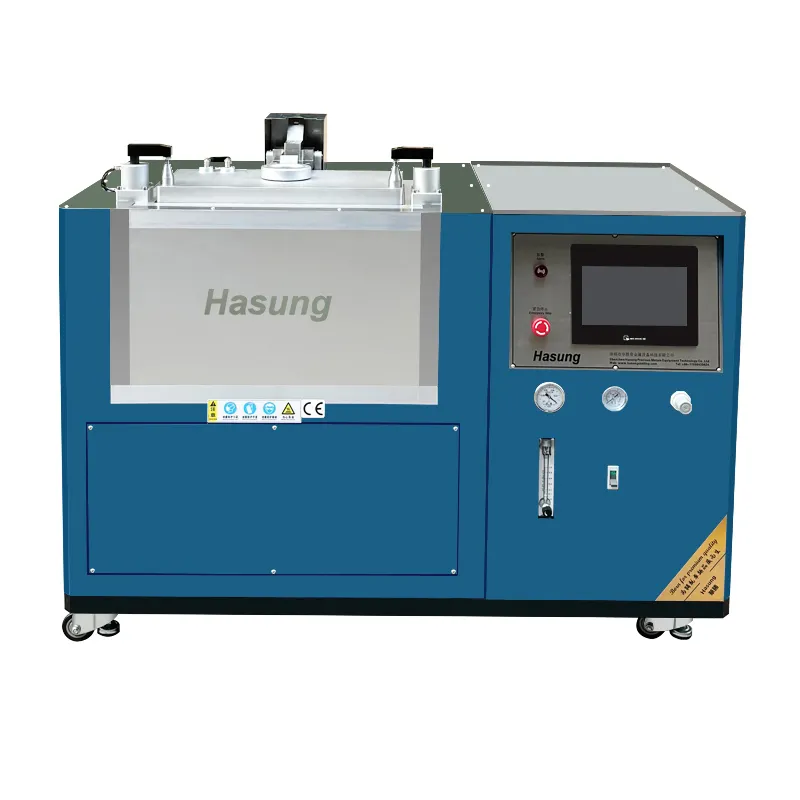

Gold Bar Vacuum Casting Equipment - Ultimate Solution for High Quality Bars

Product advantages

The Gold Bar Vacuum Casting Equipment is the ultimate solution for producing high-quality bars. Its advanced technology ensures precise and uniform casting, resulting in bars with superior purity and finish. With features such as temperature control, vacuum sealing, and automatic pouring, this equipment is essential for maximizing efficiency and quality in gold bar production.

Team strength

Team strength is a crucial aspect of the Gold Bar Vacuum Casting Equipment's success. Our dedicated team of engineers and technicians possess unmatched expertise in designing and manufacturing high-quality equipment. Their collective experience and innovation have led to the creation of a cutting-edge solution for producing gold bars with superior quality. Our team is committed to providing excellent customer service, ensuring that every client receives personalized attention and support throughout their experience with our product. With our team's expertise and dedication, you can trust that you are investing in a reliable and top-of-the-line equipment for your precious metal casting needs.

Enterprise core strength

At Gold Bar Vacuum Casting Equipment, our team strength lies in our unwavering commitment to excellence and expertise in the industry. With a dedicated group of skilled professionals who have years of experience in vacuum casting technology, we consistently deliver high-quality gold bars that exceed industry standards. Our team's collaborative approach and attention to detail ensure that every product that leaves our facility is of the utmost quality and precision. From our engineers to our technicians, each member plays a crucial role in ensuring the success of our ultimate solution for high-quality bars. Trust in our team's strength to provide you with exceptional results every time.

Shenzhen Hasung has always attached great importance to the pain points of the industry. The newly launched gold bullion vacuum casting equipment products are specially developed to solve the pain points of the industry, which perfectly solve the pain points of the industry and are enthusiastically sought after by the market. It has been proved that high-end technologies can contribute to the high-efficiency manufacturing process. In the field(s) of precious metal casting, factory supply metal vacuum casting machine for 1-15kg gold silver bullion casting is widely accepted by users. Hasung always adhere to the principle of 'creating values for customers and bringing benefits to stakeholders'. In the process of development, we highly focus on the quality and ensure no flawless product delivered to customers.

The First-Class Level Quality and Technology for Precious Metals Vacuum Casting Machine Manufacturer in China.

