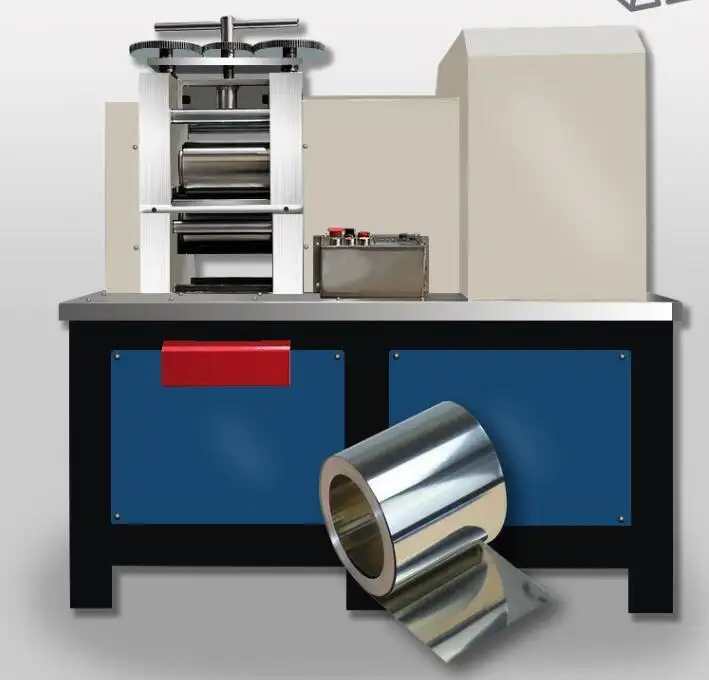

Hasung 20HP Electric Rolling Mill - Silver Wire Making Machine

Product features

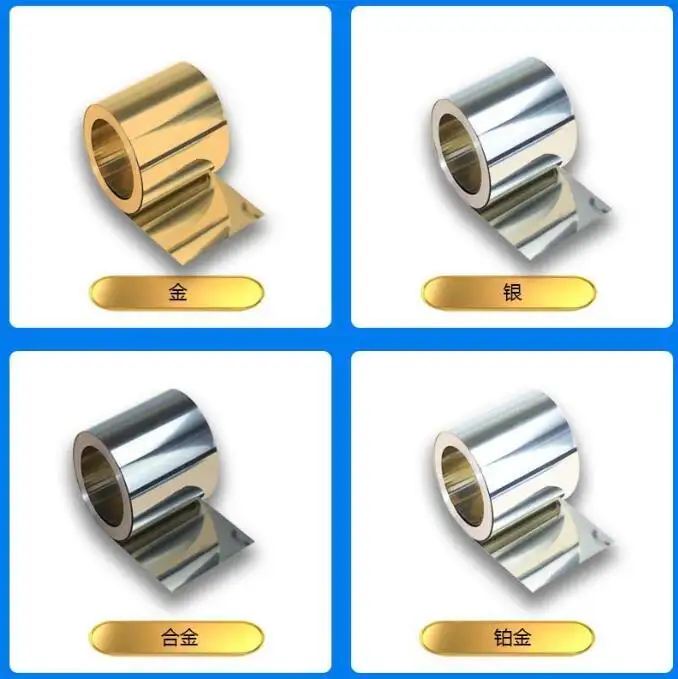

The Hasung 20HP Electric Rolling Mill in Silver is a powerful and versatile silver wire making machine designed to meet the demanding needs of metalworking professionals. With its durable construction, advanced features, and precise controls, this rolling mill allows for efficient shaping and forming of metals like gold, silver, and copper. Its adjustable rollers and customizable settings provide flexibility for different metalworking tasks, making it an essential addition to any shop or manufacturing facility specializing in silver wire production.

Company profile

Hasung is a leading manufacturer of high-quality and reliable wire making machines, with a strong focus on innovation and customer satisfaction. Our 20HP Electric Rolling Mill in Silver is designed for efficiency and precision, offering top-of-the-line performance for all your wire production needs. With over a decade of experience in the industry, we pride ourselves on delivering products that meet the highest standards of quality and durability. Our commitment to excellence drives us to constantly improve and innovate, ensuring that our customers always have access to the latest technology and advancements in wire making equipment. Trust Hasung for all your wire making needs.

