Minted Gold Bars Ua li cas?

Minted kub tuav yog ib txwm tsim los ntawm cam khwb cia kub tuav uas tau dov mus rau ib tug uniform thickness. Hauv cov ntsiab lus dav dav, cov yob cam khwb cia yog xuas nrig ntaus nrog tuag los tsim qhov khoob nrog qhov xav tau qhov hnyav thiab qhov ntev. Txhawm rau sau cov duab obverse thiab thim rov qab, cov blanks raug ntaus hauv lub minting xovxwm.

Minted tuav yog tsim los rau qhov ntev (zoo li npib). Lawv ib txwm tau raug cim nrog cov ntawv pov thawj ntawm tus neeg ua haujlwm lossis cov neeg tawm tswv yim, qhov hnyav tag nrho lossis cov ntsiab lus kub zoo thiab cov kub purity (feem ntau yog 999.9).

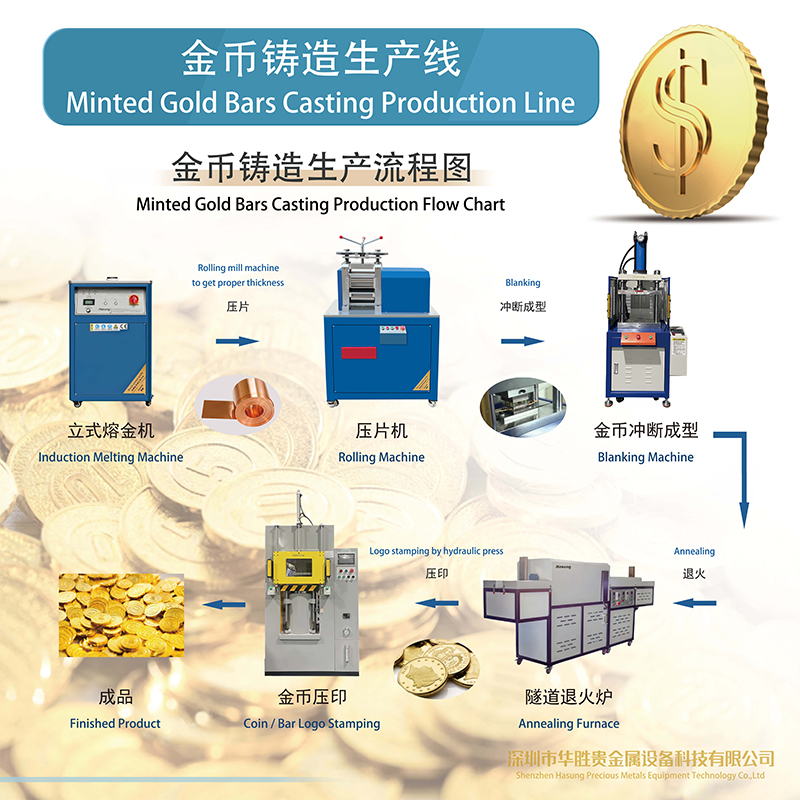

Minted kub tuav cov kab ntau lawm suav nrog:

1. Hlau melting / Nruam casting rau kev ua ntawv

2. Rolling mill tshuab kom tau raws li thickness

3. Annealing

4. Npib blanking los ntawm lub tshuab xovxwm

5. Polishing

6. Annealing, ntxuav nrog acids

7. Logo stamping los ntawm hydraulic xovxwm

Minted bar ntau lawm kab:

Thov hu rau peb rau cov lus hais ntawm kub tuav minting ntau lawm kab.

Whatsapp: 0086 17898439424

Email:sales@hasungmachinery.com

Qhov txawv ntawm Cast thiab Minted Gold Bars yog dab tsi?

Txij li thaum nws nrhiav tau ntau txhiab xyoo dhau los, cov txheej txheem ntawm refining kub thiab minting kub tuav tau txhim kho thiab hloov zuj zus ntau zaus. Qhov no tau muab qhov nruab nrab cov tub ua lag luam muaj ntau yam kev xaiv ntawm kub tuav nyob rau hauv cov nqe lus ntawm hom, qhov ntau thiab tsawg thiab hom.

Nyob ntawm cov txheej txheem tsim khoom, cov khoom kub tau muab faib ua ob hom - Kub Cast Bars thiab Minted Gold Bars. Hauv tsab ntawv blog no, peb yuav tham txog ob hom kub tuav thiab lawv qhov sib txawv.

Ntim: Minted kub tuav tau ntim ruaj ntseg thiab feem ntau yog ib feem tseem ceeb ntawm lawv cov nqi nyob ntawm lub ntim. Kev qhib lub ntim tuaj yeem ua rau txo qis ntawm cov tuav, tsis zoo li cov cam khwb cia uas koj tuaj yeem kov nrog koj txhais tes. Vim li no cov tub ua lag luam thiab cov neeg sau khoom feem ntau xav tias nws yog qhov tsis zoo ntawm minted tuav.