Technical Specifications:

| Model No. | HS-GV4 | HS-GV8 | HS-GV15 | HS-GV30 |

| Voltage | 380V ,50/60Hz 3 Phases | |||

| Power | 50KW / 65KW | 70KW / 80KW | ||

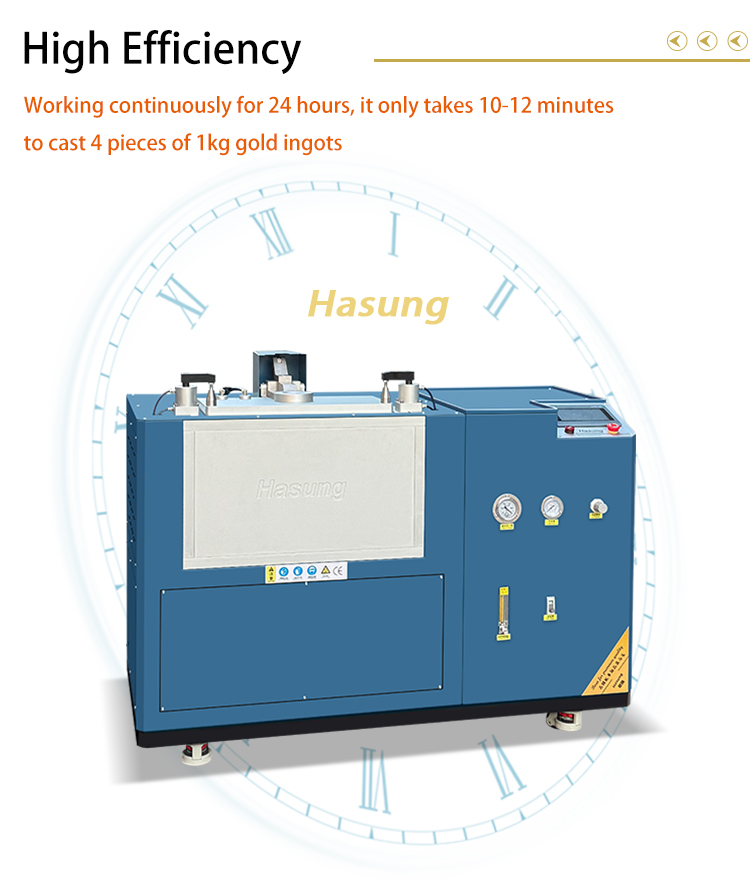

| Overall Casting Time | 10-15 mins. | 15-20 mins. | 12-15 mins. | 20-30 mins. |

| Capacity (Au) | 4kg : 4 pcs 1kg, 8pcs 0.5kg or more. | 8kg : 8pcs 1kg, or more | 15kg : 1pcs 15kg, or 5pcs 1kg or more | 1pcs 30kg or more. |

| Max Temperature | 1500°C | |||

| Inert gas | Argon / Nitrogen | |||

| Water Cooling Temperature | 20-25°C | |||

| Application metals | Gold silver | |||

| Vacuum pump | High performance value vacuum / German Vacuum Pump, Vacuum degree-100KPA (optional) | |||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |||

| Control system | 10" Taiwan Weinview/Siemens PLC+Human-machine interface intelligent control system or Siemens PLC touch panel | |||