Enterprise core strength

With over 10 years of experience in the manufacturing industry, Hasung is a leading provider of high-quality wire making machines. Our 20HP Electric Rolling Mill is designed to produce silver wires with precision and accuracy. Each machine is crafted with superior craftsmanship and cutting-edge technology to ensure optimal performance. At Hasung, we are committed to providing our customers with innovative solutions that meet their specific needs. Our dedication to quality and customer satisfaction sets us apart from the competition. Trust Hasung for all your wire making needs and experience the difference in quality and performance.

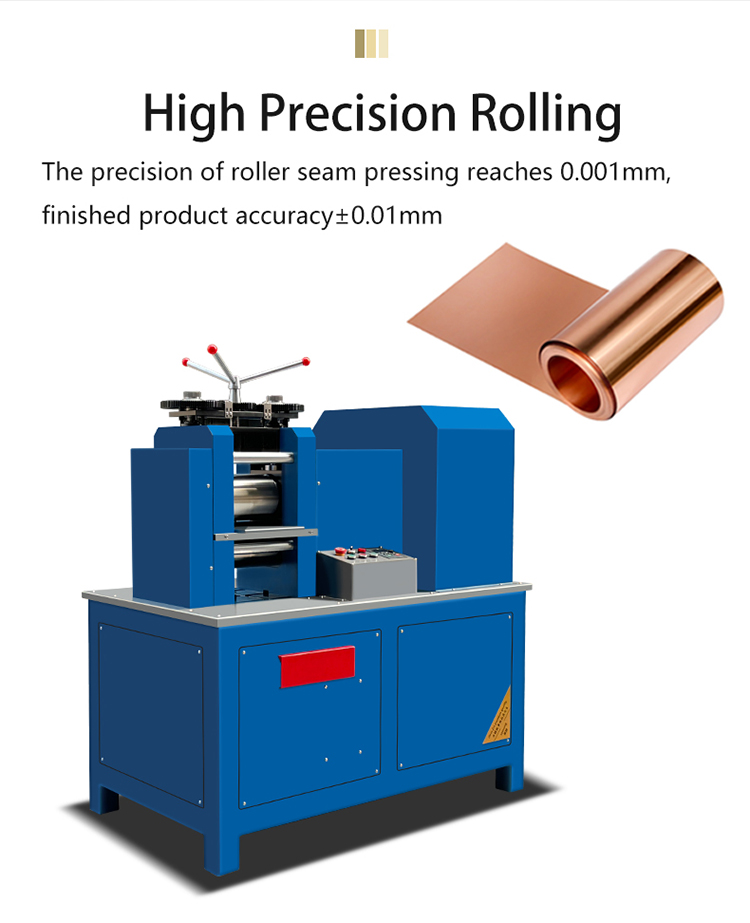

The 20HP jewelry rolling machine by Hasung is a powerful tool for jewelry making. It features a robust 20HP motor, ensuring efficient and precise rolling of metal sheets and wires. The jewelry rolling mill machine offers adjustable rollers for various thicknesses, making it versatile for different jewelry components. Its sturdy construction and advanced technology ensure durability and accuracy, ideal for both small-scale artisans and large workshops.

Company Advantages

More than 30 patents for machines.

It is extensively used in precious metals refining, precious metals smelting, precious metals bars, beads, powders trading, gold jewellery, etc.

With first class level quality self-manufactured machines, enjoy high reputation.

