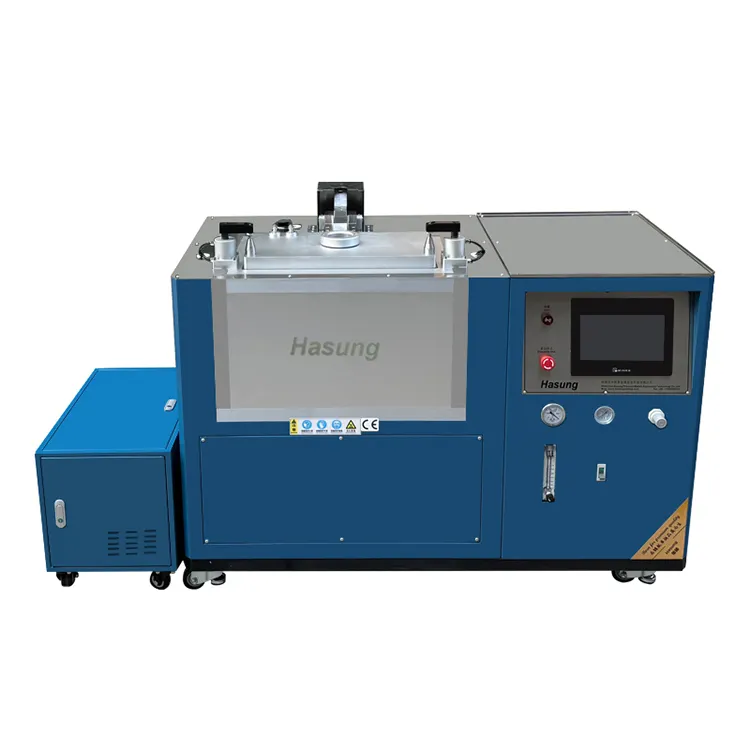

Automatic Gold Bar Casting Machine: Precision & Efficiency

Product features

The vacuum silver ingot casting machine is a technologically advanced solution for precise and efficient gold bar production. With automated operation and state-of-the-art features, this machine ensures flawless casting results, delivering sparkling gold bars of the highest quality. Designed for modern gold refining processes, this machine offers user-friendly controls, durability, and safety features, making it a valuable asset for businesses looking to enhance their production capabilities and meet industry standards.

Team strength

Our team at Automatic Gold Bar Casting Machine is our greatest strength. Comprised of skilled engineers, designers, and technicians, we collaborate seamlessly to ensure the precision and efficiency of our state-of-the-art casting machine. With a shared passion for innovation and dedication to quality, our team works tirelessly to deliver a high-performing product that meets the needs of our customers. Trust in our expertise and experience to provide you with a reliable and cutting-edge solution for all your gold bar casting needs. Choose Automatic Gold Bar Casting Machine for a product that is backed by a team you can count on.

Enterprise core strength

At Automatic Gold, our team strength lies in our unparalleled precision and efficiency when it comes to producing high-quality gold bars. Our skilled technicians work seamlessly together to ensure that each gold bar casting machine is meticulously crafted and tested for optimum performance. With a focus on innovation and reliability, our team is constantly pushing the boundaries of technology to provide our customers with the best possible product. Trust in our team's expertise and dedication to deliver top-of-the-line gold bar casting machines that exceed your expectations. Experience the difference with Automatic Gold.

Key Features:

1.Fully Automatic Operation:

