Hasung Jewelry Casting Equipment - Vacuum Granulating Machine, Superior Performance & Customizable Specs

Product features

The Hasung Jewelry Casting Equipment - Vacuum Granulating Machine offers superior performance with customizable specs for electric induction melting furnaces. This machine features a closed type + vacuum/inert gas protection melting chamber to prevent oxidation and impurities, making it ideal for high-purity metal casting. With its Mistake Proofing automatic control system and PID temperature control, this equipment ensures accurate temperature control and efficient production processes for gold, silver, copper, and alloys.

We serve

At Hasung Jewelry Casting Equipment, we serve as dedicated experts in providing top-of-the-line Vacuum Granulating Machines that are unmatched in performance and customizable specs. Our commitment to excellence shines through in every aspect of our products, ensuring superior quality and precision for all your jewelry casting needs. With a focus on innovation and customer satisfaction, we strive to exceed expectations and deliver reliable equipment that meets the highest industry standards. Trust in Hasung to provide the tools you need to elevate your craft and create stunning jewelry pieces with ease. Choose Hasung for unparalleled service and exceptional results.

Why choose us

At Hasung, we serve jewelry makers with our top-of-the-line casting equipment, specifically our Vacuum Granulating Machine. With superior performance and customizable specs, our machine ensures the highest quality results for your jewelry casting needs. We are dedicated to providing innovative solutions that meet the unique requirements of our customers, allowing them to create flawless pieces with ease. Our commitment to excellence and customer satisfaction sets us apart in the industry, making us the go-to choice for jewelry casting equipment. Trust Hasung to serve your needs and elevate your craft to new heights.

Shenzhen Hasung Precious Metals Equipment Co., Ltd still remembered the time when we successfully developed the new product - Jewelry casting machinery Precious metal Gold silver Copper Vacuum Granulating machine. The product is absolutely new and has something different in it. It is delicately designed to comply with the industry standard. With regard to its design, Jewelry casting machinery Precious metal Gold silver Copper Vacuum Granulating machine is designed by a team of our designers who are always close to the industry trend and keep alert to the changes.

| Place of Origin: | Guangdong, China | Condition: | New, 100% Brand New |

| Machine Type: | casting | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2020 |

| Warranty of core components: | 2 years | Core Components: | PLC, Engine, Motor |

| Brand Name: | Hasung | Voltage: | 220V/380V |

| Power: | 8KW 15KW, 8KW | Warranty: | 2 years, 2 years |

| Key Selling Points: | Accurate temperature control | Showroom Location: | None |

| Applicable Industries: | Manufacturing Plant, Energy & Mining, Other | Weight (KG): | 120 |

