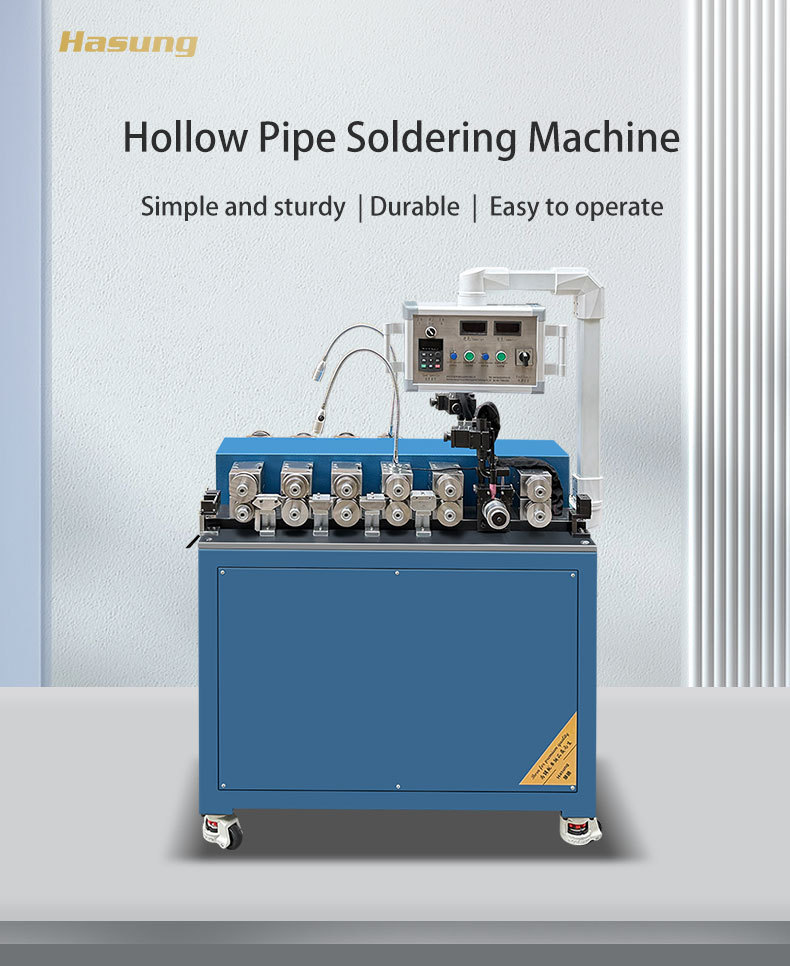

Hasung - Double Head Pipe Welding Machine for Gold Silver Jewellery

Double head welding pipe machine, designed specifically for pipe diameters of 4-12mm, with dual head synchronous operation for efficient welding. Precision rollers and intelligent temperature control ensure uniform and firm welds, suitable for various small diameter pipes, small footprint, easy operation, and assist in efficient production of small diameter pipe welding.

HS-1171

Hasung Double Head Welded Pipe Machine is specially designed for welding small diameter pipes with a diameter of 4-12mm. It is a professional welding equipment that combines efficiency, precision, and reliability.