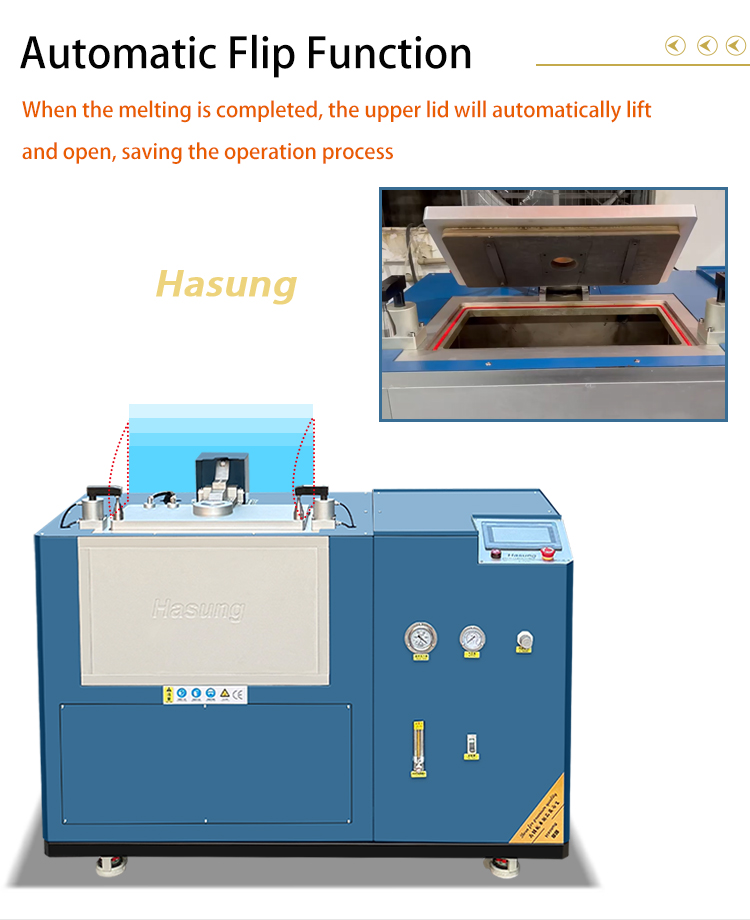

One-touch control for melting, pouring, and cooling cycles.

Reduces labor costs and minimizes human error.

2.Vacuum Casting Technology:

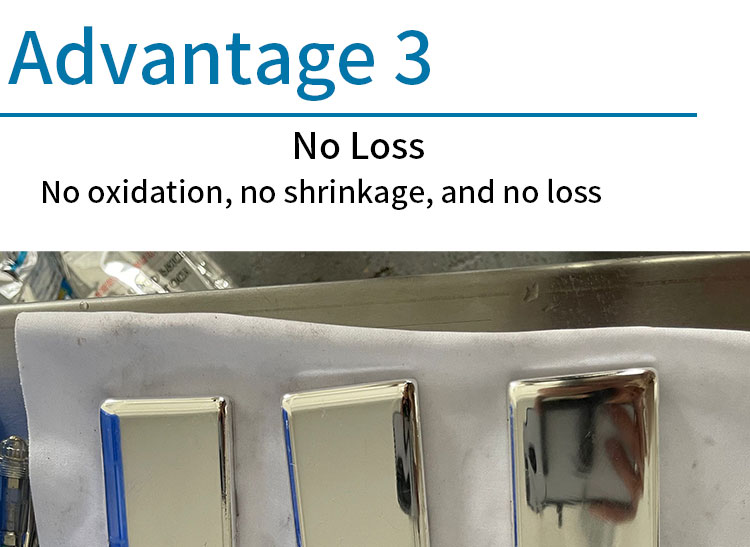

Eliminates oxidation and impurities, ensuring high-purity gold bars.

Ideal for 999.9 fine gold (24K) casting.

3.Precision Temperature Control:

±1°C accuracy with PID-controlled heating system.

Ensures uniform melting and pouring.

4.Energy-Efficient Design:

Optimized heating cycles reduce power consumption.

5.Intelligent Control System:

