Automatic Gold Bullion Casting Machine

Product advantages

The Automatic Gold Bullion Casting Machine offers unparalleled precision and efficiency in casting gold bullion, ensuring each piece is flawless and of the highest quality. Its advanced technology allows for easy operation and customization, making it ideal for both small-scale and large-scale production. With its durable construction and reliable performance, this machine is an indispensable tool for any jewelry manufacturer or goldsmith looking to elevate their production process.

We serve

At our core, we serve as innovators in the precious metals industry, offering an Automatic Gold Bullion Casting Machine that revolutionizes the manufacturing process. Our advanced technology and superior craftsmanship ensure precise and efficient casting, producing high-quality gold bullion with ease. Additionally, we serve our customers by providing exceptional support and guidance, helping them maximize their production capabilities and achieve their business goals. With a commitment to excellence and dedication to customer satisfaction, we strive to serve as a trusted partner in the success of our clients, setting new standards in the industry.

Enterprise core strength

At our core, we serve excellence in quality and precision with our Automatic Gold Bullion Casting Machine. Our state-of-the-art technology ensures flawless casting every time, allowing for the creation of high-quality gold bullion with ease. We also serve convenience and efficiency, as our machine automates the casting process, saving time and labor costs for our customers. Additionally, we serve innovation and reliability, as our machine is designed to be easy to operate and maintain, ensuring consistent results. Trust us to serve your gold casting needs with the highest standards of quality and efficiency.

