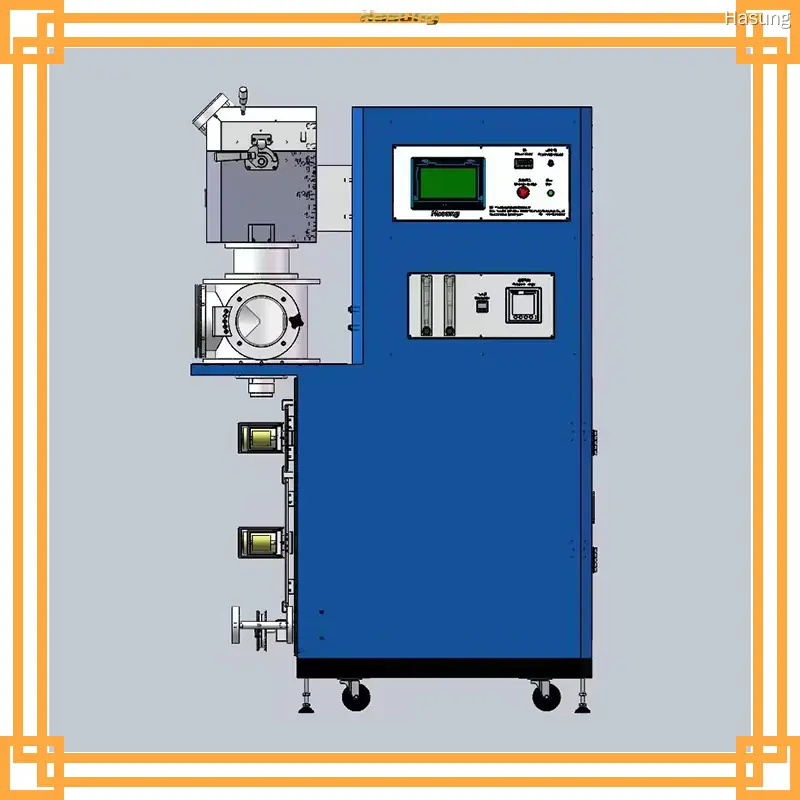

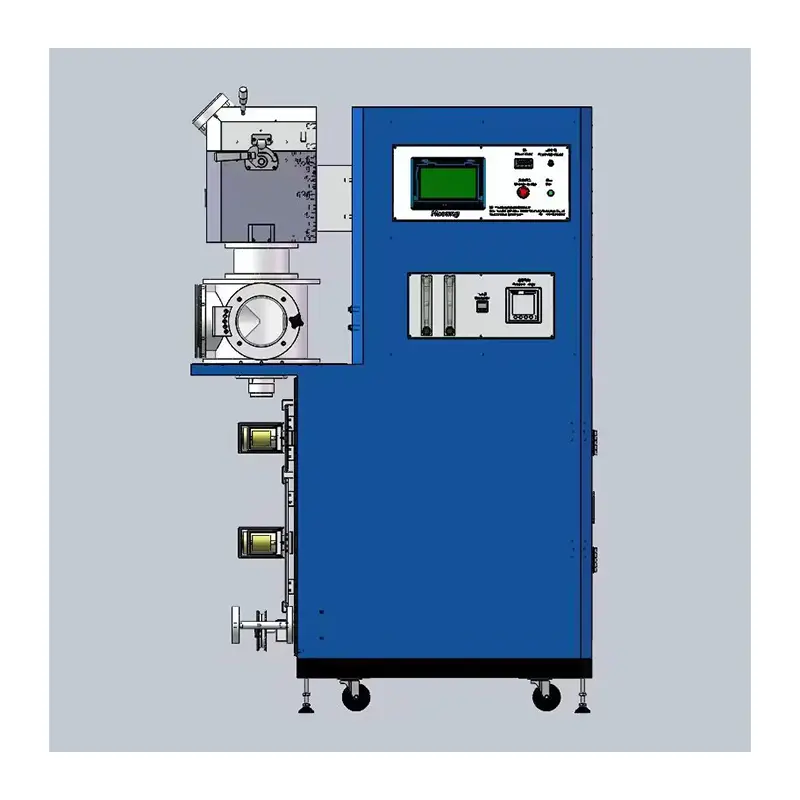

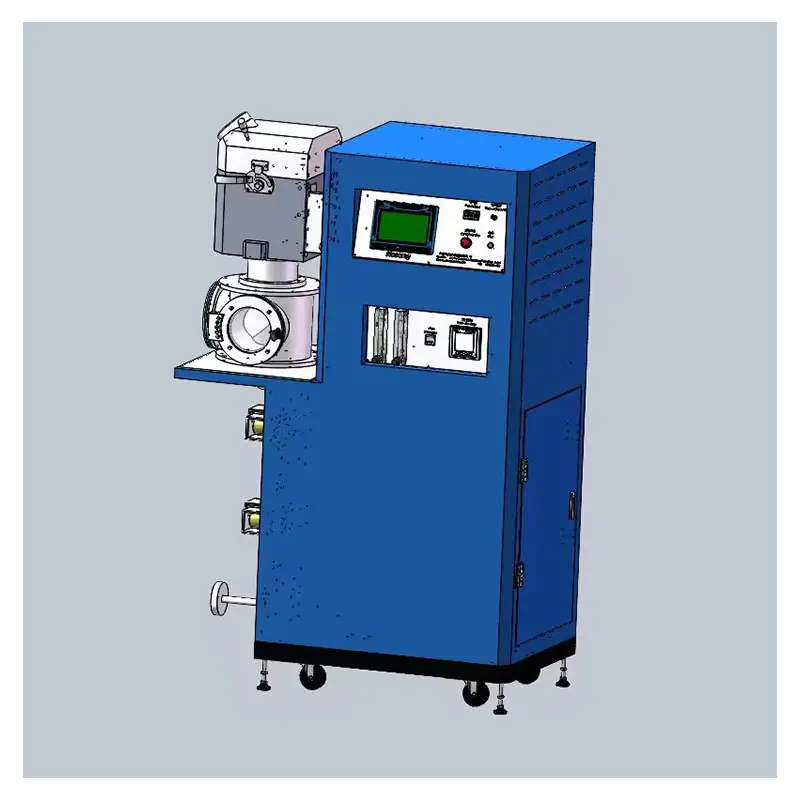

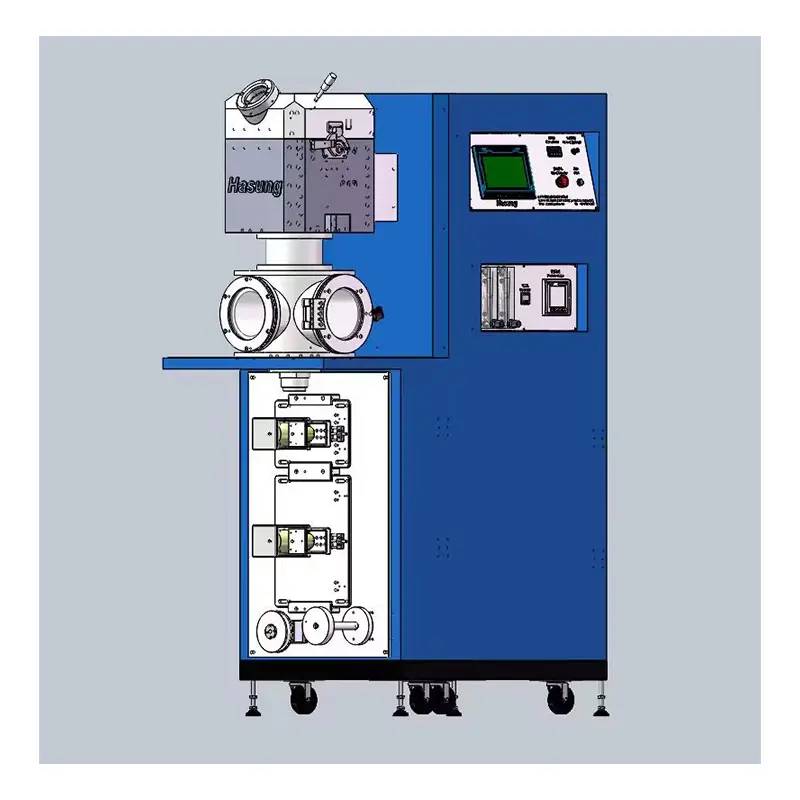

High-Quality Metal Vacuum Continuous Casting Machine for Precious Metals

Imagine a modern workshop where shimmering streams of molten gold and silver flow effortlessly through the air, as if nature itself is crafting a masterpiece. Our High-Quality Metal Vacuum Continuous Casting Machine transforms precious metals into flawless bars, capturing their radiant beauty while ensuring maximum purity, all within a sleek, high-tech design that glistens like the treasures it produces. Witness the enchanting dance of innovation and artistry, where each pour not only creates value but also tells a story of craftsmanship that elevates your creations to a realm of unparalleled excellence.

