Gas Atomization Furnace Equipment

Product features

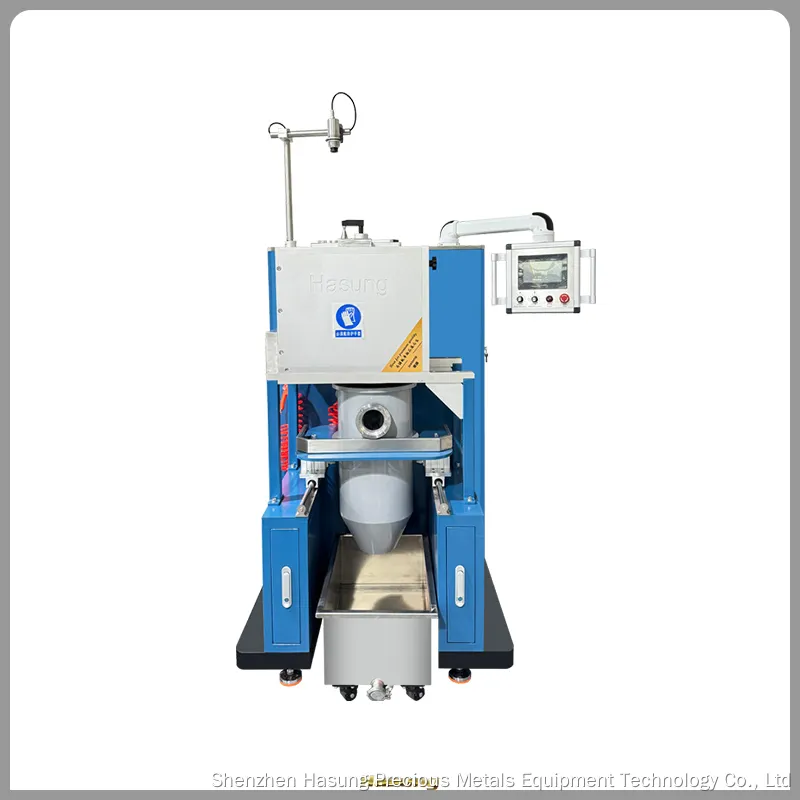

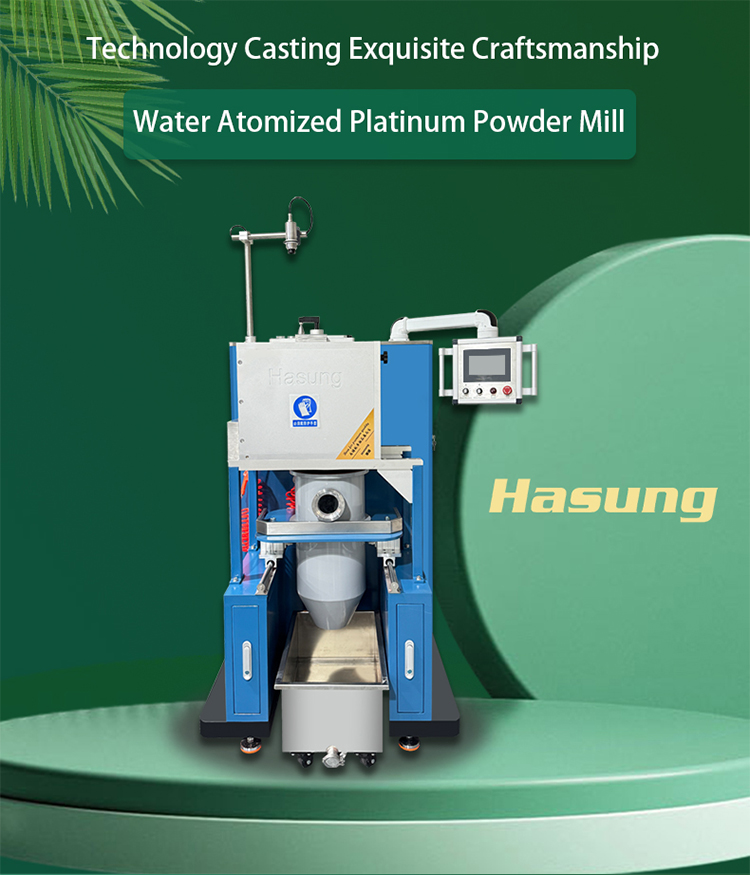

The gas atomization furnace equipment uses high-pressure liquid or gas flow to crush molten metal into small droplets, which solidify into metal powder with irregular or nearly spherical morphology and high purity. This equipment is essential for producing a variety of non-ferrous metal powders like platinum, palladium, stainless steel, and alloys. With advanced heating technology, precise temperature control, and adjustable particle sizes, this equipment ensures efficient and high-quality powder production for various industrial applications.

We serve

Gas Atomization Furnace Equipment is designed to produce fine metallic powders for a variety of industrial applications. Our equipment features state-of-the-art technology for precise control and consistent output. At our company, we serve with a commitment to quality and customer satisfaction. Our team of experienced professionals is dedicated to providing excellent service and support throughout the entire buying process. From initial inquiry to after-sales assistance, we are here to ensure your needs are met. Trust us to deliver high-performance equipment that meets your production requirements and enhances your overall efficiency. Experience the difference when you choose us as your partner in gas atomization furnace equipment.

Enterprise core strength

