Hasung VCT Series Investment Casting Machine

Product features

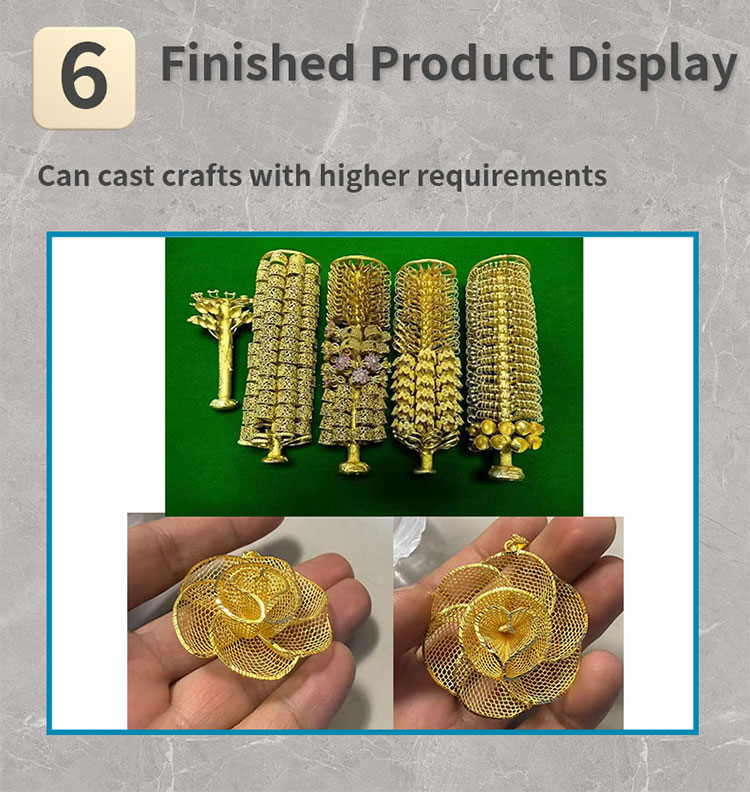

The Hasung VCT Series Investment Casting Machine is a cutting-edge pressure vacuum casting machine specifically designed for jewelry production. It features a 7-inch color touch screen, medium-frequency generators, and computer-managed power control for efficient operation. With automatic processes including vacuum, heating, strong magnetic mixing, casting, and more, this machine ensures precise and high-quality results for gold, silver, and alloy casting.

Team strength

At Hasung, our VCT Series Investment Casting Machine represents the pinnacle of teamwork and collaboration. Our team is comprised of industry experts who bring together their unique skills and knowledge to create cutting-edge technology that revolutionizes the investment casting process. With a focus on innovation and precision, our team works seamlessly to ensure that each machine meets the highest standards of quality and performance. By harnessing the collective strength of our team, we are able to deliver a product that not only meets, but exceeds, the expectations of our customers. Experience the power of teamwork with Hasung VCT Series Investment Casting Machine.

Enterprise core strength

At Hasung, our VCT Series Investment Casting Machine is the result of our team's unwavering commitment to excellence. Our dedicated engineers and technicians work seamlessly together to design and manufacture cutting-edge casting machines that deliver superior precision and efficiency. With a collective expertise in the industry, our team continuously collaborates to innovate and improve our products, ensuring they meet the highest standards of quality and performance. When you choose Hasung, you can trust that you are investing in a product that embodies the strength and expertise of a team driven by passion and dedication to perfecting their craft.

Having invested a great deal of funds to technology research and product development,Shenzhen Hasung Precious Metals Equipment Co., Ltd has successfully worked out Premium Quality Hasung metal casting machinery for gold metal casting machine. The product is characterized by multiple advantages.Its application ranges have been expanded to the Jewelry Tools & Equipment. Influenced by the market trends and customers' requirements, the design of Precious Metals Melting Equipment, Precious metals casting machine, gold bar vacuum casting machine,gold silver granulating machine,precious metals continuous casting machine,gold silver wire drawing machine, vacuum induction melting furnace,precious is made to be unique. It adopts the raw materials that have been tested to conform to the quality standards, which guarantees its quality from the source.

PRODUCT DESCRIPTION

Hasung VCT series casting machine is the most innovative in the latest generation of pressure vacuum casting machine in the world market. They use medium-frequency generators, and the power control is proportional and is managed entirely by a computer. The operator simply puts the metal into the crucible, places the cylinder and presses the button! The "VCT" series model comes with a 7-inch color touch screen. Throughout the merger process, the operation is gradual.

Automatic process:

When press button of “Auto”, vacuum, inert gas, heating, strong magnetic mixing, vacuum, casting, vacuum with pressure, cooling, all processes done by one key mode.

Regardless of the type and quantity of gold, silver, and alloy, the frequency and power are modulated. Once the molten metal reaches the casting temperature, the computer system adjusts the heating and emits a low-frequency pulses to sense the stirring alloy. When all set parameters are reached and the temperature stabilizes at the maximum deviation at ± 4°C, the casting starts automatically, followed by a strong pressurization of the metal with an inert gas.

TVC series casting machine is one of the most innovative in the latest generation of pressure vacuum casting machine in the world market.

They use medium-frequency generators, and the power control is proportional and is managed entirely by a computer.

The operator simply puts the metal into the crucible, places the cylinder and presses the button!

The "TVC" series model comes with a 7-inch color touch screen.

Throughout the merger process, the operation is gradual.

Regardless of the type and quantity of gold, silver, and alloy, the frequency and power are modulated.

Once the molten metal reaches the casting temperature, the computer system adjusts the heating and emits a low-frequency pulses to sense the stirring alloy.

Technical data:

| Model No. | HS-VCT3 | |

| Voltage | 380V, 50/60Hz, 3 Phase | |

| Power | 15KW | |

| Capacity (Gold) | 3kg | |

| Melting speed | 2-3 min. | |

| Max. Temperture | 1500°C | |

| Thermocouple | K type | |

| Temp Accuracy | ±1°C | |

| Casting pressure | 0.1-0.3Mpa (Adjust.) | |

| Vibration system | Avaiable | |

| Max. flask size | 5"x16" (5"x12" standard) | |

| Application | Gold, Silver, Copper, alloys | |

| Inert gas | Agron / Nitrogen | |

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |

| Control system | Taiwan WEINVIEW + Siemens PLC intelligent control system (Automatic casting) | |

| Cooling type | Running water or water cooling system | |

| Vacuum pump | High quality vacuum pump included | |

| Dimensions | 750*850*1300mm | |

| Weight | approx. 280kg | |

FEATURES AT A GLANCE

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines. Welcome to visit our factory.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry.

Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115