Yuav ua li cas ci ci Golden Bar?

Yuav ua li cas cov tsoos kub ua? Zoo li cas!

Kev tsim cov khoom kub tseem yog qhov tshiab rau cov neeg feem coob, ib yam li kev paub tsis meej. Yog li, lawv ua li cas? Ua ntej, yaj cov hniav nyiaj hniav kub los yog kub mine kom tau cov khoom me me.

1. Ncuav cov kua kub kub rau hauv pwm.

2. Cov kub hauv pwm maj mam solidifies thiab ua ib qho khoom.

3. Tom qab cov kub tau ruaj khov lawm, tshem cov kub nugget ntawm pwm.

4. Tom qab tshem tawm cov kub, muab tso rau hauv qhov chaw tshwj xeeb kom txias.

5. Thaum kawg, siv lub tshuab kos tus lej, qhov chaw ntawm lub hauv paus chiv keeb, purity thiab lwm yam ntaub ntawv nyob rau hauv lem.

6. Qhov kawg tiav kub bar muaj purity ntawm 99.99%.

7. Cov neeg ua haujlwm ntawm no yuav tsum raug cob qhia kom tsis txhob squint, ib yam li tus kws qhia nyiaj txiag.

8. Kub tuav, tseem hu ua kub tuav, kub tuav, thiab kub ingots, yog bar-zoo li cov khoom ua los ntawm refined kub, uas feem ntau yog siv los ntawm cov tsev txhab nyiaj los yog cov tub lag luam los khaws cia, hloov mus, luam thiab peev. Nws tus nqi nyob ntawm qhov purity thiab zoo ntawm cov kub uas muaj.

9. Raws li Wikipedia, lub ntiaj teb loj tshaj plaws kub bar yog 250 kilograms, qhov ntev ntawm 45.5 cm ntev, 22.5 cm dav, 17 cm siab, thiab ib tug trapezoid inclined ntawm lub kaum sab xis ntawm 5 degrees. Raws li lub Rau Hli 19, 2017, nws tus nqi yog kwv yees li 10.18 lab US dollars.

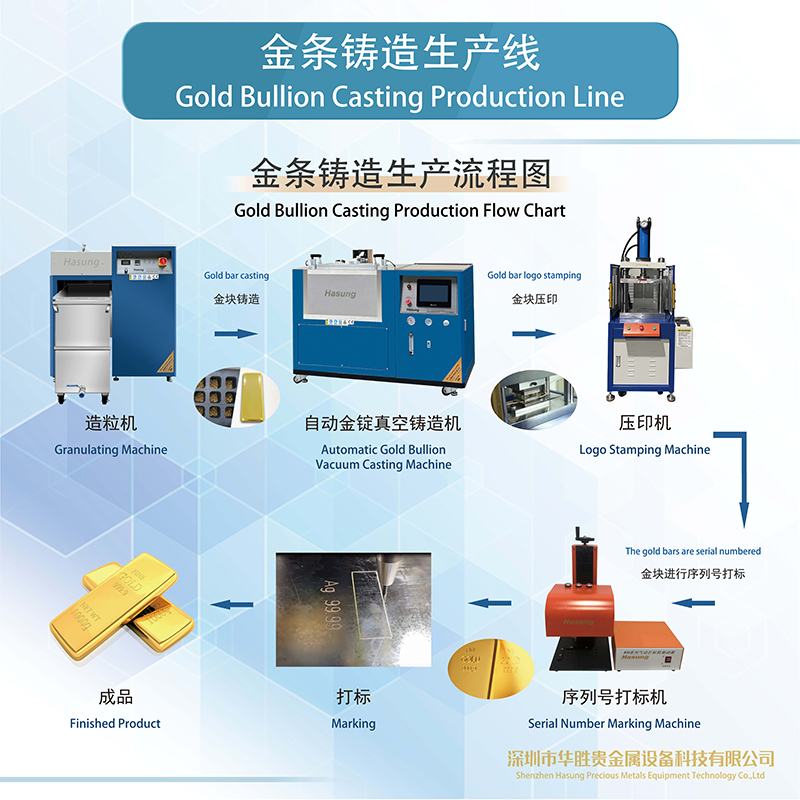

10. Niaj hnub no Kub Bar Casting

11. Kub bullion yog ib daim ntawv irreplaceable ntawm precious hlau rau lub lag luam. Txawm hais tias nws siv los ua cov khoom siv raw, cov khoom lag luam peev, lossis tus nqi cia, nws lub luag haujlwm tseem ceeb heev.

