High-End Goldsmith Rolling Machine

Product features

The High-End Goldsmith Rolling Machine is a top-of-the-line wire drawing machine designed for reducing wire sizes for gold, silver, copper, platinum, and more. With 12 channels for wires passing through dies and the capability to input up to 24 dies at a time, this machine ensures precise and efficient wire processing. It features a wire winder device for easy handling and comes with a cover for added safety. With its highest quality construction and automatic liquid cooling, this machine offers reliable performance and durability.

We serve

At our store, we serve craftsmen and jewelry makers looking to elevate their creations with our High-End Goldsmith Rolling Machine. Our top-of-the-line machine is designed to provide precision and efficiency, allowing users to effortlessly roll out thin sheets of metal with ease. We serve our customers by offering a reliable and durable product that enhances the quality of their work. With our High-End Goldsmith Rolling Machine, artisans can achieve seamless results and bring their visions to life. Trust us to serve you with a product that exceeds expectations and helps you unlock your creative potential.

Enterprise core strength

We serve those who value precision and quality craftsmanship with our High-End Goldsmith Rolling Machine. Crafted with advanced technology and expertise, our rolling machine offers unmatched performance and durability for professional jewelers and goldsmiths. From seamlessly rolling out intricate designs to creating perfectly shaped gold or silver sheets, our machine ensures precision and consistency in every use. We serve our customers with a commitment to excellence, providing them with the tools they need to elevate their craft and create stunning pieces of jewelry. Join us in our mission to serve the jewelry industry with the finest equipment available.

Product Introduction

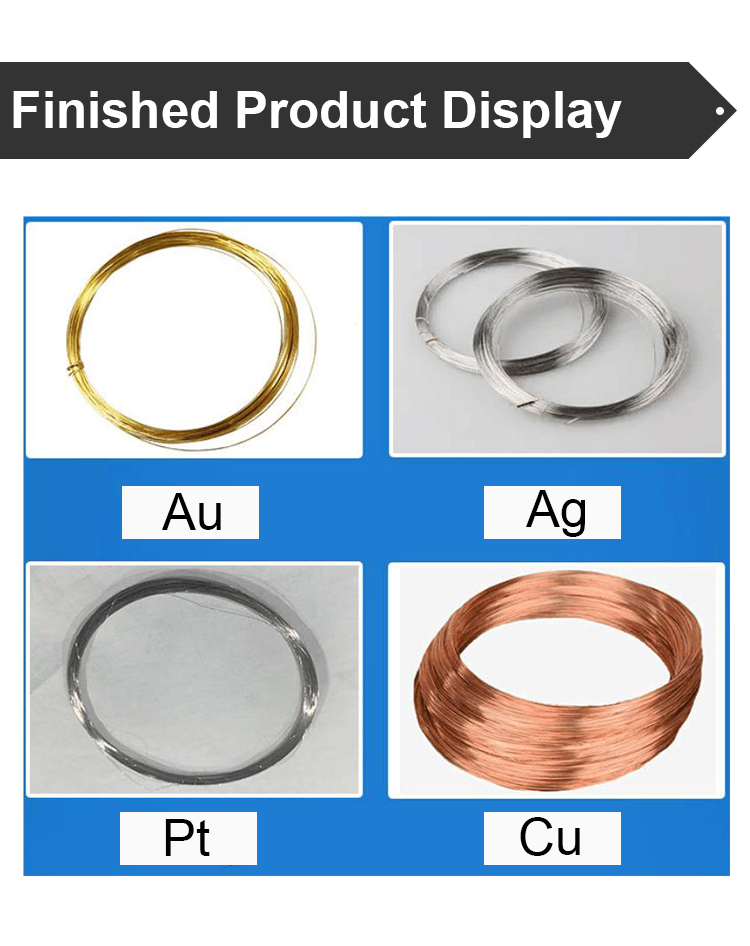

Wire drawing machine is application for reducing wire sizes for gold, silver, copper, platinum,etc. The machine has 12 channels for wires passing through dies, maximum can be input 24 dies. Wire drawing machine is widely used for gold silver jewellery, precious metals wire processing, and other purposes.

Features

1. 12 pass wire drawing

2. With highest quality

3. Wire winder device included

4. With cover

Specification

| Model No. | HS-1123 |

| Voltage | 380V, 3 phase, 50/60Hz |

| Power | 3.5KW |

| Fastest Speed | 55 meters / minute |

| Capability | 1.2mm - 0.1mm; maximum can place 24 dies at a time. |

| Cooling way | Automatic liquid cooling |

| Wire dies | customized (sold separately) |

| Machine size | 1620*780*1280mm |

| Weight | Approx. 380kg |

Company Advantages

Frequently Asked Questions about goldsmith mill

More FAQs

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

About Hasung

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115