Kub Cast Bars

Lawv tseem hu ua 'poured' lossis 'molded' tuav thiab paub txog lawv cov txheej txheem tsim khoom ib txwm muaj. Lub pwm yog tsim ua ntej los xyuas kom meej tias cov kub tuav yog tsim los ntawm qhov loj me, cov duab, thiab qhov hnyav. Cov kub yog ces rhuab mus rau ib tug heev kub kom txog thaum nws ua kua thiab yog poured rau hauv pwm. Kub solidifies sai sai thiab thaum nws txias, nws raug tshem tawm ntawm pwm.

Cam khwb cia hlau yog ntuj saib dua li lwm hom khoom siv kub. Nws los nrog tsuas yog ib qho yooj yim engraving ntawm cov ntsiab lus ntawm lub kub bar thiab nws cov chaw tsim tshuaj paus. Lub engraving yog ua tiav nyob rau hauv ob peb teev tom qab noj cov kub los ntawm pwm.

Cov kab no muaj nyob rau hauv qhov hnyav sib txawv xws li 1 ooj, 2 ½ ooj, 5 ooj, 10 ooj, 20 ooj thiab 50 ooj.

Minted Kub Bars

Minted tuav (txiav los ntawm ib tug dov sawb ntawm kub), txawm li cas los, yog ib tug niaj hnub tshwm sim. Lawv tsuas yog tsim los ntawm ntau qhov ntau (feem ntau yog los ntawm LBMA-kev lees paub refiners) txij li xyoo 1970s.

Minted kub tuav yog nrov heev nrog cov tub ua lag luam. Lawv yog cov feem ntau paub kub bar hom nrog ci ntsa iab thiab zoo kawg nkaus huv si. Kev tsim cov txheej txheem ntawm minted kub tuav yog ob qho tib si siv sij hawm thiab kim dua kub cam khwb cia.

Thaum lub sij hawm thaum ntxov ntawm kev tsim minted kub tuav, lawv ib txwm ua tiav zoo li cam khwb cia tuav los ntawm lub tshuab compression kom muaj cov duab zoo thiab loj dua. Txawm hais tias cov txheej txheem no tseem siv, lub tshuab nruam nruam yog siv niaj hnub no los ua cov pob zeb kub. Qhov hnyav thiab qhov loj ntawm txhua qhov ntawm cov kab no raug tshuaj xyuas kom zoo thiab tag nrho cov khoom tsis zoo yog muab tso rau hauv lub qhov cub loj kom muag lawv thiab ntaus lawv rov qab mus rau qhov zoo.

Cast Bars Vs Minted Bars

Sib nrug los ntawm qhov sib txawv ntawm lawv cov txheej txheem tsim khoom, kub cam khwb cia thiab minted kub tuav kuj muaj qhov sib txawv zoo thiab qhov tsis zoo.

Cov tsos mob: Cov txheej txheem casting, txawm tias yooj yim, tsim tshwj xeeb irregularities, ruggedness, thiab blemishes ntawm ib tug neeg cam khwb cia. Lawv kuj yog me ntsis ntxhib ntawm cov npoo. Tsis muaj ob qho tib si. Minted kub tuav, ntawm qhov tod tes, raug txiav los ntawm ib txoj hlua ntev ntawm cov hlau ua tiav uas tshem tawm qhov muaj feem ntawm cov cim lossis qhov tsis zoo.

Nqe: Raws li cov txheej txheem casting yog pheej yig dua li lwm cov txheej txheem tsim, cov cam khwb cia kub muaj nyob rau ntawm tus nqi qis. Lawv zoo tagnrho rau cov tub ua lag luam tab tom nrhiav kom them tus nqi qis tshaj ntawm cov nqi kub. Minted kub tuav feem ntau muaj nyob rau ntawm tus nqi siab dua vim tias lawv cov txheej txheem tsim khoom kim heev.

Ntim: Minted kub tuav tau ntim ruaj ntseg thiab feem ntau yog ib feem tseem ceeb ntawm lawv cov nqi nyob ntawm lub ntim. Kev qhib lub ntim tuaj yeem ua rau txo qis ntawm cov tuav, tsis zoo li cov cam khwb cia uas koj tuaj yeem kov nrog koj txhais tes. Vim li no, cov tub ua lag luam thiab cov neeg sau khoom feem ntau xav tias nws yog qhov tsis zoo ntawm minted tuav.

Muag Kub: Yog tias koj xav muag koj cov kub rau nyiaj ntsuab, minted bars yooj yim dua rau muag dua li cov cam khwb cia. Qhov no yog vim lawv qhov zoo tshaj plaws hauv qhov loj me, cov duab thiab tsim dua kub cam khwb cia.

Txhua yam ntawm cov khoom kub no yog siv rau lub hom phiaj sib txawv. Kub cam khwb cia, txawm tias nrov heev ntawm cov neeg sau khoom thiab cov tub ua lag luam rau lawv cov xwm txheej, feem ntau paub tias muaj qhov tsawg kawg nkaus rov qab los ntawm kev nqis peev. Minted tuav yog kim kim tab sis lawv muaj nqi zoo dua. Koj yuav tsum txiav txim siab txog koj qhov kev nqis peev kub raws li koj xav siv lawv li cas.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115