12. Hais txog yuav ua li cas ua kub tuav, muaj ob hom, tsoos kub bar casting txoj kev thiab nqus kub bar casting txoj kev.

13. Cov txheej txheem kub ib txwm ua yog siv dav tshaj plaws, feem ntau pom muaj nyob hauv cov miners lossis cov tuam txhab mining. Kub tuaj yeem ua kom huv los ntawm cua kub kub mus rau qhov kub thiab txias thiab tig mus rau hauv cov kua, ntxiv cov flux tsim nyog. Tom qab tshem tawm impurities, cov kua kub yog ncaj qha mus rau hauv pwm thiab txias rau tuav. Tom qab cov kub txias thiab zoo li tus, siv lub hydraulic xovxwm rau lub logo thiab thaws lub kub nuggets. Cov khoom kub zoo li no tuaj yeem siv rau kev lag luam.

14. Lub tshuab nqus tsev kub yog feem ntau ua nyob rau hauv lub refinery vim hais tias lawv feem ntau yuav tsum tau tsim kub bullion nrog zoo heev nto zoo thiab ci heev. Cov neeg feem ntau nyiam yuav cov kub zoo li no. Thaum lub refining tiav lawm, cov kub yog muab tso rau hauv ib tug granulator, los ntawm uas nws yog ua rau me me granules rau hnyav. Muab cov granules kub tso rau hauv lub pwm pwm, thiab thaum kawg muab cov pwm tso rau hauv lub tshuab nqus tsev casting tshuab. Nyob rau hauv kev tiv thaiv ntawm lub tshuab nqus tsev thiab inert gas, nws muaj peev xwm zam kub oxidation, shrinkage, thiab dej ripples ntawm qhov chaw. Tom qab casting, tso lub kub nugget nyob rau hauv lub logo stamping tshuab los nias tawm cov qauv thiab cov ntawv yuav tsum tau. Tom qab ntawd siv dot peen marking tshuab los suav cov kub tuav.

Hasung's Latest Nqus Kub Bars Ua Tshuab

Kauj Ruam 1: Smelt rau cov kub ntshiab.

Kauj Ruam 2: Ua cov granules kub los yog ua cov hmoov kub.

Kauj Ruam 3: Qhov hnyav thiab casting kub tuav nrog lub tshuab ingot.

Kauj Ruam 4: Stamping logos ntawm cov kub tuav.

Kauj Ruam 5: Dot peen naj npawb npav tshuab los kos cov lej cim.

Cov txiaj ntsig ntawm Kev Siv Hasung Tsis Siv Neeg Kub Bar Nqus Casting Tshuab

Puas yog koj nyob hauv kev lag luam ntawm kev tsim cov khoom kub zoo? Yog tias muaj, koj nkag siab qhov tseem ceeb ntawm precision thiab efficiency nyob rau hauv cov txheej txheem casting. Qhov no yog qhov twg Hasung Tsis Siv Neeg Kub Bar Nqus Casting Tshuab los ua si. Featuring tag nrho tsis siv neeg ua haujlwm thiab ib qho yooj yim-rau-siv tsim, lub tshuab no muaj ntau yam zoo uas tuaj yeem txhim kho koj cov txheej txheem ntau lawm. Nyob rau hauv no blog, peb yuav tshawb txog qhov zoo ntawm kev siv Hasung tsis siv neeg kub bar nqus tsev casting tshuab thiab yuav ua li cas nws yuav pab tau koj cam khwb cia zoo nkauj ci kub tuav nrog daim iav zoo li nto.