| Feature: | Superior quality | Power Supply: | 380V |

| Capacity: | 2kg | Application: | Gold, silver, copper, alloys |

| Dimensions: | 880x680x1530mm | Weight: | 120kg |

| Certification: | ISO CE |

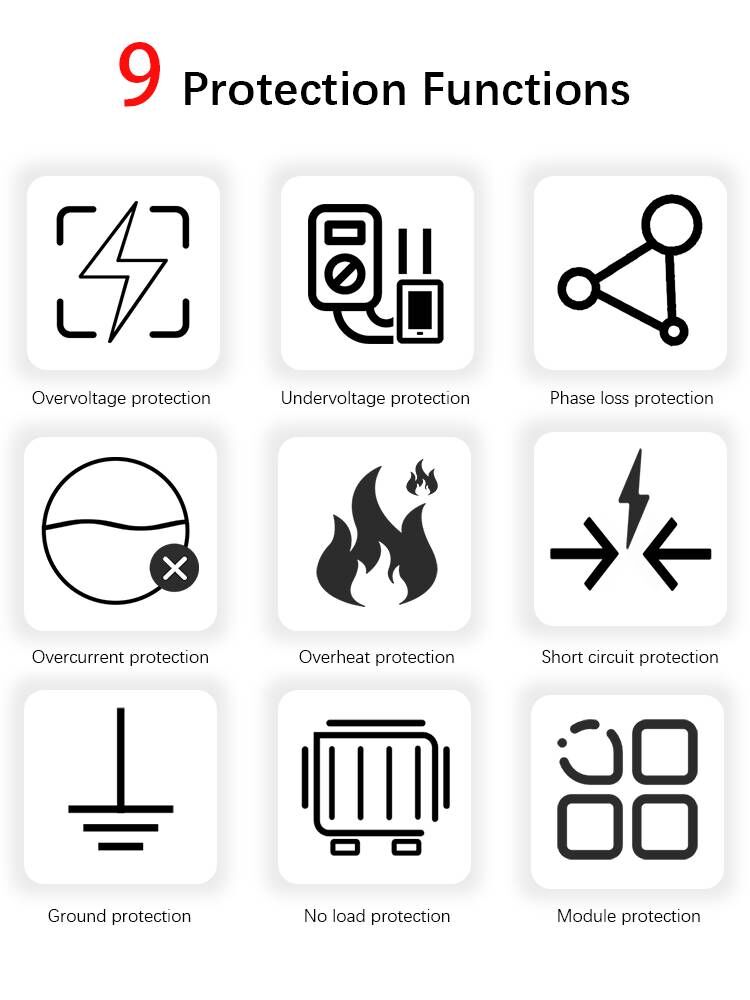

Using high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency. 2. The closed type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals. 3. Using a closed + vacuum/inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved. 4. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible. 5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color. 6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use. 7. Using PID temperature control system, the temperature is more accurate (±1°C). The HS-GR vacuum system casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of gold, silver, copper. 9. This equipment uses imported PID program control system, SMC pneumatic and Panasonic servo motor drive and other well-known brand components at home and abroad. 10. Melting, electromagnetic stirring, and refrigeration in a closed + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

- Hasung Precious Metals Equipment advantages

1. The product has uniform color and no segregation:

The porosity is reduced, and the density is higher and constant, reducing post-processing work and reducing loss.

2. Better material fluidity and mold filling, lower enthusiasm risk:

Vibration improves material flow, and the material structure is more compact. Improve shape filling and reduce the risk of hot cracks

3. The grain size is reduced to 50%:

Solidify with a finer and more uniform structure

4. Better and more stable material properties:

The tensile strength and elasticity are increased by 25%, and the subsequent processing performance is improved.

Why do You Choose Hasung Vaccum Pressured Casting Machine ?

Hasung Vacuum Casting machines compare to other companies

1. It’s a Big different. other companies vacuum are controlled by time.They are not vacuum.They just pump it symbolically.When they stop pumping, it is not a vacuum.Ours pumps to the set vacuum level and can maintain the vacuum.

2. In other words, what they have are the vacuum setting time.For example, adding inert gas after one minute or 30 seconds is automatic.If it does not reach the vacuum, it will be converted to inert gas. It is In fact, the inert gas and the air are fed at the same time. It is not a vacuum at all. the vacuum cannot be maintained for 5 minutes.Hasung can maintain a vacuum for more than twenty hours.

3.We are not the same. We have drawn a vacuum. If you stop the vacuum pump,it can still maintain the vacuum. For a certain period of time,we will reach the set After setting the value,it can automatically switch to the next step and add inert gas

4.Hasung's original parts are from well-known domestic Japan and German brands.

Technical data

| Model No. | HS-GR1 | HS-GR2 | HS-GR3 | HS-GR4 | HS-GR5 | HS-GR6 | HS-GR8 | HS-GR10 | HS-GR30 | HS-GR50 |

| Voltage | 220V, 50/60Hz single phase | 380V, 50/60Hz 3 phases | ||||||||

| Induction Generator Power | 8KW | 15KW | 20KW | 30KW/40KW | ||||||

| Capacity (Au) | 1kg | 2kg | 3kg | 4kg | 5kg | 6kg | 8kg | 10kg | 30kg | 50kg |

| Melting speed | 2-3 min. | 3-6 min. | 2-3 min. | 3-6 min. | 5-8 min. | 2-3 min. | 3-6 min. | 5-8 min. | 5-8 min. | 10-20 min. |