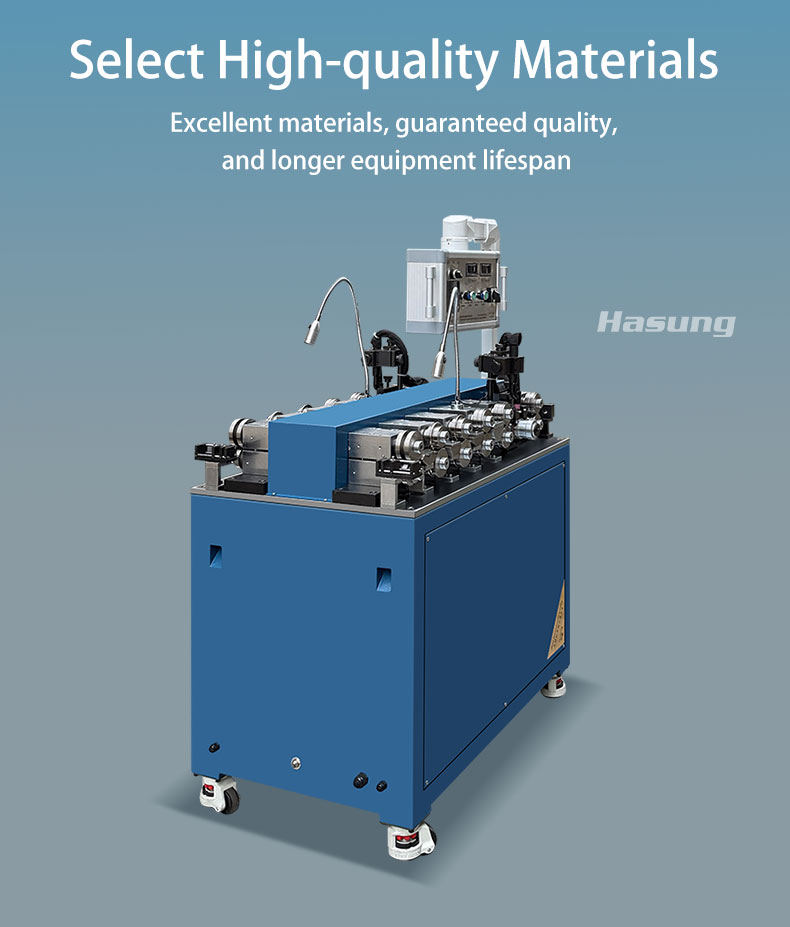

Appearance and Structure: The overall design adopts a calm and atmospheric blue body, with simple and smooth lines, which not only gives a professional and reliable impression visually, but also has good corrosion resistance and wear resistance. The bottom is equipped with flexible brake wheels, which facilitate the movement and fixation of equipment in the workshop and meet the production needs of different workstations. The compact and reasonable structural layout allows the equipment to occupy less space and adapt to various workshop environments.

Core performance:

Double head efficient welding: The unique double head welding design allows for welding operations on both ends of two pipes simultaneously. Compared to single head welding machines, the production efficiency is doubled, greatly shortening the processing cycle and helping enterprises increase production capacity, seizing the opportunity in the fiercely competitive market.

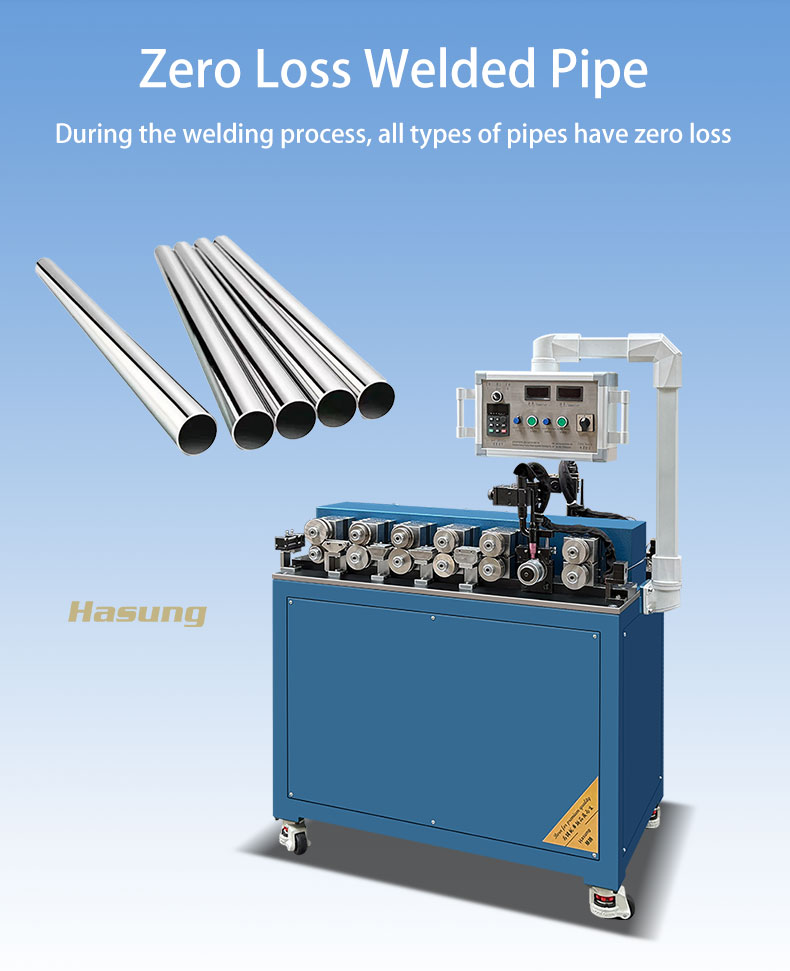

Precise welding control: With advanced mechanical transmission systems and precise welding processes, it is possible to accurately weld pipes within the diameter range of 4-12mm, ensuring that each weld seam is uniform and firm, and the welding quality meets high standards. Both thin-walled and thick walled pipes can achieve stable and reliable welding results, effectively reducing the defect rate.

Stable operation guarantee: The key components of the equipment are made of high-quality materials and exquisite manufacturing processes, with excellent stability and durability. Even in long-term continuous operations, it can still maintain a stable working state, reduce downtime due to malfunctions, and provide strong support for the continuous production of enterprises.

Operation and Control: Equipped with a user-friendly interface and intelligent control system, operators only need to undergo simple training to become proficient. Through the control panel, welding parameters such as welding current, welding speed, welding time, etc. can be easily set to meet the personalized needs of different pipes and welding processes.

| Model | HS-1171 |

|---|---|

| Voltage | 380V/50, 60HZ/3-phase |

| Power | 2.2KW |

| Welded pipe diameter range | 4-12mm |

| Application materials | gold/ silver/ copper |

| Welding gas type | Argon |

| Equipment size | 1120 * 660 * 1560mm |

| Weight | 496kg |

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115