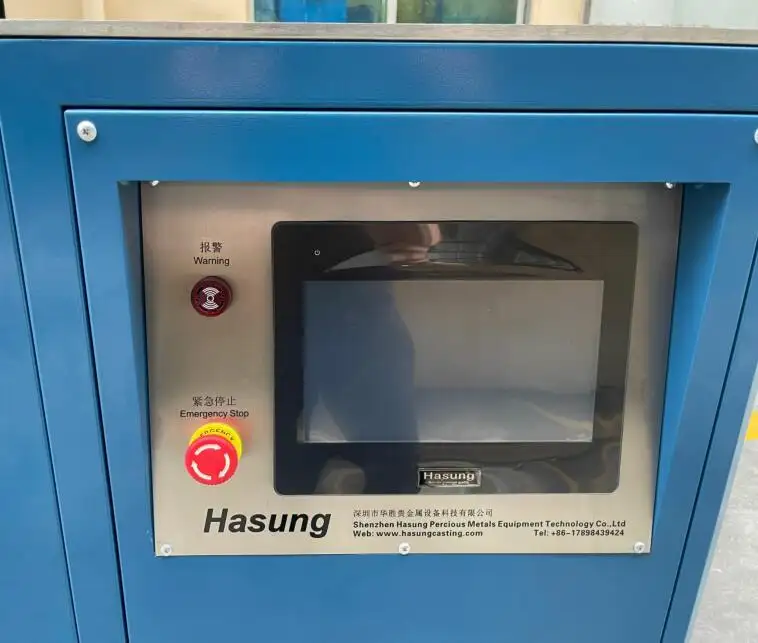

PLC-based touchscreen panel for precise parameter setting and real-time monitoring.

Structure & Components:

Vacuum Chamber: Hermetically sealed stainless steel construction with dual-layer insulation.

Induction Heating System: High-frequency induction coil for rapid and uniform melting.

Mold & Pouring Mechanism: Tilting system for precise metal pouring under vacuum.

Intelligent Control Panel: Real-time data logging for traceability and quality control.

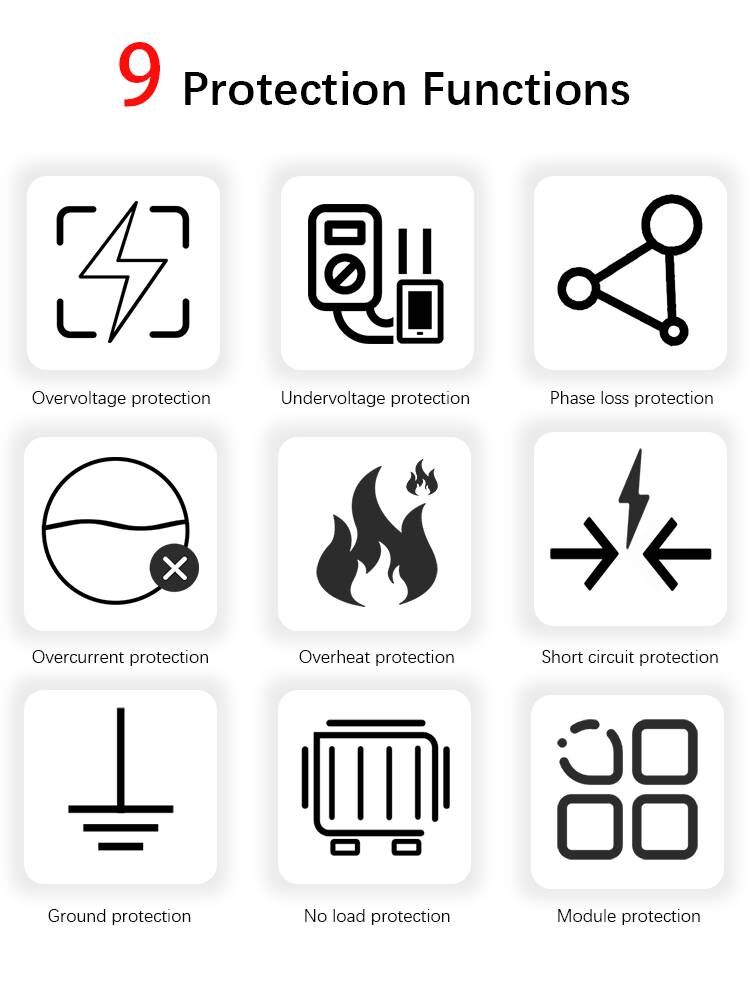

Safety Features: Overheat protection, emergency stop, and vacuum leak detection.