| Max Temperture | 1500℃ | |||||||||

| Temp Accuracy | ±1°C | |||||||||

| Application | Gold, K gold, silver, copper and other alloys | |||||||||

| Inert Gas | Argon / Nitrogen | |||||||||

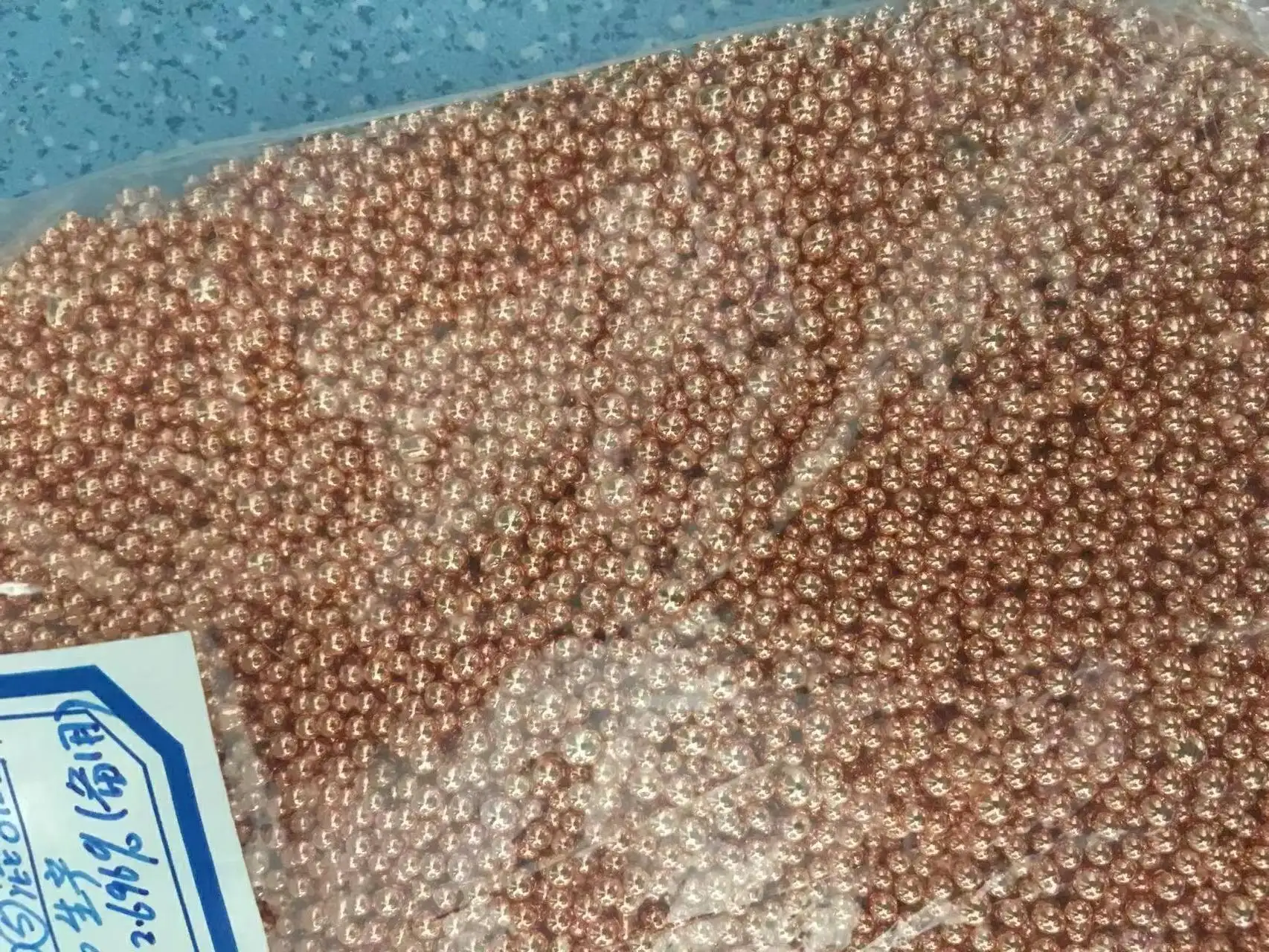

| Grain size | 1.8-4.0mm | |||||||||

| Cooling type | Running water / water chiller (sold separately) | |||||||||

| Control system | Mitsubishi PLC+Human-machine interface intelligent control system (optional) | |||||||||

| Vacuum | High vacuum degree vacuum pump / German Vacuum Pump, Vacuum degree-100KPA | |||||||||

| Components | Using world famous brands such as Siemens, AirTec, SMC, Schneider, Omron, etc. | |||||||||

| Dimensions | 880x680x1560mm | |||||||||

| Weight | approx. 120kg | approx. 150kg | approx. 180kg | approx. 280kg | ||||||

Gold Silver Granulating Process:

Shenzhen Hasung Precious Metals Equipment Co.,Ltd,

Our R & D department is always working on developing casting and melting technologies to suit our ever changing industry for theNew Materials industry, Aerospace, Gold Mining, Metal Minting Industry, Research laboratories, Rapid Prototyping, Jewellery, and Artistic Sculpture. We do provide precious metals solutions for customers. We uphold the principle of "integrity, quality,cooperation, win-win" business philosophy,committed to creating first-class products and services.We always believe that technology changes the future.

We specialize in designing and developing custom finishing solutions. We strive to make the finishing process faster and more economical. Welcome to visit us

Customers

About Hasung

Company Advantages

More than 30 patents for machines.

We provide a one-stop service for precious metals casting solutions.

It is extensively used in precious metals refining, precious metals smelting, precious metals bars, beads, powders trading, gold jewellery, etc.

We provide freely design for your graphite moulds before ordering our machines.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115