Hasung - Double Head Diamond Cutting Machine for Hollow Ball

The dual head bead machine is like a precision industrial elf, demonstrating extraordinary strength in the field of automotive bead production. It has a compact appearance but contains powerful energy, with two symmetrically distributed working heads that work in sync like skilled craftsmen's hands.

Model No.: HS-1174

Technical Parameter:

Voltage: 220V, single phase

Total power: 2KW

Speed: 24000 rpm

Application metals: gold, silver, copper (hollow ball)

Processing ball diameter: 3.5-8mm

Air pressure: 0.5-0.6Mpa

Dimensions: L1050×W900×H1700mm

Equipment weight: ≈ 1000kg

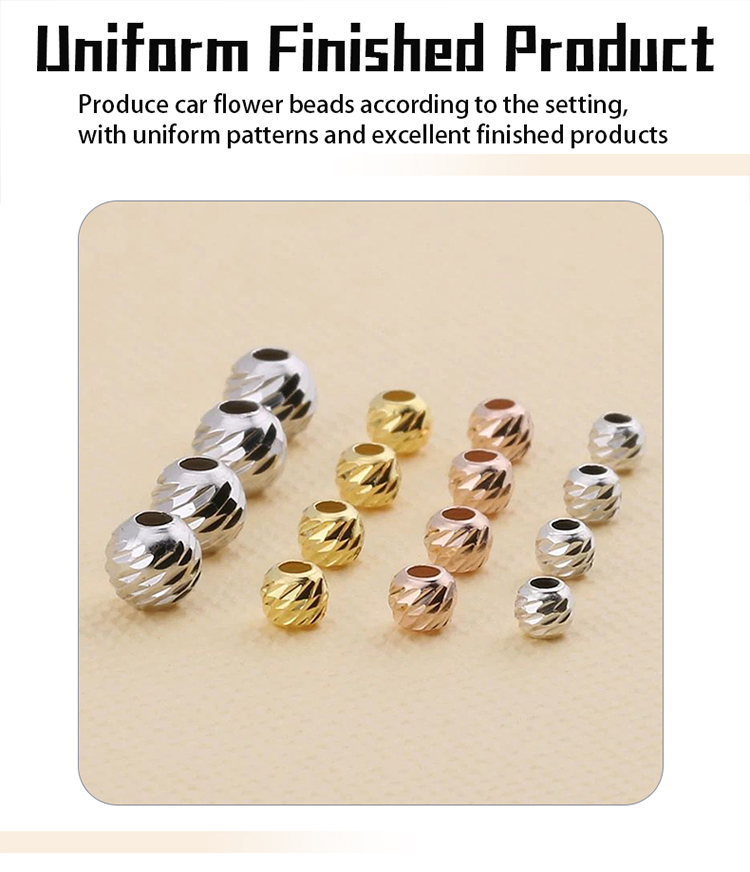

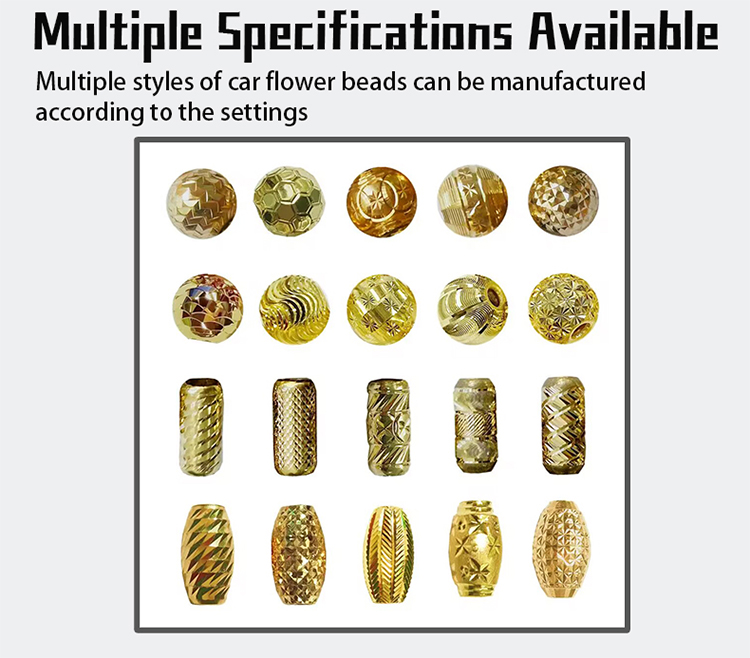

Turn on the device, the motor drives the working head to run at high speed, and the specially made cutting tool precisely carves on the metal billet. Whether it's classic retro spiral patterned beads, fashionable and dynamic diamond patterned beads, or delicate fish scale patterned beads, the dual head bead machine can easily handle them. It strictly follows the preset program to accurately control the depth and rotation angle of the cutting head, ensuring that the size of each car flower bead is precise and error free, with a smooth surface like a mirror and clear and exquisite patterns. At the same time of efficient production, stable output of high-quality products, continuously providing diversified and personalized bead choices for the automotive decoration industry.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115