1. High-quality kub ingots

Hasung lub siab tsis siv neeg kub lub tshuab nqus tsev casting tshuab ua haujlwm nyob rau hauv lub tshuab nqus tsev thiab inert gas, kom ntseeg tau tias cov khoom kub zoo. Los ntawm kev tshem tawm cov huab cua thiab lwm yam shrinkage thaum lub sij hawm casting txheej txheem, lub tshuab ua cov kub tuav nrog tshwj xeeb purity thiab kev ntseeg siab. Qhov no yog qhov tseem ceeb rau kev tsim cov khoom kub uas ua tau raws li cov qauv kev lag luam siab tshaj plaws thiab ua tau raws li cov kev xav tau ntawm cov neeg siv khoom zoo.

2. Tsis siv neeg ua haujlwm siab

Ib qho ntawm cov yam ntxwv zoo ntawm Hasung tsis siv neeg kub lub tshuab nqus tsev casting yog nws cov haujlwm tsis siv neeg. Qhov no txhais tau hais tias tag nrho cov txheej txheem casting los ntawm kev thauj khoom raw mus rau ejecting tiav cov khoom kub yog seamlessly automated. Raws li qhov tshwm sim, koj tuaj yeem txo qhov xav tau ntawm phau ntawv kev cuam tshuam, yog li ua kom muaj txiaj ntsig thiab sib xws ntawm koj cov haujlwm ntau lawm.

3. Yooj yim rau siv

Txawm hais tias nws cov yam ntxwv siab heev, Hasung tsis siv neeg kub lub tshuab nqus tsev casting yog tsim los siv tau yooj yim. Nws intuitive interface thiab kev tswj yooj yim ua rau nws yooj yim rau cov neeg ua haujlwm teeb tsa thiab khiav lub tshuab nrog kev cob qhia tsawg. Tsuas yog yuav tsum tau teeb tsa lub sijhawm cua sov thiab lub sijhawm txias nrog lub zog. Qhov yooj yim ntawm kev siv no tsis tsuas yog ua kom yooj yim rau cov txheej txheem ntau lawm, nws kuj txo qhov ua yuam kev lossis tsis sib xws hauv cov txheej txheem kub kub casting.

4. Txhim khu kev ruaj ntseg

Kev khiav hauj lwm nyob rau hauv lub tshuab nqus tsev thiab inert gas tej yam kev mob tsis tsuas yog pab txhim kho qhov zoo ntawm cov kub tuav, tab sis kuj ua rau kom muaj kev ruaj ntseg ntawm cov txheej txheem casting. Los ntawm kev txo qis qhov muaj roj inert thiab lwm cov roj reactive, tsis muaj kev pheej hmoo ntawm hluav taws kub lossis lwm yam xwm txheej txaus ntshai tshwm sim. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog thaum ua haujlwm nrog cov hlau muaj txiaj ntsig xws li kub, qhov chaw ruaj ntseg thiab kev tswj hwm kev pheej hmoo yog qhov kev txhawj xeeb tseem ceeb.

5. Daim iav kub tuav

Hasung tsis siv neeg kub bar nqus tsev casting tshuab muaj peev xwm ua tau daim iav kub tuav. Qhov no txhais tau hais tias qhov tiav kub bar nthuav tawm cov nyhuv zoo kawg nkaus, txhim kho nws qhov kev pom zoo. Txawm hais tias koj tab tom tsim kev nqis peev-qib kub tuav lossis cov khoom zoo nkauj, lub peev xwm ua tiav cov qib siab ntawm qhov zoo tuaj yeem ua rau koj cov khoom muag hauv khw.

6. Cov txiaj ntsig zoo ib yam

Kev sib raug zoo yog qhov tseem ceeb hauv kev tsim khoom kub, tshwj xeeb tshaj yog thaum nws los ua kom tau raws li cov kev xav tau ntawm cov neeg siv khoom zoo. Hasung tsis siv neeg kub lub tshuab nqus tsev casting tshuab xa cov txiaj ntsig zoo ib yam, kom ntseeg tau tias txhua qhov kub tau ua tau raws li cov qauv teev tseg ntawm qhov hnyav, purity thiab nto tiav. Qib no ntawm precision thiab rov ua dua yog qhov tseem ceeb rau kev tsim kev ntseeg siab thiab kev ntseeg siab ntawm cov neeg siv khoom.

