6KG Silver Granulating Machine - Induction Melting Furnace

Product features

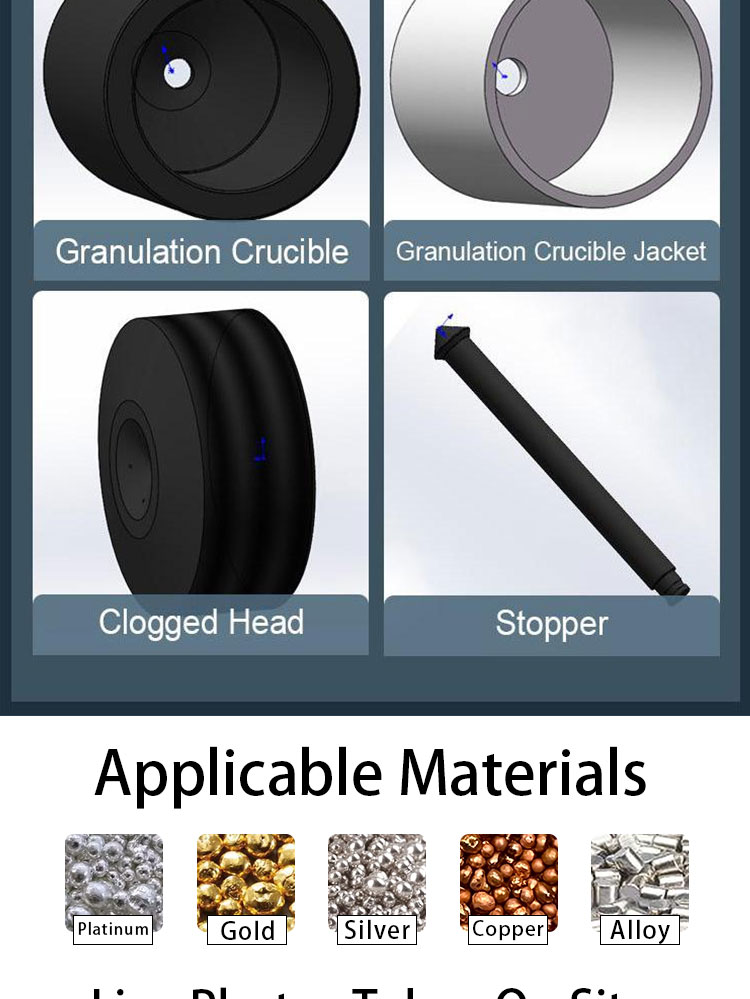

The 6KG Silver Granulating Machine - Induction Melting Furnace offers precise temperature control with an accuracy of up to ±1°C, ensuring optimal casting results. This machine is equipped with imported Mitsubishi controller, ensuring reliability and efficiency in operation. With IGBT advanced heating technology, the casting effect is excellent, offering stability, safety, and optional capacity for molten gold, making it ideal for various applications in Jewelry Tools & Equipment.

Team strength

At the core of our 6KG Silver Granulating Machine is a team of skilled professionals who work tirelessly to ensure its exceptional performance and reliability. Our team's expertise in induction melting technology and precision engineering enables us to deliver a top-quality product that meets the demands of even the most discerning customers. With a focus on innovation and continuous improvement, our team is dedicated to pushing the boundaries of what is possible in the field of granulating machines. Trust in our team's strength to provide you with a product that will exceed your expectations and deliver exceptional results every time.

Enterprise core strength

The 6KG Silver Granulating Machine - Induction Melting Furnace stands out for its exceptional team strength. With a robust construction and advanced technology, this machine has been designed and optimized by a team of skilled engineers and technicians. Their collective expertise ensures high performance, precision, and durability. The seamless collaboration within the team has resulted in a reliable and efficient product, perfect for industrial applications. Customers can trust in the team strength behind this machine to deliver consistent results, making it a valuable investment for any business looking to enhance their melting and granulating processes.

Shenzhen Hasung Precious Metals Equipment Co., Ltd grasp the new market trends, insight into the actual needs of customers, relying on advanced production technology and accurate market positioning, successfully launched Factory Supply 6KG Silver Granulating Machine For Gold Silver Copper Alloys. Through the application of technology, Shenzhen Hasung Precious Metals Equipment Co., Ltd have mastered the most efficient and labor-saving method to manufacture the product.It is its wide and effective performance that contributes to its wide uses in the application fields of Jewelry Tools & Equipment. Influenced by the market trends and customers' requirements, the design of Precious Metals Melting Equipment, Precious metals casting machine, gold bar vacuum casting machine,gold silver granulating machine,precious metals continuous casting machine,gold silver wire drawing machine, vacuum induction melting furnace,precious is made to be unique. It adopts the raw materials that have been tested to conform to the quality standards, which guarantees its quality from the source.

2.Easy operation

3.Use imported Mitsubishi controller.

4.Silver Granulator with temperature control (Gold Silver Grains Casting Machine, Silver Granulating Machine).

5.This machine adopts IGBT advanced heating technology, the casting effect is very good,

the system is stable and safe, molten gold capacity is optional, and the granulated metal specification is optional.

6.The granulation speed is fast and no noise. Perfect advanced testing and protection functions make the whole machine safe and durable.

7.The machine has a split design and the body has more free space.

MODEL NO. | HS- GS3 | HS- GS6 | HS- GS8 |

Voltage | 220V, 50/60Hz | 380V, 50/60Hz | |

power | 8KW | 15KW | 20KW |

capacity | 3kg (Gold) | 6kg (Gold) | 8kg (Gold) |

Max. Temperture | 1500°C | ||

Temp Accuracy | ± 1°C; | ||

Application | Gold, Silver, Copper, alloys | ||

Dimensions | 110*980*1340mm | ||

Features | With temperature control, accuracy up to ±1°C. With argon protection, lifetime of crucible will be longer. Saving cost.Apply Germany technology, imported parts | ||

Weight | approx. 150kg | approx. 180kg | |

Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||

Cooling type | Water chiller(sold separately) or Running water | ||

Packing&Shipping Payment

Patents and certificates

casting equipment, especially for high tech vacuum and high vacuum casting machines.

A: Two years warranty.

machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115