Technical Secifications:

Gold Bar Making Machine / Vacuum Gold Ingot Casting Machine with 10" PLC Display controller system.

| Model No. | HS-GV4 |

| Voltage | 380V ,50/60Hz 3 Phases |

| Power | 50KW |

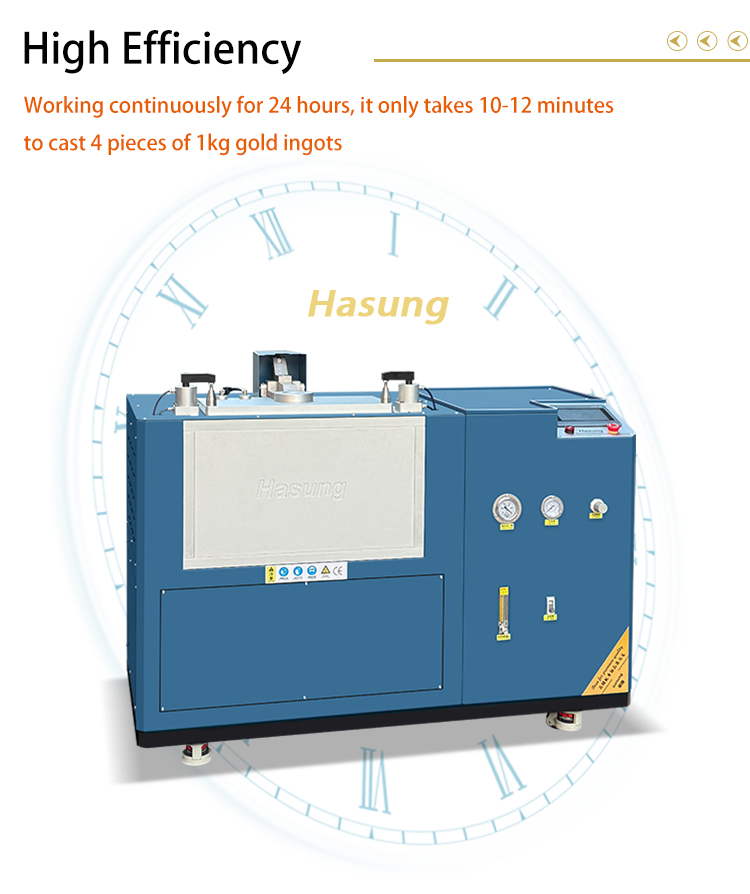

| Casting cycle time | 10-12 min. |

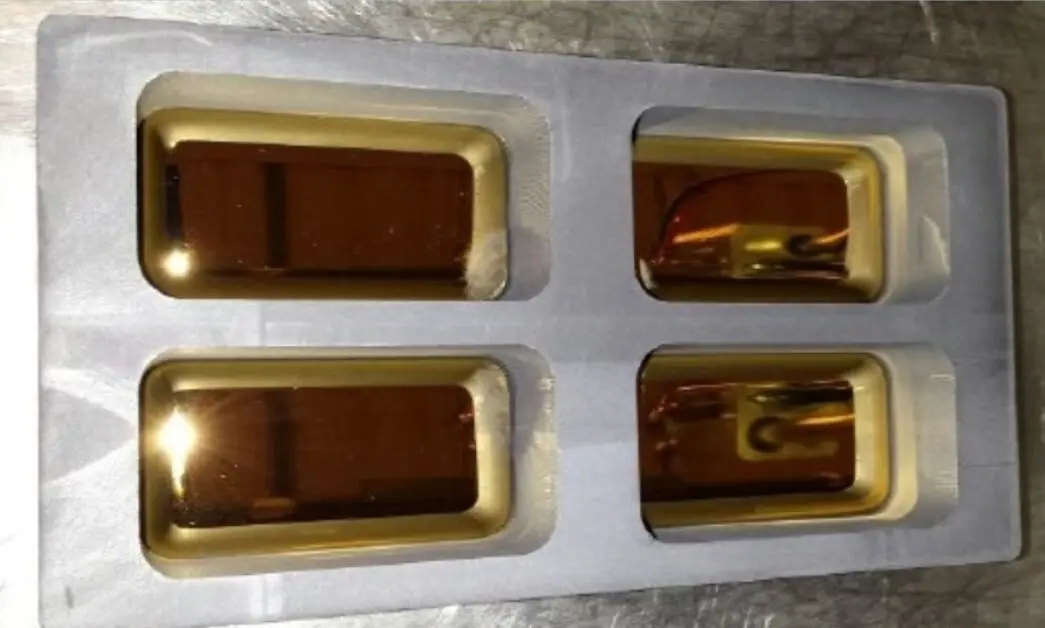

| Capacity (Au) | 4kg (4 pcs 1kg, 16pcs 100g or more.) |

| Max Temperature | 1500°C |

| Application metals | Gold, Silver |

| Inert gas | Argon / Nitrogen |

| Water Cooling Temperature | 20-26°C |

| Vacuum pump | High performance value vacuum pump (included) |

| Operation method | One key operation to finish the entire casting process |

| Cooling type | Water chiller(sold separately) or Running water |

| Controller system | 7" Siemens touch screen + Siemens PLC control system |

| Dimensions | 1460*720*1010mm |

| Weight | approx. 380kg |

Advantages:

Hasung automatic gold bar casting machine equipped with state-of-the-art technology, this state-of-the-art machine offers fully automated operation for seamless and efficient gold bar casting. With its precision engineering and cutting-edge features, the machine delivers flawless casting results, producing sparkling, flawless gold bars of the highest quality.

1.The automatic gold casting machine is designed to meet the needs of modern gold refining and manufacturing processes. Its automated operation streamlines the casting process, eliminating the need for manual intervention and ensuring consistent and precise results every time. This not only increases productivity but also reduces the margin of error, making it an indispensable tool for gold bullion production facilities.