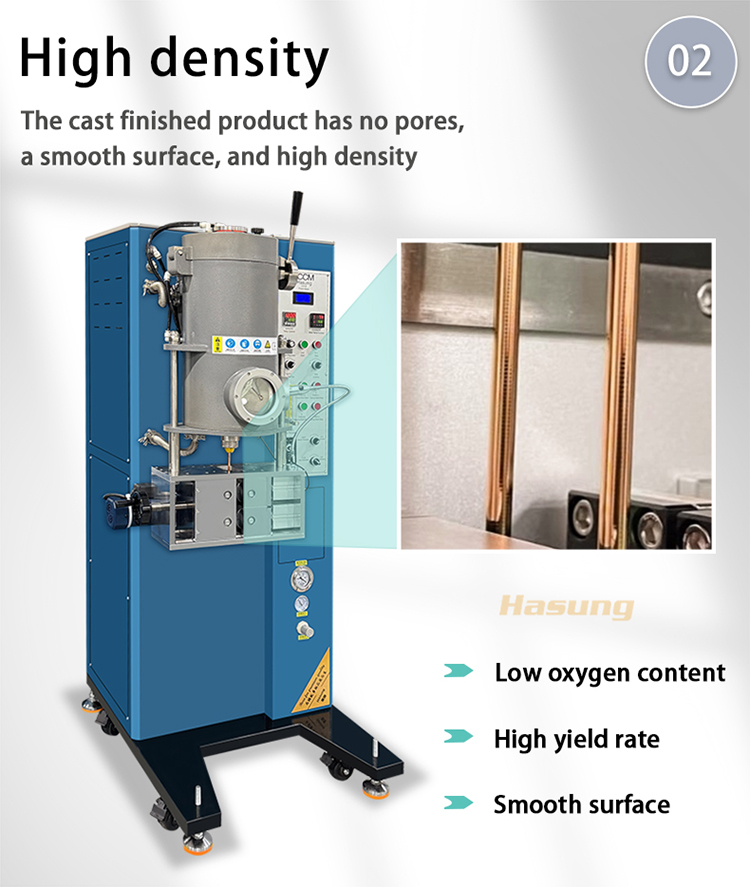

Product features

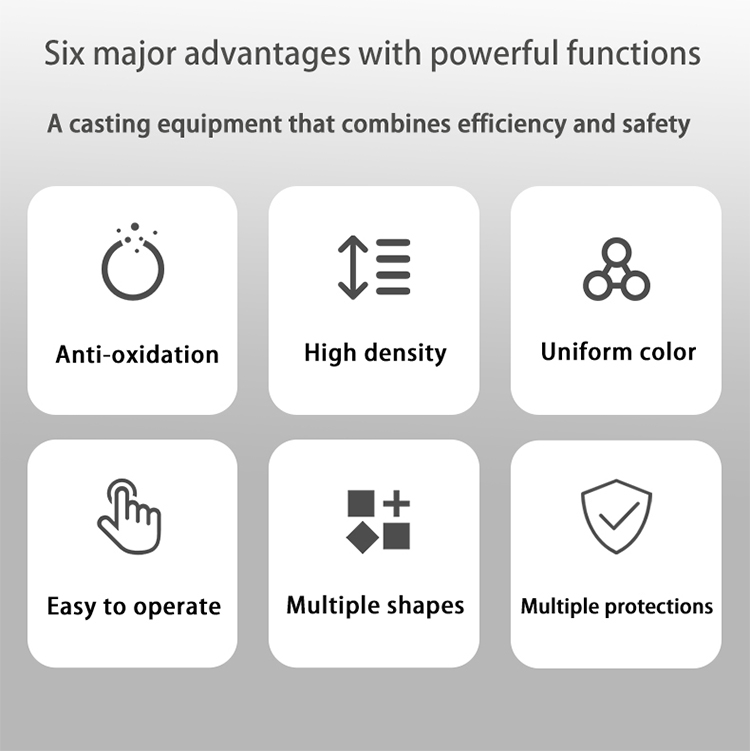

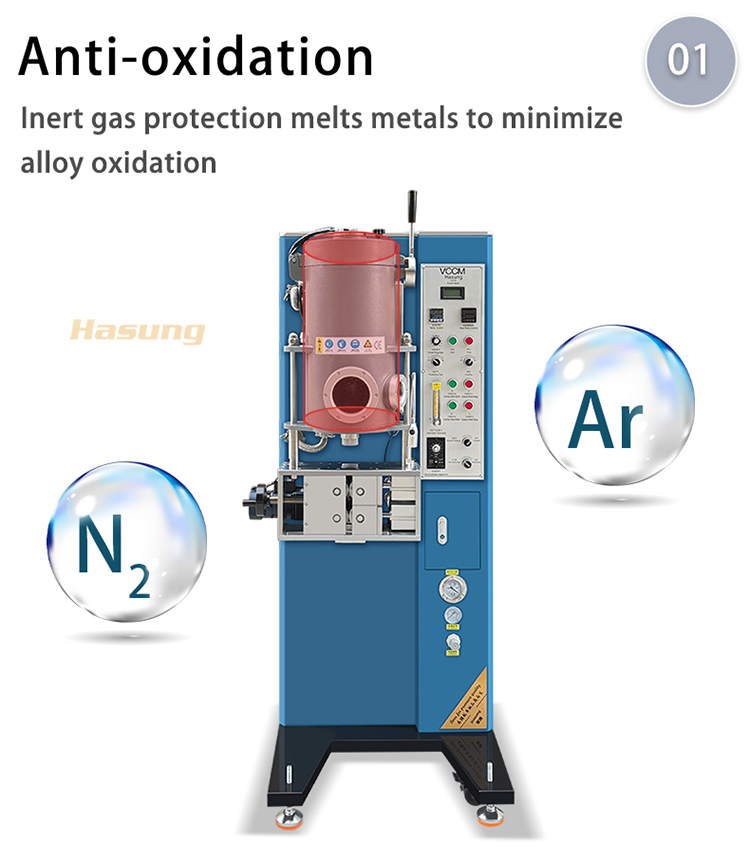

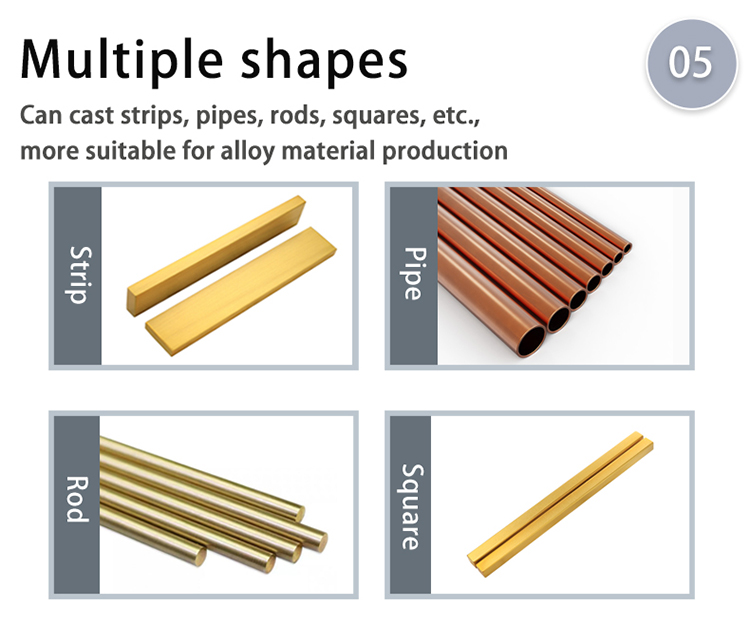

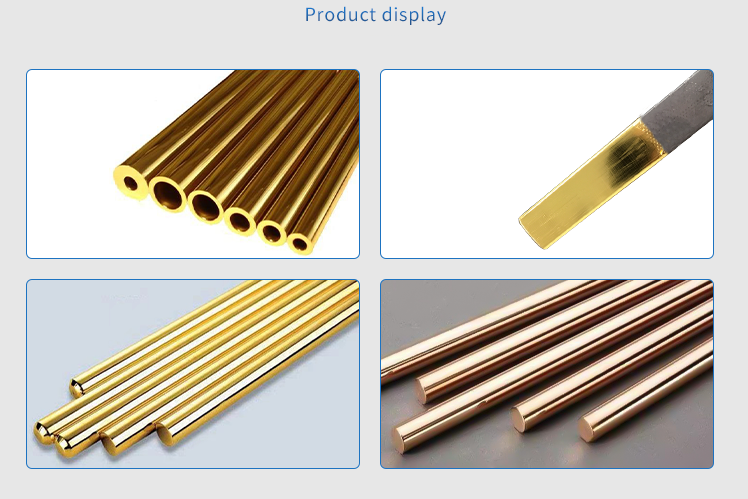

The High-Quality Metal Vacuum Continuous Casting Machine for Precious Metals is engineered for precision, offering an impressive melting capacity of up to 10 kg for gold, silver, and copper, along with a maximum temperature of 1500°C. This jewelry continuous casting machine features a foolproof one-key operation and advanced Taiwan/Siemens PLC controls, ensuring consistent quality and user-friendly experience in producing high-purity rods and sheets with excellent temperature accuracy of ±1°C. Built with top-tier components and a robust cooling system, it not only guarantees reliable performance for various precious metals applications but also aligns with international quality standards, making it a premium choice for metal refining and jewelry manufacturing.

Team strength

**Team Strength:**

At the heart of our High-Quality Metal Vacuum Continuous Casting Machine lies a dedicated team of experts committed to excellence. Our skilled engineers and technicians bring decades of experience in metal processing and casting technology, ensuring that every machine meets the highest industry standards. Our collaborative approach fosters innovation, enabling us to tailor solutions that meet the unique needs of our clients in the precious metals sector. We prioritize continuous training and development, ensuring our team stays ahead of industry trends. Together, we are devoted to enhancing performance, reliability, and efficiency, empowering your operations with unmatched quality and precision.

Why choose us

**Team Strength**

At the heart of our High-Quality Metal Vacuum Continuous Casting Machine for Precious Metals is a dedicated team that embodies expertise, innovation, and collaboration. Our engineers, designers, and support staff are industry veterans, bringing years of experience in metallurgy and casting technology. We prioritize teamwork and continuous development, ensuring that our product evolves with the latest advancements. This synergy not only enhances the machine's performance and reliability but also guarantees exceptional customer support. Together, we are committed to achieving excellence, providing our clients with cutting-edge solutions that elevate their production capabilities and ensure the highest standards in precious metal casting.

