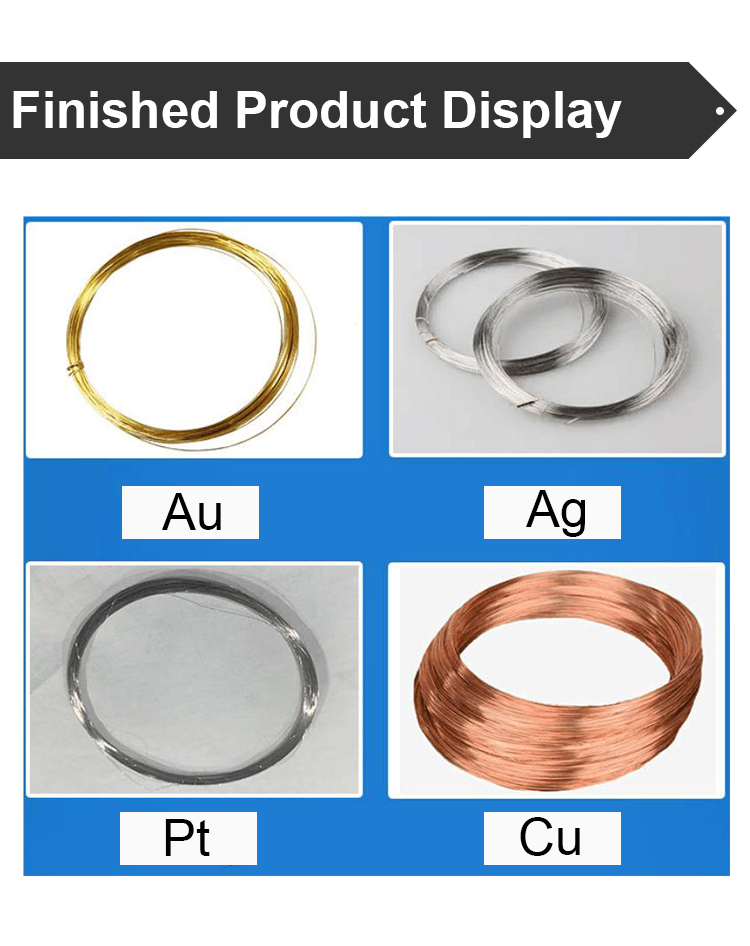

Wire drawing machine is application for reducing wire sizes for gold, silver, copper, platinum,etc. The machine has 12 channels for wires passing through dies, maximum can be input 24 dies. Wire drawing machine is widely used for gold silver jewellery, precious metals wire processing, and other purposes.

Features

1. 12 pass wire drawing

2. With highest quality

3. Wire winder device included

4. With cover

Specification

| Model No. | HS-1123 |

| Voltage | 380V, 3 phase, 50/60Hz |

| Power | 3.5KW |

| Fastest Speed | 55 meters / minute |

| Capability | 1.2mm - 0.1mm; maximum can place 24 dies at a time. |

| Cooling way | Automatic liquid cooling |

| Wire dies | customized (sold separately) |

| Machine size | 1620*780*1280mm |

| Weight | Approx. 380kg |

Company Advantages

Our factory has passed the ISO 9001 international quality certification

More than 30 patents for machines.

We select raw material suppliers carrying the certificates that 100% guarantee the materials and apply world famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc.

Frequently Asked Questions about goldsmith mill

Q:Q. Do you accept OEM business?

A:A. Yes, we are OEM supplier.

Q:Q. What is the standard of package?

A:A. Export standard package with plywood packing.

Q:Q: If I place an order on you, how should I pay?

A:A: Generally, T / T, Visa, West Union and other payment methods are acceptable.

Q:Q: How long does your machine warranty last?

A:A: Two years warranty.

Q:Q: How about the shipping costs and tax?

A:A: The cost of delivery depends on the mode, destination and weight. The tax depends on your local customs. When by DDP term, all customs clearance fees and taxes are inlcuded and prepaid. When by CIF term, or DDU term, customs duties and taxes will be known and paid when arrival.

More FAQs

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

About Hasung

Shenzhen Hasung Precious Metals Equipment Co., Ltd. is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry.

Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc. Our mission is to build the most innovative heating and casting equipment for precious metal manufacturing and gold jewellery industry, providing customers with the highest reliability in your daily operations and the best quality. We are acknowledged in the industry as a technology leader. What we're deserved to be proud is our vacuum and high vacuum technology is the best in China. Our equipment, manufactured in China, is made of highest-quality components, apply worldwide famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc.

Hasung has proudly served the precious metal casting & forming industry with vacuum pressure casting equipment,

continuous casting machine, high vacuum continuous casting equipment, vacuum granulating equipment, induction melting furnaces, gold silver bullion vacuum casting machine, metal powder atomizing equipment, etc.

Our R & D department is always working on developing casting and melting technologies to suit our ever changing industry for the New Materials industry, Aerospace, Gold Mining, Metal Minting Industry, Research laboratories, Rapid Prototyping, Jewellery, and Artistic Sculpture. We do provide precious metals solutions for customers. We uphold the principle of "integrity, quality,cooperation, win-win" business philosophy,committed to creating first-class products and services. We always believe that technology changes the future.

We specialize in designing and developing custom finishing solutions. Committed to provide precious metal casting solutions, coin minting solution, platinum, gold and silver jewellery casting solution, bonding wire making solution, etc.

Hasung is looking for partners and investors for precious metals to develop technological innovation bringing outstanding return on investment.

We are a company who only makes high end quality equipment, we don't take price as priority, we take value for customers.