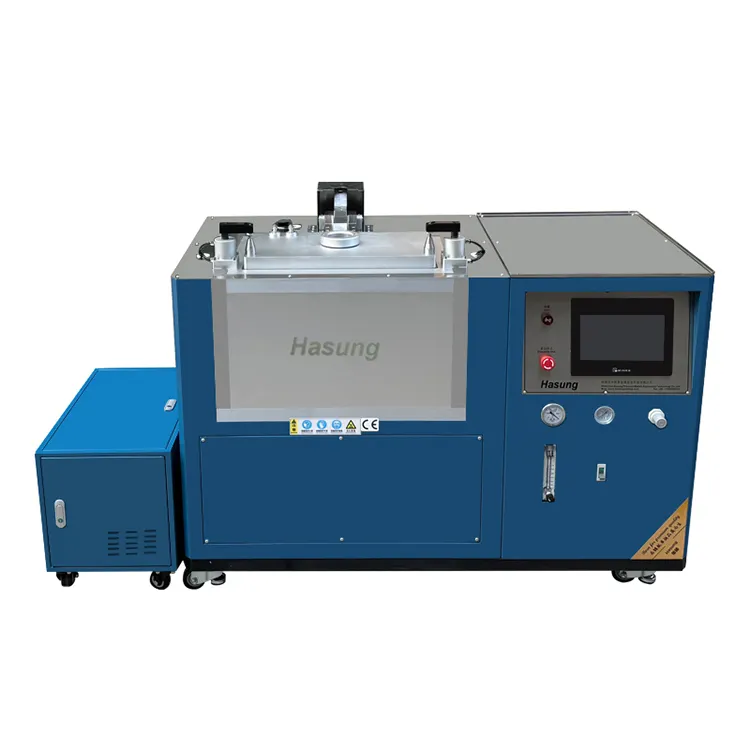

| Cooling type | Water chiller(sold separately) or Running water | |||

| Dimensions | 1460X720X1010mm / 1530X800X1060mm | |||

| Weight | 380kg / 450kg | |||

Descriptions:

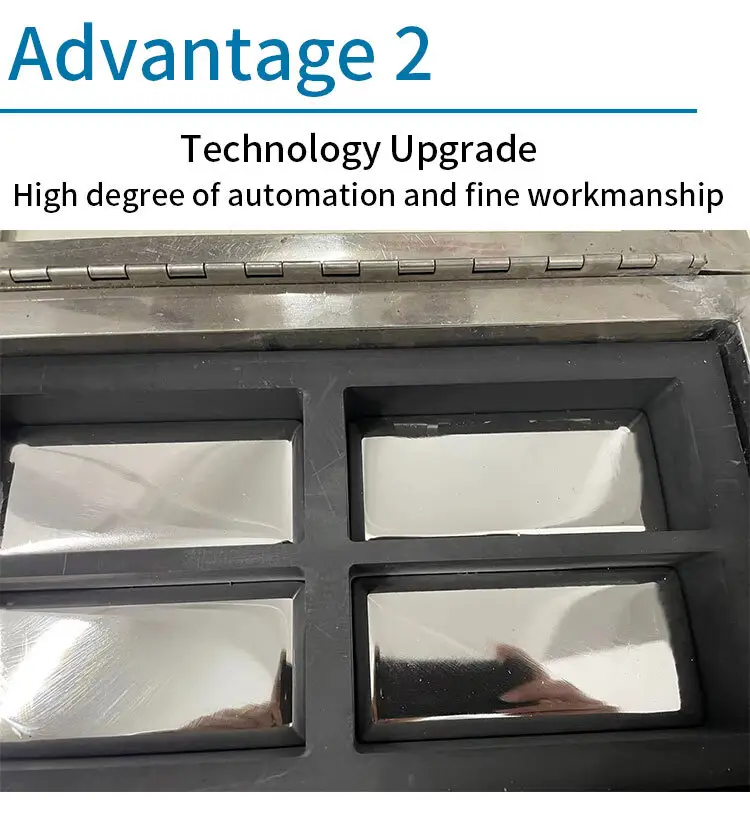

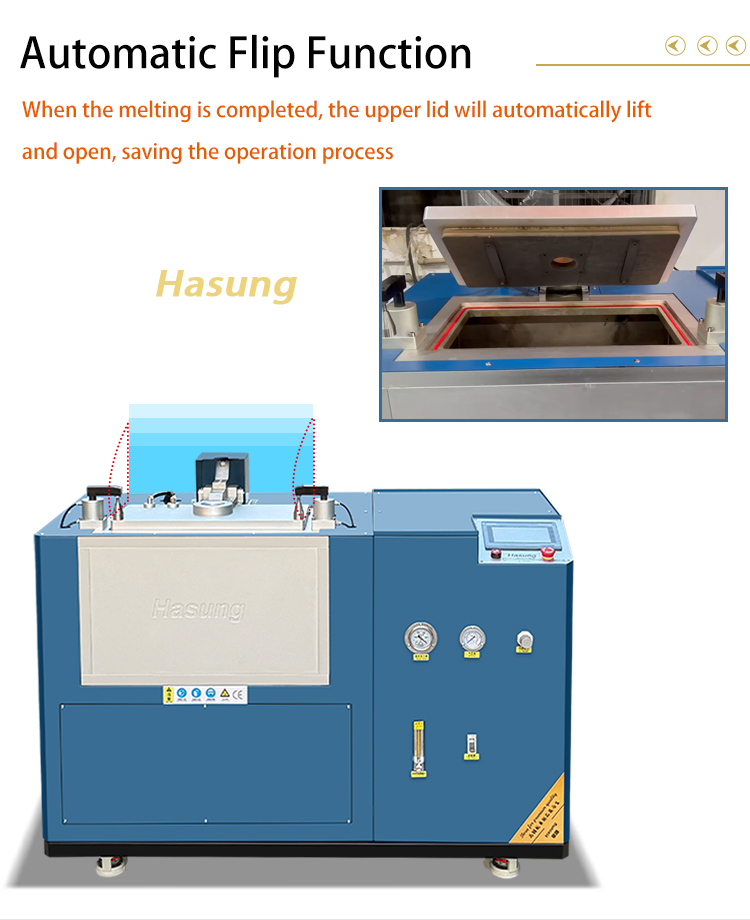

1. The most advanced full automatic precious metal casting system, One key can finish the entire casting process. Automatic close the cover–Automatic inert gas and vacuum-Automatic casting and cooling–Automatic open the cover–Take out the Shiny gold bar.

2. Control system: Taiwan 10" PLC+Human-machine interface intelligent control system (Siemens PLC touch screen is optional)

3. Using German IGBT induction heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving, and high work efficiency.

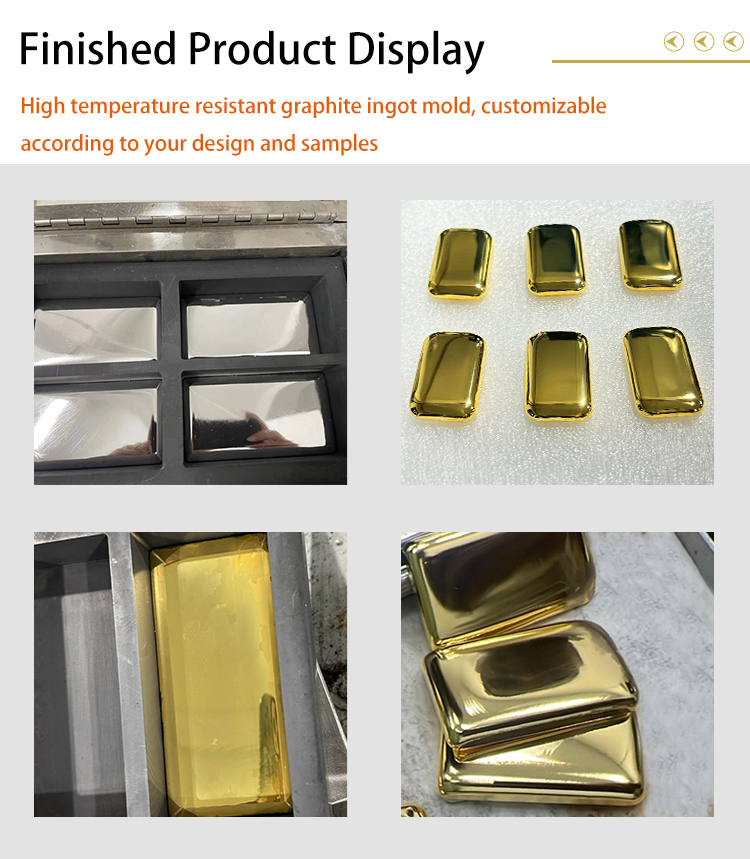

4. Melting under vacuum and inert gas protection atomophere which can prevent the oxidation of molten raw materials and without shrinkage, bubbles, etc. This equipment is suitable for the casting of high-purity gold silver materials.

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. This gold casting machine equipment uses Twaiwan PLC program control system or Siemens, Japan SMC/AirTec pneumatic components, Germany Omron, Schneider and Panasonic servo motor drive and other domestic and foreign brand components.

