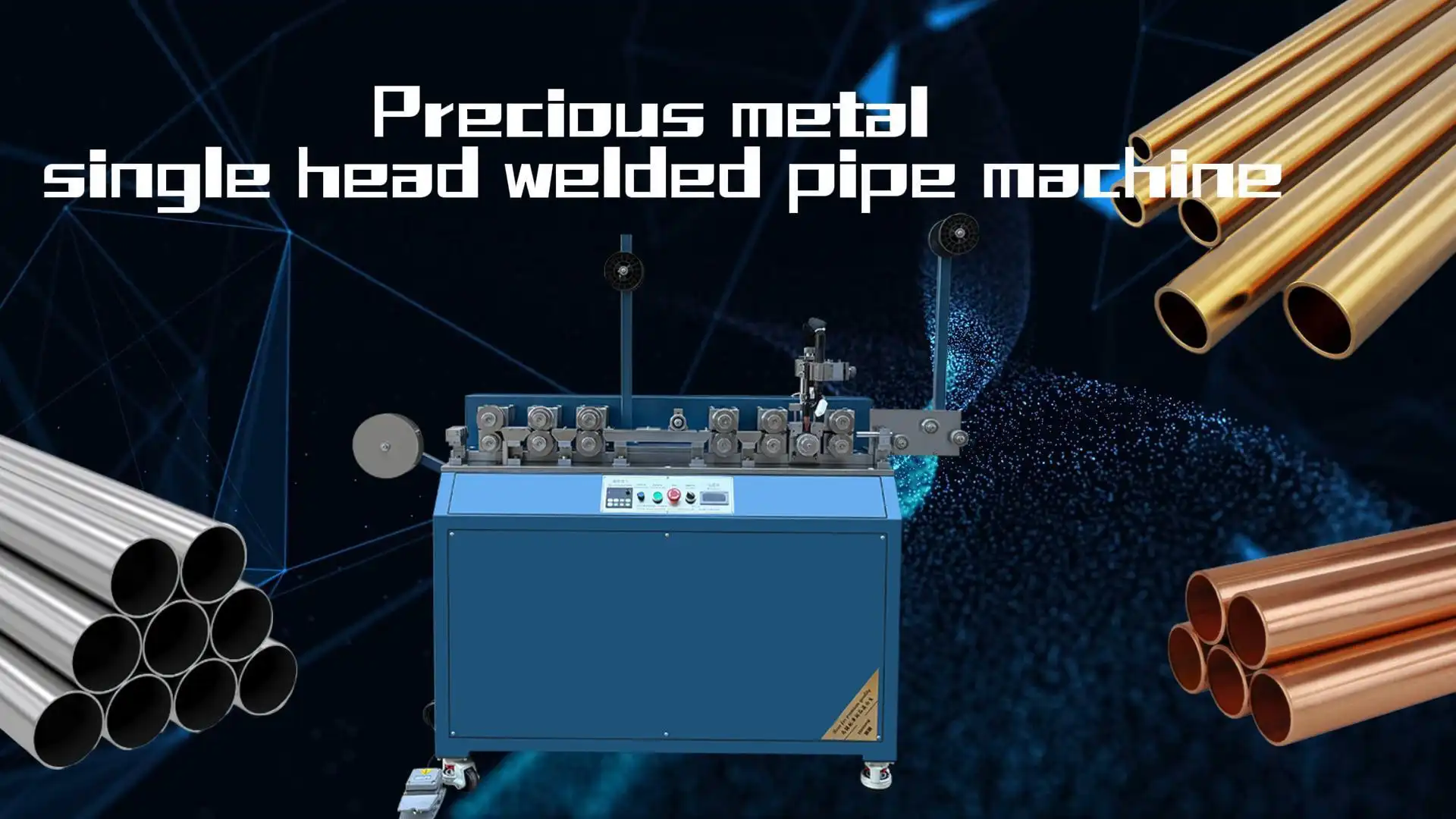

Hasung - Single Head Welded Pipe Machine With The Diameter Of 3.5-12mm

Product Description

Convenient Operation and Precise Contlro

This single-head welded pipe machine features user-friendly "one-touch start" operation. Its clearly arranged control panel integrates functional keys for speed adjustment, current control, and automatic welding, enabling precise parameter settings based on the melting characteristics of metals such as gold, silver, and copper. Equipped with a foot pedal control and an automatic feeding system, it is suitable for both small-batch customization in jewelry workshops and mass production. Beginners can operate it quickly with minimal training.

Zero-Loss Process and Compatibility with Composite Pipes

Utilizing an integrated precision roll-forming and single-head welding technology, it achieves seamless cladding for composite pipes such as gold-clad silver, silver-clad gold, and copper-clad aluminum. The welding process generates no material waste, with fine weld points that preserve the luster of precious metals. It stably processes thin pipes with diameters ranging from 4–12 mm, perfectly meeting the technical requirements for composite materials in jewelry and accessory applications.

Durable Quality and Broad Adaptability

The machine body is constructed from high-hardness alloy materials, with core roll-forming and welding components designed for wear resistance and durability, significantly extending the equipment's service life. It is compatible with various metal materials, including gold, silver, and copper, maintaining consistent precision in processing—whether for cladding precious metals with base materials or fabricating single-metal pipes. This makes it a practical and cost-effective solution for small to medium-sized workshops aiming to reduce costs and improve efficiency.

Product Data Sheet

| Product Parameters | |

| Model | HS-1168 |

| Voltage | 380V/50, 60Hz/3-phase |

| Power | 2.2W |

| Applied Materials | gold/silver/cooper |

| Diameter of welded pipes | 4-12 mm |

| Equipment size | 750*440*450mm |

| weight | about 250kg |

Product advantages

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115