High Performance Horizontal Wire Rolling Mill

Product advantages

Our High Performance Horizontal Wire Rolling Mill boasts cutting-edge technology and precision engineering, ensuring top-notch production quality. With a focus on durability and efficiency, this machine is designed to handle heavy workloads with ease. Its advanced features allow for smooth operation and increased productivity, making it a standout choice for businesses looking to enhance their wire production processes.

Company profile

With a strong emphasis on innovation and precision, our company prides itself on producing high-performance horizontal wire rolling mills. Our cutting-edge technology and extensive industry experience have made us a leader in the field, consistently delivering top-quality products that meet the highest standards. We are dedicated to providing our customers with reliable and efficient equipment that enables them to enhance their manufacturing processes and increase productivity. Trust in our expertise and commitment to excellence to take your production capabilities to the next level. Experience the difference with our high-performance horizontal wire rolling mills.

Why choose us

Our company is a leading manufacturer of high-performance horizontal wire rolling mills, delivering precision and efficiency to our customers. With years of experience in the industry, we have perfected our craft to produce top-quality machinery that meets the demands of modern wire production. Our commitment to innovation and excellence drives us to continually improve and adapt to the ever-changing needs of the market. We pride ourselves on our reliable products, exceptional customer service, and dedication to customer satisfaction. Trust us to provide you with the best wire rolling mill solutions for your business.

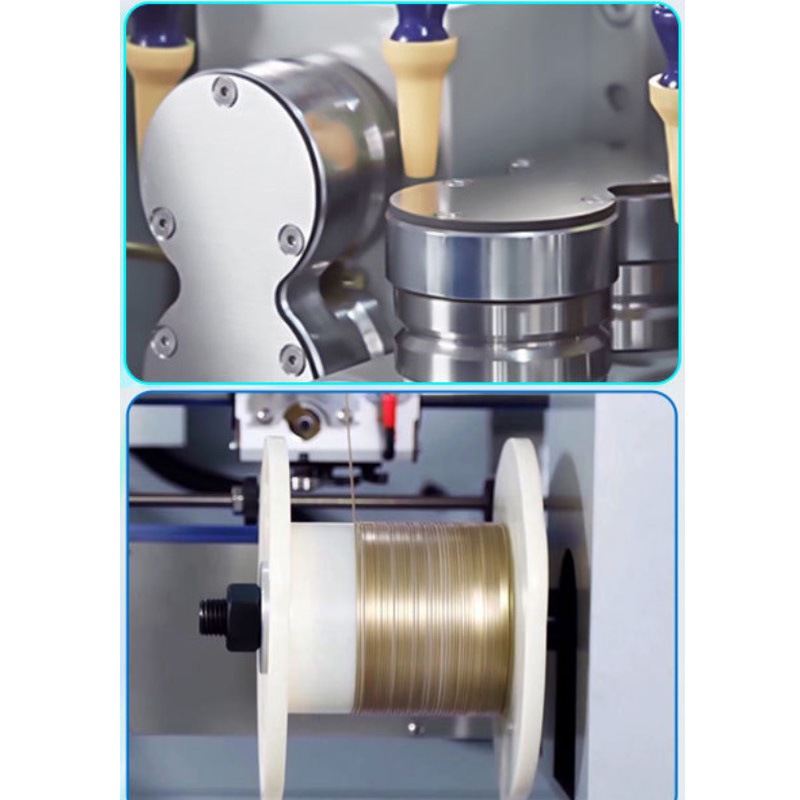

Hasung’s horizontal continuous jewelry metal wire rolling mill is a fully integrated and servo-driven line engineered for uninterrupted, precision reduction of precious and non-ferrous wires. The system begins with a motorized payoff that maintains constant back-tension, feeding wire through a series of horizontally arranged rolling stands. Each stand houses tungsten-carbide rollers mounted on precision bearings; the rollers are water-cooled and mirror-polished to guarantee uniform gauge, near-zero ovality and a bright surface finish without secondary pickling or polishing.