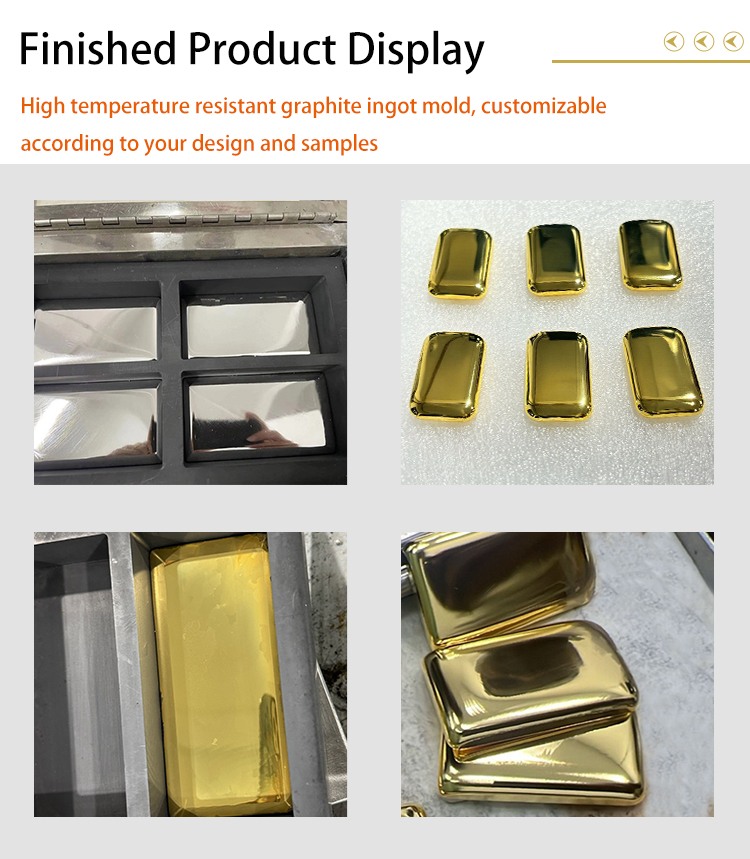

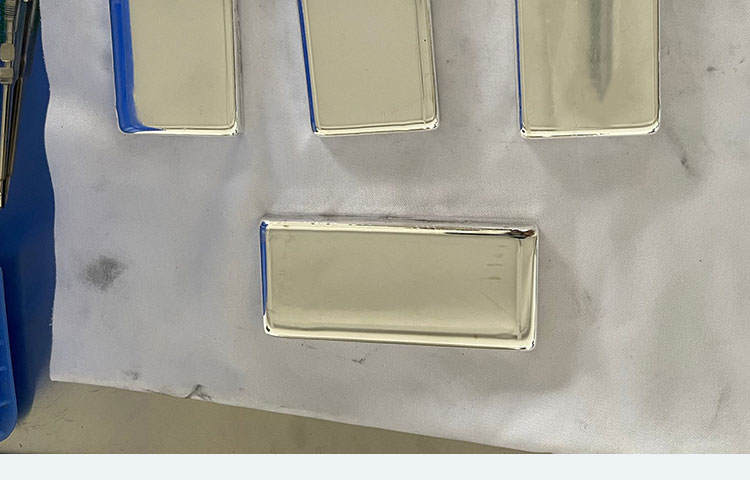

2.One of the main highlights of this gold casting furnace is its ability to produce shiny gold bars with excellent surface finish. Advanced casting technology ensures that the gold bars are free from defects such as bubbles or surface irregularities, resulting in a pristine and lustrous apearance. This level of quality is critical to meeting the exacting standards of the gold industry and meeting the expectations of discerning customers.

3.The automatic gold vacuum casting machine is designed to provide a user-friendly experience, with intuitive controls and a user interface that simplifies operation. Its automated features, including precise temperature control and casting parameters, can be easily programmed and monitored, allowing operators to easily oversee the entire casting process. This not only improves operational efficiency but also minimizes the need for extensive training, making it accessible to a wide range of users.

4.The machine is designed with durability and reliability in mind. It's built with high-quality materials and components to withstand the rigors of continuous operation, ensuring long-term performance and minimal downtime. This robust construction coupled with strict quality control measures ensures that the automatic gold molding machine delivers consistent and reliable results that meet the demands of high-volume production environments.

How It Works:

Pre-Casting Preparation:

Gold is placed in a graphite or ceramic mold within the vacuum chamber.

Chamber is sealed, and vacuum pump removes oxygen to prevent oxidation.

Melting & Pouring:

High-frequency induction heating melts gold within 10-15 minutes (4KG model).

Vacuum pouring ensures no air bubbles or impurities.

Cooling & Demolding:

Built-in cooling system accelerates solidification, while automated demolding ensures bar integrity.

Applications:

1.Gold Refining: Standardized bullion production for banks, mints, and bullion dealers.

2.Jewelry Manufacturing: Custom gold bar casting for high-end jewelry brands.

3.Research & Education: Used by universities and research institutions for material testing and demonstrations.

FAQ:

Q1. What makes the HS-GV4 ideal for gold/silver bar production?

A1: High Precision: 10" PLC touchscreen (Weinview/Siemens) ensures accurate temperature control (up to 1,500°C).

Fast Cycle Time: Casts 4kg of gold (4x1kg bars or 16x100g bars) in 10–12 minutes.

Vacuum Casting: Eliminates porosity for flawless bullion quality.

Inert Gas Protection: Uses argon/nitrogen to prevent oxidation during casting.

Q2. How does the gold bar making machine simplify the casting process?

A2: One-Key Operation: Automates melting, pouring, and cooling for error-free production.

High-Performance Vacuum Pump: Ensures consistent vacuum levels for defect-free bars.

PLC Control: Adjusts parameters (temperature, cycle time) via touchscreen for different alloys.

Q3. What metals can the HS-GV4 process?

A3: Precious Metals: Gold (24K, 22K, 18K), silver (sterling, fine).

Optional Customization: Adaptable for platinum/palladium (contact for specs).

Q4. How does the HS-GV4 compare to manual casting?

A7: Consistency: Eliminates human error for uniform bar weight/purity.

Cost-Efficient: Lowers labor costs and material waste.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115