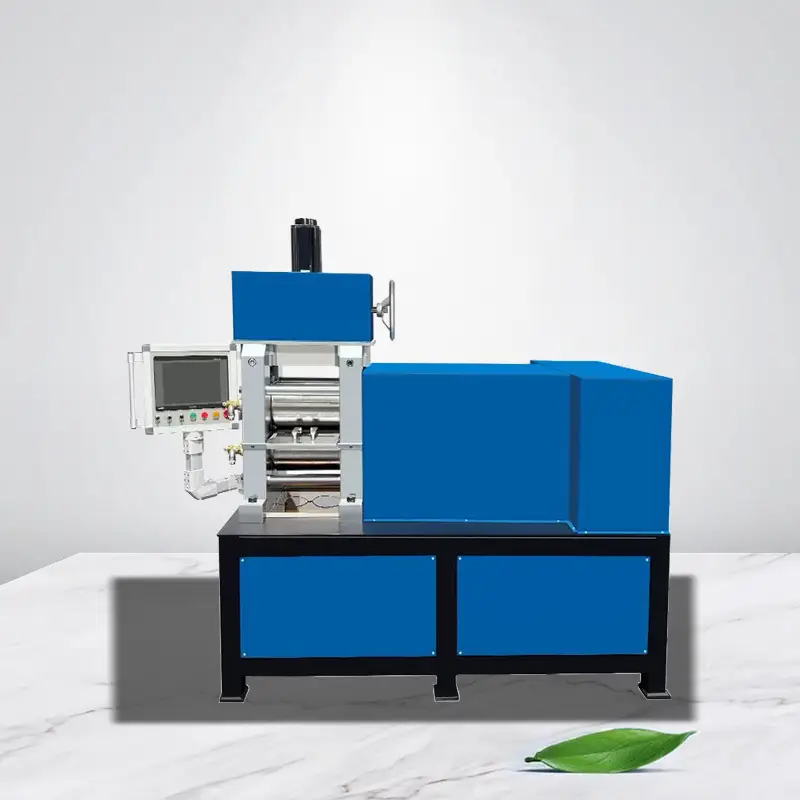

Quality 25HP Metal Rolling Mill with Servo Motor PLC Touch Screen Control Manufacturer | Hasung

The precious metal CNC rolling mill is a high-precision device specifically used for processing precious metal materials.

Model No.: HS-25HP

Product Introduction

I. Working Principle

The machine processes precious metal materials through a series of rollers.

The CNC system precisely controls the pressure,, and gap of the rollers, ensuring the stability and accuracy of the processing.

II. Main Features

1. High Precision: It can achieve very small sizeances, ensuring the quality of precious metal products.

2. High Automation: The CNC system can achieve automated operation, reducing human intervention and increasing production efficiency.

3 Good Stability: It uses high-quality mechanical structures and control systems to ensure the equipment remains stable during long hours of operation.

4. Strong Adaptability: It can precious metal materials of different shapes and sizes, meeting various production needs.

III. Application Fields

1. Jewelry Industry: It is used to process precious metal materials as gold, silver, and platinum for making various exquisite jewelry.

2. Electronics Industry: It processes conductive precious metal materials for the manufacture of electronic components.

3. Aerospace Field: It manufactures precious metal parts to meet the requirements of special environments such as high temperature and high pressure.

In summary, the CNC rolling mill for metals plays an important role in the field of precious metal processing. Its features of high precision, automation, and stability provide a reliable guarantee for the production of precious products.

Technical data:

| MODEL NO. | HS-25HP |

| Voltage | 380V, 50Hz 3 phases |

| Main Motor Power | 18.75KW |

| Servo motor power | 1.5KW |

| Roller material | Cr12MoV |

| Hardness | Hardness |

| Max. Input Sheet Thickness | 38mm |

| Roller size | φ205x300mm |

| Water cooling for roller | Optional |

| Machine size | 1800×900×1800mm |

| Weight | Approx. 2200kg |

Product Information

Company Advantages

Frequently Asked Questions about wire bonding machine

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115