7. Txo cov khoom pov tseg

Kev ua tau zoo hauv cov txheej txheem casting tsis tsuas yog txhais tau tias txuag lub sijhawm, tab sis kuj pab txo cov khoom pov tseg. Hasung tsis siv neeg kub lub tshuab nqus tsev casting tshuab yog tsim los ua kom zoo dua kev siv cov khoom siv raw, txo qis tshaj, thiab xyuas kom meej tias cov khoom kub kub yog cov peev txheej zoo li sai tau. Qhov no tuaj yeem muaj txiaj ntsig zoo rau koj cov nqi khiav lag luam thiab ib puag ncig hneev taw.

8. Ntau yam

Thaum lub hom phiaj tseem ceeb ntawm Hasung Tsis Siv Neeg Kub Bar Nqus Casting Tshuab yog kub bar ntau lawm, nws versatility kuj tso cai rau cov casting ntawm lwm yam hlau muaj nuj nqis. Txawm hais tias koj tab tom ua haujlwm nrog cov nyiaj, platinum (customized) lossis lwm yam khoom muaj txiaj ntsig zoo, lub tshuab no tuaj yeem hloov kho rau ntau yam ntaub ntawv, ua rau nws muaj txiaj ntsig zoo hauv kev sib txawv ntawm koj cov khoom.

9. Kev ua haujlwm yooj yim

Hasung Tsis Siv Neeg Kub Bar Nqus Casting Tshuab pab txhim kho kev ua haujlwm los ntawm kev ua haujlwm ntawm cov txheej txheem casting thiab kev sib koom ua ke ntawm lub tshuab nqus tsev thiab cov roj inert. Qhov no txhais tau tias koj tuaj yeem txhim kho kev npaj ntau lawm, txo cov fwj thiab ua kom cov khoom zoo sib xws ntawm cov khoom kub zoo. Thaum kawg, qhov no ua rau muaj kev tsim khoom ntau dua thiab siv cov peev txheej zoo dua.

10. Kev nqis peev ntev

Kev nqis peev hauv Hasung tsis siv neeg kub lub tshuab nqus tsev casting yog ntau tshaj li qhov kev daws teeb meem luv luv rau koj cov kev xav tau ntau lawm. Nrog nws cov rugged kev tsim kho thiab cov cuab yeej siv siab heev, lub tshuab muaj peev xwm tiv taus qhov hnyav ntawm kev siv hauv kev lag luam thiab muab kev ua haujlwm ntev ntev. Los ntawm kev siv lub tshuab no rau hauv koj qhov chaw tsim khoom, koj tab tom ua ib qho kev nqis peev zoo rau yav tom ntej ntawm koj txoj kev lag luam.

Hauv luv luv, cov txiaj ntsig ntawm kev siv Hasung tsis siv neeg kub lub tshuab nqus tsev casting yog pom tseeb. Los ntawm lub peev xwm los tsim cov kub kub zoo nyob rau hauv lub tshuab nqus tsev thiab inert gas tej yam kev mob rau tag nrho cov tsis siv neeg ua hauj lwm thiab cov neeg siv-phooj ywg tsim, lub tshuab no muaj ntau yam zoo uas yuav coj koj kub bullion ntau lawm mus rau qhov siab tshiab. Txawm hais tias koj tab tom tsom mus rau kev ua tiav qhov zoo tshaj plaws, txhim kho kev sib raug zoo lossis ua kom koj cov haujlwm ua haujlwm zoo, Hasung tsis siv neeg kub lub tshuab nqus tsev casting yog ib qho khoom muaj nqis uas tuaj yeem pab txhawb koj txoj kev lag luam.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115