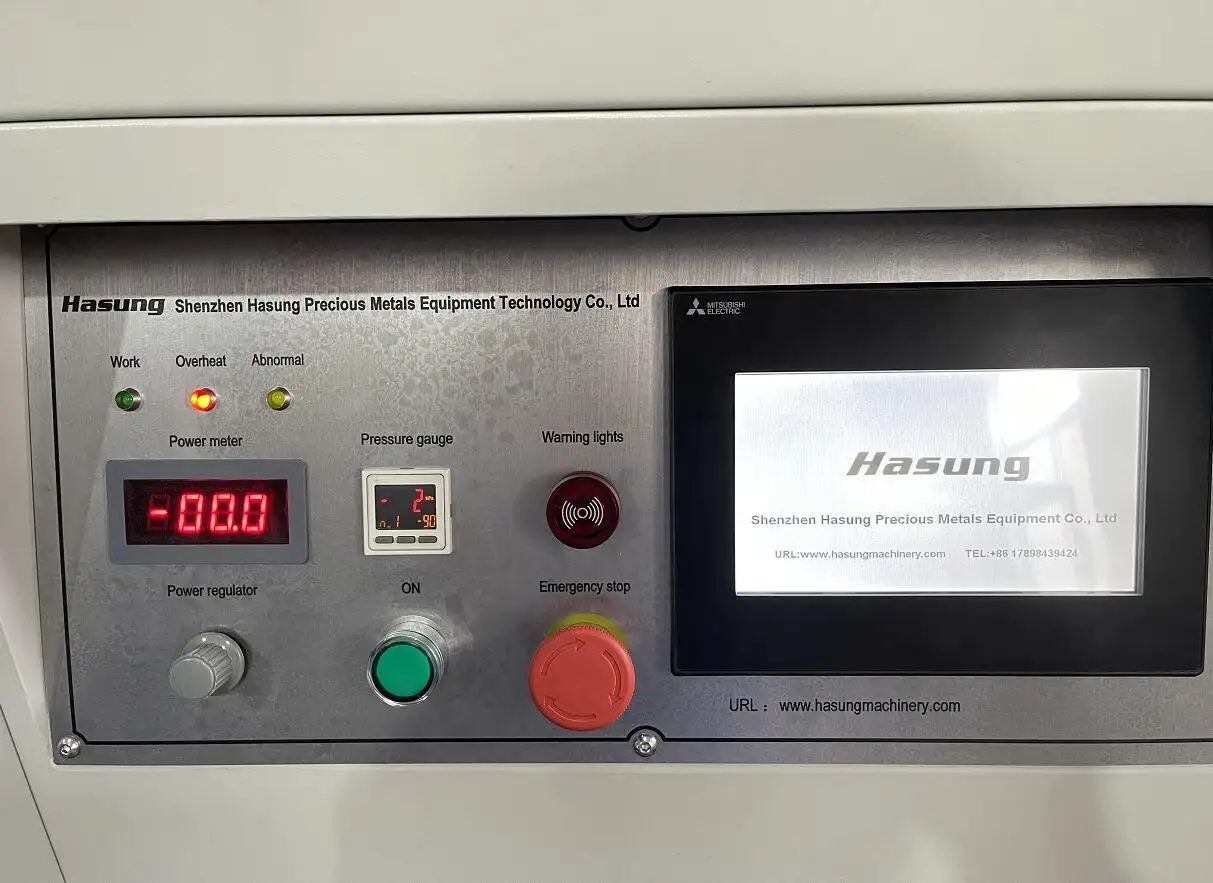

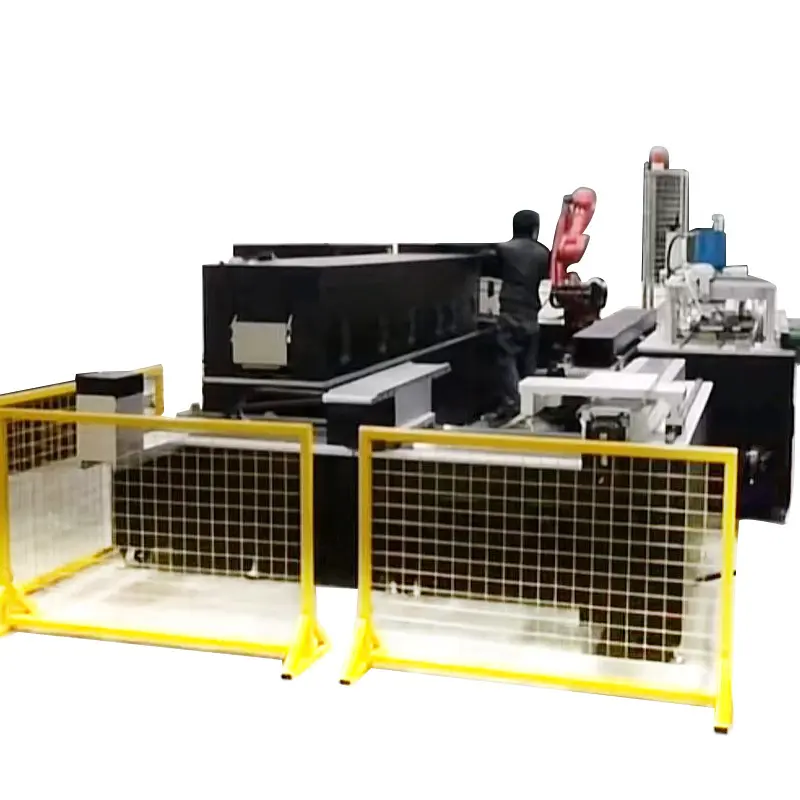

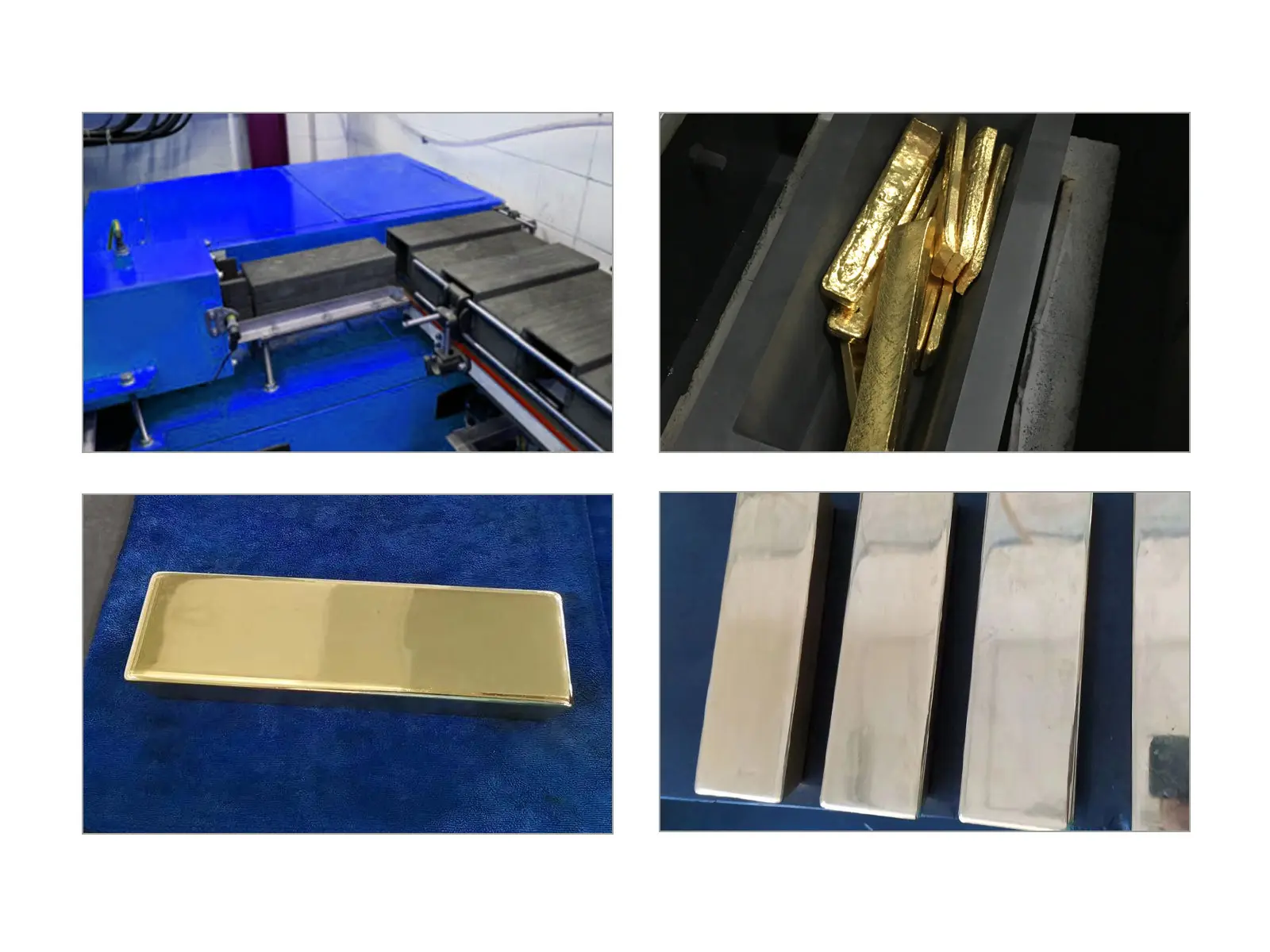

Hasung's fully automatic gold bullion vacuum casting machine system uses induction heating technology to efficiently melt and cast precious metals like gold. Its vacuum environment prevents oxidation, ensuring high - purity, high - quality bullion bars. The precious metal casting system's automatic operation, high - precision molds, and real - time monitoring enhance efficiency, reduce errors, and lower waste. Widely used in precious metals processing, it meets diverse customer needs for gold bullion bar production.

Considering the industry development and customers' requirements, Hasung has dedicated to the product development and we've made great achievements. After the Hasung full automatic gold bar making machine was launched, we received good feedback, and our customers believed that this type of product could meet their own needs.

| Place of Origin: | Guangdong, China | Condition: | New |

| Machine Type: | Precious Metals Casting Machinery | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2020 |

| Warranty of core components: | 2 years | Core Components: | PLC, Engine, Motor, Pressure vessel |

| Brand Name: | HASUNG | Voltage: | 380V, 3 phases |

| Power: | 60KW | Dimension(L*W*H): | 2500*1000*800(mm), customized |

| Warranty: | 2 years | Key Selling Points: | Easy to Operate |

| Showroom Location: | None | Applicable Industries: | Manufacturing Plant, Precious Metal Gold Silver Bar Casting Machines |

| Weight (KG): | 2200 | Application: | Gold, karat gold,silver and copper |

| Material: | main components are original from japan and germany | Type: | Induction Furnace |

| Dimensions: | 2500*1000*800(mm) | Technology: | IGBT |

| Duty cycle: | 100% | Max Temperature: | 1600C |

| Specification: | continuous casting gold bullions |

The First-Class Quality and Technology for Precious Metal Casting Equipment Manufacturer in China.