At Gas Atomization Furnace Equipment, we serve your needs with precision and efficiency. Our cutting-edge technology allows for the production of high-quality atomized powders for a wide range of applications. With our expertise in atomization processes, we are committed to delivering reliable and consistent results to our customers. From customized solutions to ongoing technical support, we strive to meet your specific requirements and exceed your expectations. Trust in Gas Atomization Furnace Equipment to provide the equipment and services you need to succeed in the competitive market. Partner with us and experience the difference of working with a dedicated team focused on serving you.

The specific process is that the alloy (metal) is melted and refined in an induction furnace, and the melted metal liquid is poured into an insulated crucible and enters a guide pipe. At this time, a high-pressure liquid flow (or gas flow) is sprayed from a spray plate, and the metal liquid is crushed into extremely small droplets by impact. The metal droplets solidify and fall in the atomization tower, and then fall into the powder collection tank for collection. The collected powder slurry is filtered and dehydrated, and finally dried, screened, weighed, and packaged into finished products.

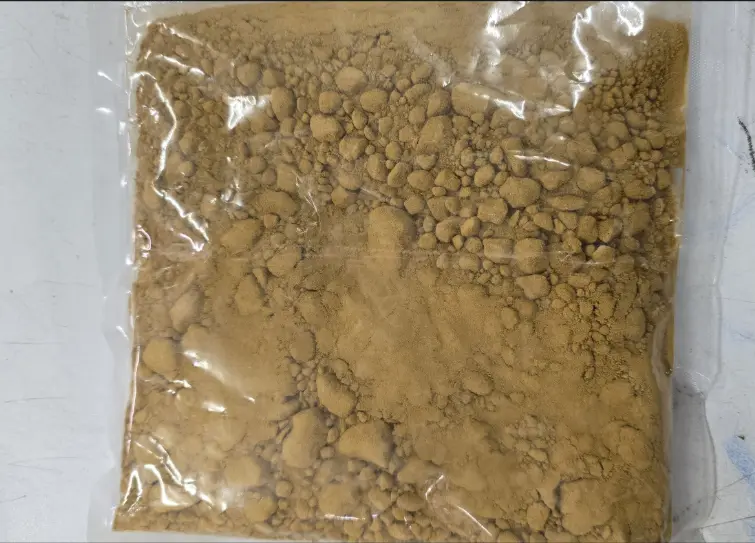

The metal powder produced by high-pressure water atomization has the following characteristics: irregular or nearly spherical morphology, high purity, low oxygen content, fast solidification speed, etc. It is widely used in the field of atomization of non-ferrous metal powders such as platinum powder, palladium powder, rhodium powder, iron powder, copper powder, stainless steel powder, alloy powder, etc.