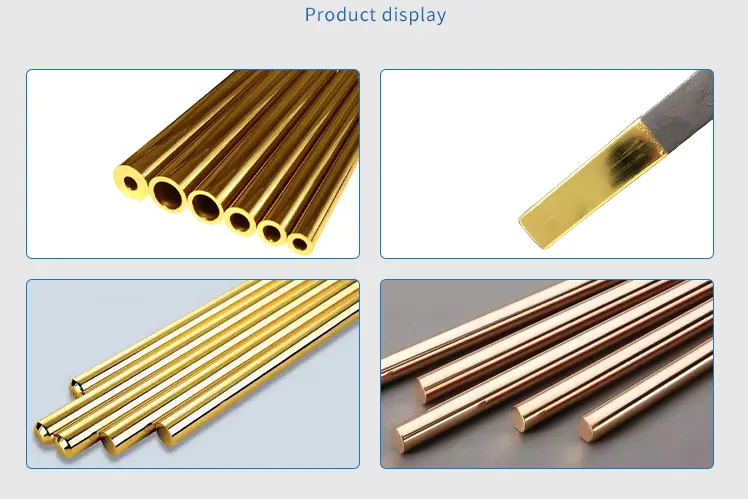

High Quality Vacuum Continuous Casting Machine for Making High Purity Copper Gold Silver Rods, Sheets.

Technical data:

| Model No. | HS-VCC4 | HS-VCC5 | HS-VCC6 | HS-VCC8 | HS-VCC10 |

| Voltage | 380V 3 Phases, 50/60Hz | ||||

| Power | 15kW | 15kW | 15kW | 20kW | 20kW |

| Capacity (Au) | 4kg | 5kg | 6kg | 8kg | 10kg |

| Max Temp | 1500°C | ||||

| Casting Speed | 200mm-1200mm/min. | ||||

| Casting Rod Diameter | 4mm-20mm | ||||

| Casting product | Rods, sheets, square, etc. | ||||

| Temp Accuracy | ±1°C | ||||

| Temp detector type | PID, K type thermocouple | ||||

| Vacuum Pump | High level degree vacuum pump, vacuum degree (optional) | ||||

| Application metals | Gold, silver, copper and alloys | ||||

| Operation method | Manual key operation | ||||

| Control System | Human-machine interface intelligent control system | ||||

| Cooling type | Water chiller (Sold separately) | ||||

| Dimensions | 800*870*1760mm | ||||

| Weight | approx. 300kg | ||||

Company Advantages

Frequently Asked Questions about metal melting equipment

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

About Hasung

Shenzhen Hasung Precious Metals Equipment Co., Ltd. is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry. Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc. Our mission is to build the most innovative heating and casting equipment for precious metal manufacturing and gold jewellery industry, providing customers with the highest reliability in your daily operations and the best quality. We are acknowledged in the industry as a technology leader. What we're deserved to be proud is our vacuum and high vacuum technology is the best in China. Our equipment, manufactured in China, is made of highest-quality components, apply worldwide famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc. Hasung has proudly served the precious metal casting & forming industry with vacuum pressure casting equipment, continuous casting machine, high vacuum continuous casting equipment, vacuum granulating equipment, induction melting furnaces, gold silver bullion vacuum casting machine, metal powder atomizing equipment, etc. Our R & D department is always working on developing casting and melting technologies to suit our ever changing industry for the New Materials industry, Aerospace, Gold Mining, Metal Minting Industry, Research laboratories, Rapid Prototyping, Jewellery, and Artistic Sculpture. We do provide precious metals solutions for customers. We uphold the principle of "integrity, quality,cooperation, win-win" business philosophy,committed to creating first-class products and services. We always believe that technology changes the future. We specialize in designing and developing custom finishing solutions. Committed to provide precious metal casting solutions, coin minting solution, platinum, gold and silver jewellery casting solution, bonding wire making solution, etc. Hasung is looking for partners and investors for precious metals to develop technological innovation bringing outstanding return on investment. We are a company who only makes high end quality equipment, we don't take price as priority, we take value for customers.

Product Information

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115