Tunnel Furnace Induction Gold Vacuum Casting Machine System

productivity: 4 blocks/hour, each block weighs 15kg;

Maximum working temperature: 1350-1400 degrees Celsius;

Type of protective gas: nitrogen; Air consumption: 5/H;

Furnace inlet water temperature and generator: up to 21 degrees Celsius;

Total water consumption: 12-13/H;

Required cooling water pressure: 3 to 3,5 bar;

Air flow required for ventilation: 0.1 m/s;

Required air pressure from the furnace: 6 bar;

Report Type and Separator: Graphite 400 oz;

The total area of the furnace installation is 18.2M2, the length is 26500mm, and the width is 2800mm.

The Induction Casting Machine Melting Tunnel Node Is Controlled By The Following Areas/Worksites:

Designed in stainless steel. Application: To pack gold particles into graphite sheets. Main

components: Electric push-step device displacement.

Input parameter area Use:

Restrict outdoor air from entering the tunnel Cooling system: water Main components: mobile partition with pneumatic control, nozzle Inject nitrogen.

Melting zone Usage:

used for smelting gold particles Cooling system: water Main components: inductor lined with refractory cement, infrared

Temperature sensor, nitrogen delivery system

Cooling zone.

partition with pneumatic control, nozzle Inject nitrogen. and vacuum.

Unloading zone.

Designed in stainless steel. Purpose:

Extract the finished product from the report.

Power Module, Overall Module: Power supply: 380v, 50Hz; 3 Phases Generator power:

60kW; others are 20KW. Total power required: 80KW

Control Zone:

Workspace for all furnaces

Why do You Choose Hasung Gold Bar Vaccum Induction Casting Machine?

Hasung precious metal vaccum casting machines compare to other companies

1. It’s a Big different. other companies vacuum are controlled by time.

They are not vacuum.They just pump it symbolically.When they stop pumping, it is not a vacuum. Ours pumps to the set vacuum level and can maintain the vacuum.

2. In other words, what they have are the vacuum setting time. For example, adding inert gas after one minute or 30 seconds is automatic.If it does not reach the vacuum, it will be converted to inert gas. It is In fact, the inert gas and the air are fed at the same time. It is not a vacuum at all. the vacuum cannot be maintained for 5 minutes. Hasung gold casting machine can maintain a vacuum for more than twenty hours.

3.We are not the same. We have drawn a vacuum. If you stop the vacuum pump,it can still maintain the vacuum. For a certain period of time,we will reach the set After setting the value, it can automatically switch to the next step and add inert gas

4.Hasung the original parts are from well-known domestic Japan and German brands.

Products Specifications:

Model No. | HS-VF260-1 | HS-VF260-15 | HS-VF260-30 | ||

Automatic Tunnel Furnace Gold Bar Vacuum Casting Machine | |||||

Power Supply | 380V ,50/60Hz 3 Phases | ||||

Power Input | 50KW | 60KW | 80KW | ||

Max Temp | 1600°C | ||||

Shielding Gas | Argon / Nitrogen | ||||

Temperature Accuracy | ±1°C | ||||

Capacity | 1kg 4pcs 1kg or 5pcs at a mould | 15kg/pcs | 30kg/1pcs | ||

Application | Gold, Silver, Copper | ||||

Vacuum | German Vacuum Pump, Vacuum degree-100KPA (optional) | ||||

Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||||

Control system | Mitsubishi PLC+Human-machine interface intelligent control system (included) | ||||

Cooling type | Water chiller(sold separately) or Running water | ||||

Dimensions | 2500X1200X1060mm | ||||

Weight | 2200KG | ||||

More related products:

FAQ

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and casting equipment, especially for high tech vacuum and high vacuum casting machines. Welcome to visit our factory in Shenzhen, China.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality? A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Q: Are your products good quality?

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115