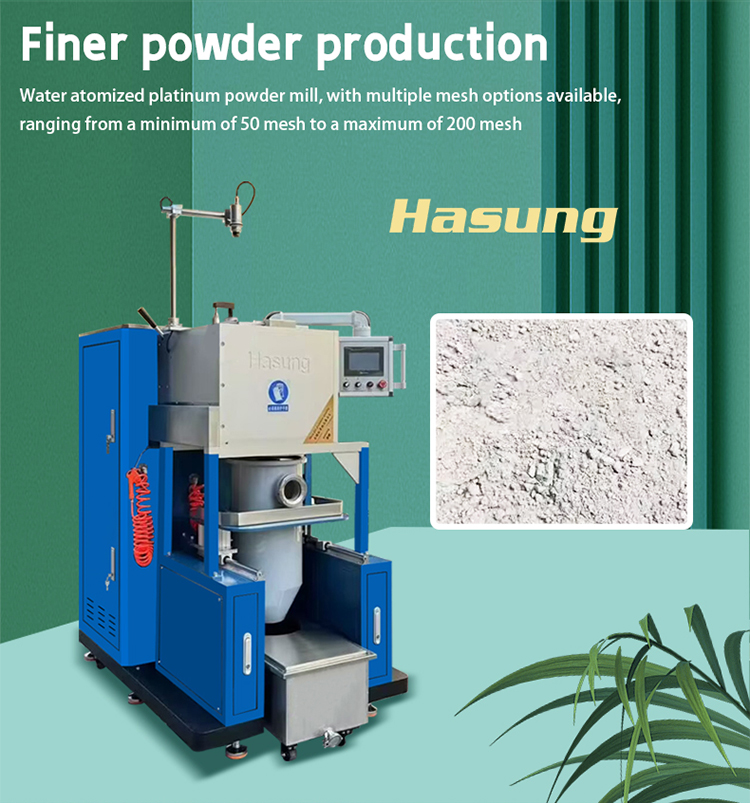

Water vapor atomization is actually a special water atomization process, which uses the strong negative pressure generated by high-pressure water jet to drive the gas in the atomization chamber to participate in atomization. Due to the intervention of a large amount of gas, the cooling rate of the powder is reduced, and the morphology of the powder is improved. Therefore, finer particles and more regular shapes of powder can be produced. Currently, it is mainly used for the production of stainless steel powder and amorphous powder.

Technical parameters:

| Model No. | HS-MIP2 | HS-MIP3 | HS-MIP4 | HS-MIP5 | HS-MIP10 |

| Voltage: | 380V,50Hz, 3 Phase | ||||

| Power | 15KW* 2 | 15KW* 2 | 15KW* 2 | 15KW* 2 | 30KW* 2 |

| Melting speed | 3-5 min. | 4-6 min. | 4-6 min. | ||

| Max. temp. | 2200C | ||||

| Temp. detector | Infrared pyrometer | ||||

| Application metals | platinum, palladium, rhodium, stainless steel, iron, gold, silver, copper, alloys, etc | ||||

| Heating technology | Germany IGBT induction heating | ||||

| Cooling method | Water chiller (sold separately) | ||||

| Cooling water consumpation | approx. 90 ltr./min. | ||||

| Cooling water pressure | 1-3bar | ||||

| Cooling water inlet temp. | 18-26 C | ||||

| Control system | 7" Weinview touch screen + Siemens PLC intelligent control | ||||

| Particle size | 80#, 100#, 150#, 200# (adjust.) | ||||

| Dimensions | 1020×1320 1680mm | 1220×1320 1880mm | |||

| Weight | Approximately 580kg | Approximately 650kg | Approximately 880kg | ||

High pressure water pump specifications:

| Voltage | 380V, 50Hz, 3 phase |

| Rated power | 22 KW |

| High-pressure water pressure | about 23 Mpa |

| Cooling water flow | approx. 50 ltr./min. |

| Dimensions | 1400*680*1340mm |

| Weight | approx. 620kg |

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115