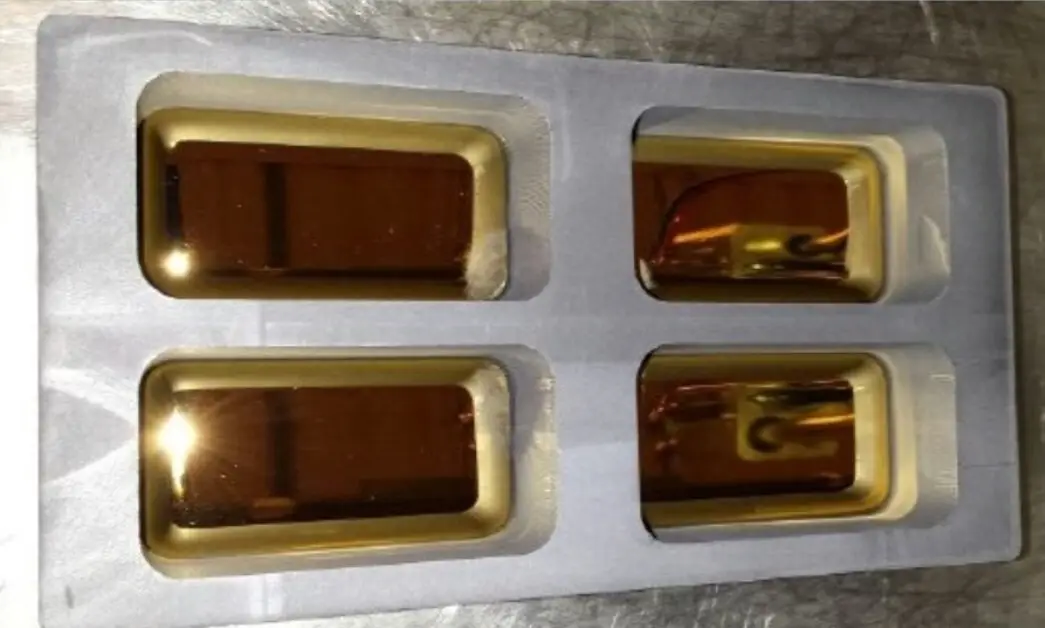

8. No oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

Why do You Choose Hasung Gold Bullion Vacuum Casting Equipment?

Hasung vacuum gold bar casting machine compare to other companies:

1.Advanced Technology: Utilizes induction heating for efficient melting of precious metals. This technology provides rapid heating capabilities, high energy efficiency, and precise temperature control. It can quickly raise the temperature of metals to their melting points, ensuring uniform heating and minimal thermal loss.

2.High-Quality Casting: Creates a vacuum environment during the precious metal casting process, preventing oxidation and contamination of the metals. This results in gold bullion bars with high purity and excellent surface quality.

3.Automation: Features fully automatic operation, reducing human intervention and minimizing the risk of errors. Equipped with advanced sensors and control systems that monitor and adjust various parameters in real-time.

4.Precision: Employs high-precision casting molds for accurate shaping of gold bullion bars. The molds ensure tight dimensional tolerances and smooth surfaces.

5.Efficiency: Enhances production efficiency and reduces material waste.

6.Versatility: Capable of handling various types and specifications of gold materials, meeting diverse customer needs.

Features:

✔ 24 hours of continuous working will meet your long-time casting goal.

✔ Easy control with HMI interface. The most advanced model, fully automatic control.

✔ The gold vacuum casting machine avoids bullion’s oxidation, shrinkage, and water wave under the vacuum cabinet.

✔ The casting condition is fully sealed to avoid flame for the safety of workers.

✔ The smooth and shiny surface which can improve your bullion quality

✔ The metal vacuum casting machine saves 3 times argon than all the other competitors.

✔ The vacuum tightness is more than 18 hours when stop vacuuming, yet it means vacuum is the best.

Introducing the Hasung Gold Bar Vacuum Casting Machine

The ultimate solution for producing flawless, high quality gold bars. This state-of-the-art machine is designed to produce mirror-like noodles without shrinkage or pores, ensuring a perfect finish every time. Whether you are a gold refiner or gold dealer, this must-have equipment will revolutionize your production processes and improve product quality.

In addition to excellent output quality, this machine is designed with efficiency and ease of use in mind. Its user-friendly interface and intuitive controls make operation simple, allowing operators to focus on the production process without unnecessary complications. This streamlines workflow and maximizes productivity, ultimately saving costs and improving overall efficiency.

In addition, the gold bar vacuum casting machine is able to withstand the harsh conditions of continuous use in harsh production environments. Its rugged construction and durable components ensure long-term reliability, minimizing downtime and maintenance requirements. This reliability is critical for businesses that rely on stable output to meet market demand and maintain a competitive advantage.

For gold refiners, this gold bullion vacuum casting equipment has significant advantages in producing high-purity gold bars. Precise control of the casting process ensures that impurities are minimized, resulting in rods that meet the most stringent purity standards. This is vital to maintaining the integrity of the refining process and delivering gold bars that command a premium in the market.

Likewise, gold dealers can leverage this machine to differentiate their products and build a reputation for excellence. The ability to consistently produce perfect gold bars sets them apart from their competitors and instills confidence in their customers. Whether used for investment purposes or for jewelry making, the superior quality of machine-produced gold bars is a compelling selling point.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115