Tehnical Data:

| Model No. | HS-HWRM |

| Voltage | 380V, 50Hz, 3 Phases |

| Power | 11KW |

| Roller diameter | 96mm(Roller material: SKD11) |

| Roller quantity | 20 pairs |

| Processing material range | input 6.0mm round wire, 5.0mm square wire; output 1.1x1.1mm |

| Max rolling speed | 75 m/min. |

| Application metals | Gold, K-gold, Silver, Copper, alloy. |

| Dimensions | 2800x900x1300mm |

| Weight | approx. 2500kg |

| Control system | frequency speed control, motor drive rolling |

| Wire collection way | Sagging Gravity take-up |

| Material cooling | Spray lubricating fluid cooling; |

Advantages

1.Continuous rolling from ingot to spool cuts downtime and labor.

2.Servo-controlled carbide rollers hold micron-grade tolerance & mirror finish.

3.PLC recipes allow instant material changeovers without trial runs.

4.Water-cooled closed-loop system cools rolls, reclaims coolant, slashes waste.

5.Quick-swap cassettes swap in minutes, maximizing uptime during multi-shift ops.

Machine Operation Process

1.Feeding & Payoff

A powered payoff reel unwinds the incoming rod or coil under controlled back-tension, ensuring the wire enters the first stand straight and without kinks.

2.Continuous Rolling Stands

Horizontally arranged pairs of tungsten-carbide rollers reduce the wire in successive passes. Each stand is servo-driven and water-cooled; the rollers compress and elongate the metal while maintaining a bright, uniform surface.

3.Real-Time Closed-Loop Control

A PLC with frequency-speed control monitors diameter, tension and temperature via laser gauges and load cells. If any parameter drifts, the gold wire rolling machine system instantly adjusts roll gap, motor speed or coolant flow to keep the profile within tolerance .

4.Cooling & Lubrication

A fine spray of lubricating coolant is applied between stands. The fluid removes heat, reduces friction and is continuously filtered so the shop floor stays dry and the rollers last longer.

5.Sagging Gravity Take-up

After the final pass, the finished wire drops into a sagging gravity take-up system that coils it neatly onto a spool without stretching or surface marring.

6.Recipe Recall & Changeover

All settings for gold, silver, copper or alloy recipes are stored in the HMI. Operators simply select the next recipe and swap roller cassettes; the mill restarts in minutes.

Product Information

About Hasung

Shenzhen Hasung Precious Metals Equipment Co., Ltd. is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry. Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc. Our mission is to build the most innovative heating and casting equipment for precious metal manufacturing and gold jewellery industry, providing customers with the highest reliability in your daily operations and the best quality. We are acknowledged in the industry as a technology leader. What we're deserved to be proud is our vacuum and high vacuum technology is the best in China. Our equipment, manufactured in China, is made of highest-quality components, apply worldwide famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc. Hasung has proudly served the precious metal casting & forming industry with vacuum pressure casting equipment, continuous casting machine, high vacuum continuous casting equipment, vacuum granulating equipment, induction melting furnaces, gold silver bullion vacuum casting machine, metal powder atomizing equipment, etc. Our R & D department is always working on developing casting and melting technologies to suit our ever changing industry for the New Materials industry, Aerospace, Gold Mining, Metal Minting Industry, Research laboratories, Rapid Prototyping, Jewellery, and Artistic Sculpture. We do provide precious metals solutions for customers. We uphold the principle of "integrity, quality,cooperation, win-win" business philosophy,committed to creating first-class products and services. We always believe that technology changes the future. We specialize in designing and developing custom finishing solutions. Committed to provide precious metal casting solutions, coin minting solution, platinum, gold and silver jewellery casting solution, bonding wire making solution, etc. Hasung is looking for partners and investors for precious metals to develop technological innovation bringing outstanding return on investment. We are a company who only makes high end quality equipment, we don't take price as priority, we take value for customers.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115