We provide freely design for your graphite moulds before ordering our machines

Name | 20HP Electric Jewelry Rolling Machine |

Model No. | HS-20HP |

Brand Name | HASUNG |

Voltage | 380V; 50/60hz 3 phases |

Power | 15KW |

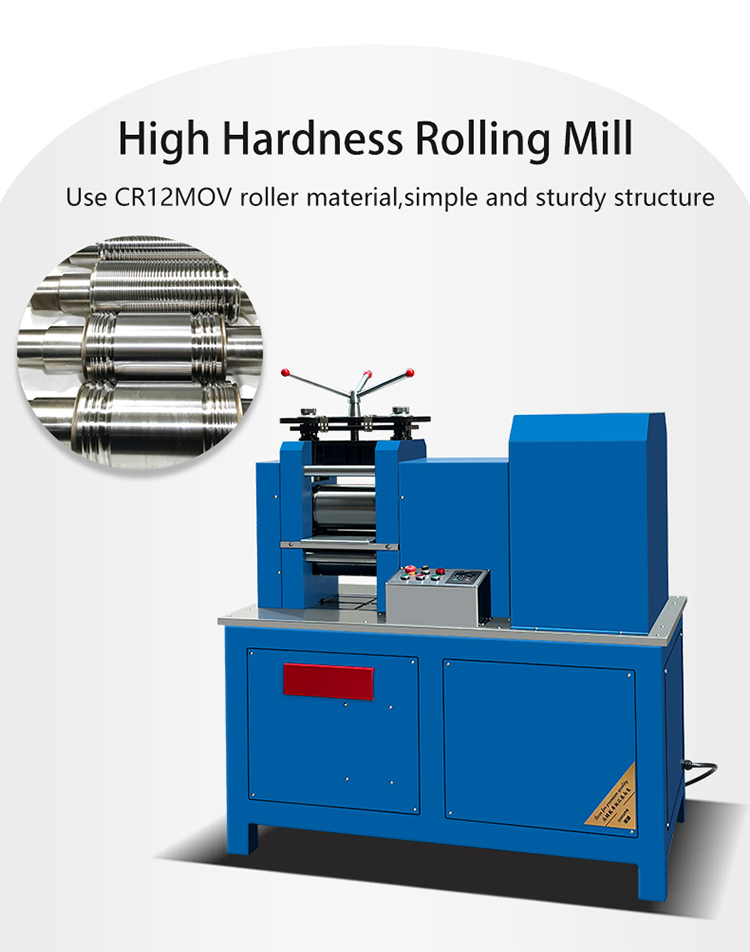

Hardness | 60-61 ° |

Roller material | D2 or DC53 |

Roller size | Diameter 200 x width 300mm |

| Max input sheet | 35mm |

| Min. output sheet | 0.10mm |

| Dimensions | 160x140x160cm |

Weight | approx. 2500kg |

Features At A Glance:

1.The 20HP jewelry rolling press machine equipment features a powerful 20HP motor that ensures efficient and precise rolling of metal sheets and wires. The machine operates on a 380V, 50Hz, 3-phase power supply, providing stable and reliable performance.

2.The jewelry rolling mill machine is equipped with rollers made from high-quality materials such as Cr12MoV, which offers excellent hardness and durability. The roller diameter is typically around 96mm, and the sheet rolling mill can handle a maximum sheet thickness of 35mm. The minimum output sheet thickness can be as thin as 0.10mm, making it suitable for creating delicate jewelry pieces.

3.The Hasung 20HP jewelry rolling machine is designed for continuous operation, with a duty cycle of 100% and a maximum rolling speed of 75m/min. This high-speed rolling capability ensures high productivity. The machine dimensions are approximately 1800x900x1800mm, and it weighs around 2500kg, providing a sturdy and stable working platform.

Advantages:

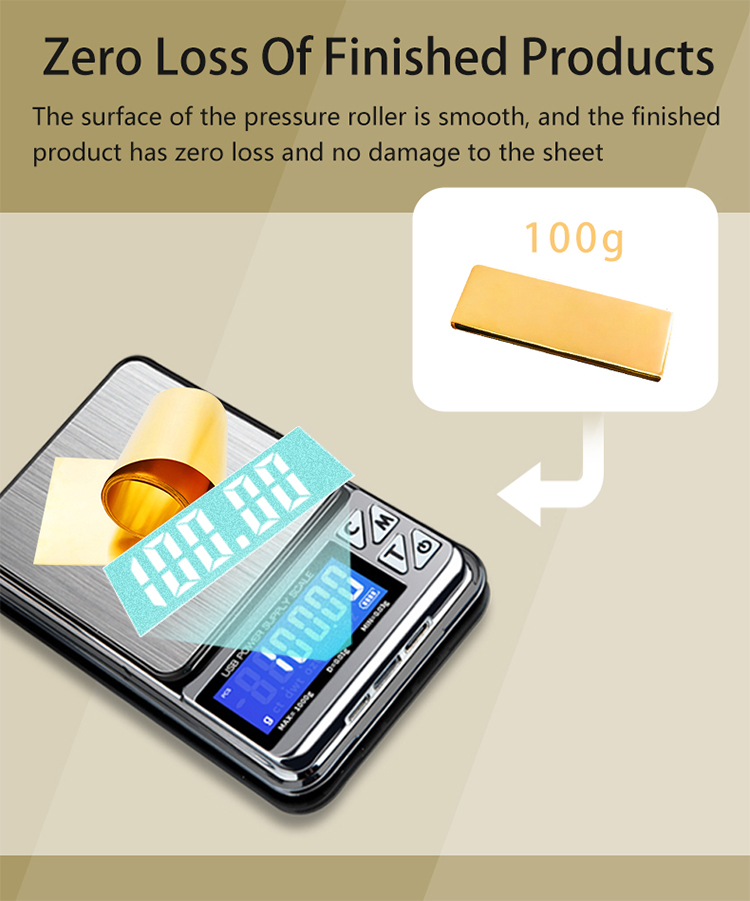

1.This state-of-the-art machine is engineered to provide precision and efficiency in shaping and forming all types of metals, including gold, silver and copper. With its heavy-duty construction and advanced features, this jewelry rolling mill is a must-have addition to any shop or manufacturing facility.

2.Rolling mill for jewelry is manufactured from the highest quality materials and are built to withstand the rigors of continuous use in industrial environments. Its sturdy frame and durable components ensure long-lasting performance, making it a solid investment for businesses looking to enhance their metalworking capabilities. Whether you are a jewelry maker, metal artist, or industrial fabricator, this machine delivers the precision and power you need to achieve superior results in metal shaping and shaping.

3.The machine for gold, silver, and copper are equipped with an advanced rolling mechanism that allows users to easily manipulate sheet metal and wire with unparalleled precision. Its smooth and efficient operation allows for precise control of metal thickness and shape, making it ideal for creating custom jewelry pieces, intricate designs, and industrial components.

4.The 20 HP jewelry rolling machine can handle a variety of metalworking tasks with ease. Whether you're flattening, shaping or texturing metal, this machine offers the flexibility and adaptability you need to tackle different projects. Its adjustable rollers and customizable settings give users the freedom to try different techniques and achieve unique results.

5.sheet rolling mill for gold, silver, and copper are designed with user convenience in mind. Its intuitive controls and ergonomic design make it easy to operate, ensuring a seamless metalworking experience for experienced professionals and beginners alike.

Whether you're crafting intricate jewelry, fabricating industrial components, or exploring new possibilities in metalworking, this heavy duty rolling mill delivers the precision, power, and versatility needed to bring your creative vision to life.

FAQs

How do you choose the right jewelery rolling mill for your precious metals?

The first thing to consider when choosing a rolling mill is the type of metal you will be working with. Different metals have different properties and not all rolling mills are suitable for all types of metals. For example, if you primarily handle gold and silver, you will need a machine specifically designed to handle these softer metals. On the other hand, if you are working with a harder metal like platinum, you will need a rolling mill that can apply higher pressure to effectively shape the metal. Another important factor to consider is the width and thickness of the metal you will be using. Rolling mills come in a variety of sizes and capacities, so it's crucial to choose a machine that's right for your metal size. If you work with a variety of metal thicknesses, consider a rolling mill with adjustable rollers to provide versatility in your job.

The quality and durability of the rolling mill are also crucial considerations. Investing in a high-quality machine may come with a higher price tag, but it will save you money and frustration in the long run. Look for machines made of sturdy materials, such as hardened steel, as they are better able to withstand the stress and wear and tear of daily use. Additionally, consider the manufacturer's reputation and read reviews from other users to gauge the machine's reliability and performance. Ease of use and maintenance are also important factors to consider when selecting a rolling mill. Look for a machine that is user-friendly and comes with clear operating and maintenance instructions. Some machines may require periodic lubrication or adjustments, so ongoing maintenance requirements must be considered when making your decision.

The features and accessories that come with the mill will also influence your choice. Some machines come with additional rollers or attachments that expand the machine's capabilities, allowing you to create a wider variety of shapes and textures in your metalwork. Consider your specific needs and the type of work you will be doing to determine which features are critical to your project. In addition to the machine itself, consider the level of customer support and the manufacturer's available resources. A reputable company will offer customer support, warranty options, and resources like instructional videos or seminars to help you get the most out of your rolling mill.

Finally, consider your budget when choosing a rolling mill. While it's important to invest in high-quality machinery, it's also important to find a balance between cost and quality. Consider the long-term value of the machine and how it will improve the quality and efficiency of your work.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115