High-Tech Wire Drawing Machine for Jewelry Making

Product features

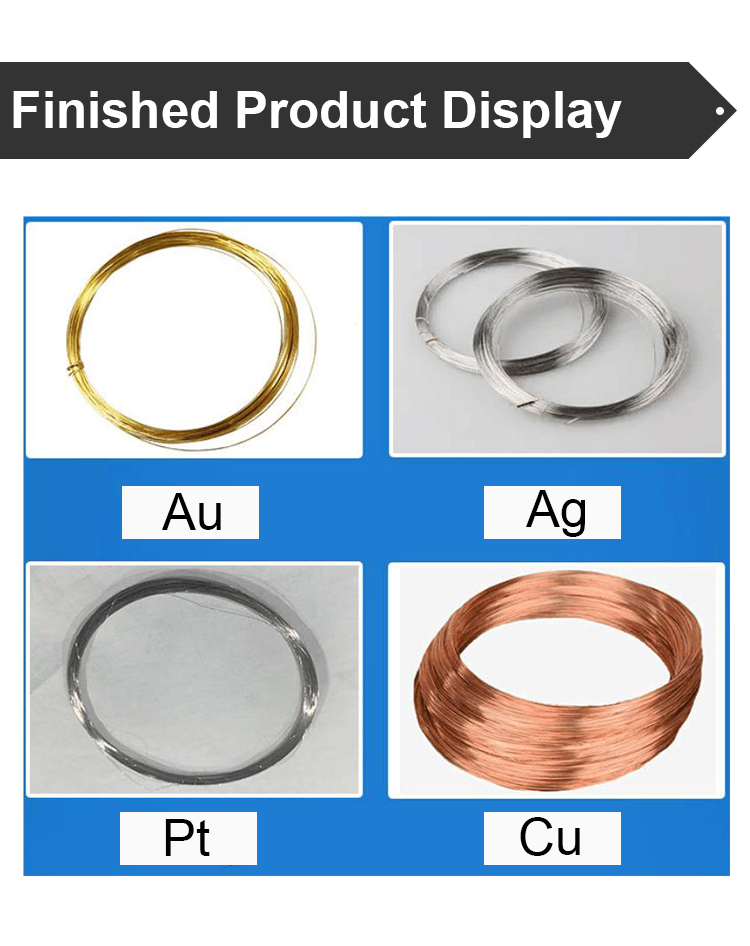

This high-tech wire drawing machine for jewelry making features 12 pass wire drawing with the highest quality standards, including a wire winder device and a protective cover for safety. The machine is designed for reducing wire sizes for gold, silver, copper, platinum, etc., with a maximum capability of 1.2mm to 0.1mm wire thickness and the ability to input up to 24 dies at a time. The rolling mill machine jewelry also comes with automatic liquid cooling and customized wire dies sold separately for a precise and efficient wire processing experience.

Team strength

Team strength is at the heart of our high-tech wire drawing machine for jewelry making. Our dedicated team of engineers, designers, and technicians have combined their expertise to create a state-of-the-art machine that is both efficient and reliable. With a strong emphasis on collaboration and innovation, our team works seamlessly together to ensure that every detail of the machine is meticulously crafted to perfection. By leveraging the diverse skills and talents of our team members, we are able to deliver a product that exceeds expectations and empowers jewelers to create beautiful pieces with ease. Trust in our team's strength to elevate your jewelry making experience.

Why choose us

Team strength is a core attribute of our High-Tech Wire Drawing Machine for Jewelry Making. Our dedicated team of engineers and technicians have worked tirelessly to design a cutting-edge machine that ensures precision and consistency in the wire drawing process. With years of combined experience in the jewelry making industry, our team brings expertise and innovation to every aspect of this machine. Our commitment to quality and customer satisfaction is reflected in the superior performance of our product. Trust in our team's strength to deliver a reliable and efficient wire drawing machine that will take your jewelry making to the next level.

Product Introduction

Wire drawing machine is application for reducing wire sizes for gold, silver, copper, platinum,etc. The machine has 12 channels for wires passing through dies, maximum can be input 24 dies. Wire drawing machine is widely used for gold silver jewellery, precious metals wire processing, and other purposes.

Features

1. 12 pass wire drawing

2. With highest quality

3. Wire winder device included

4. With cover

Specification

| Model No. | HS-1123 |

| Voltage | 380V, 3 phase, 50/60Hz |

| Power | 3.5KW |

| Fastest Speed | 55 meters / minute |

| Capability | 1.2mm - 0.1mm; maximum can place 24 dies at a time. |

| Cooling way | Automatic liquid cooling |

| Wire dies | customized (sold separately) |

| Machine size | 1620*780*1280mm |

| Weight | Approx. 380kg |

Company Advantages

Frequently Asked Questions about goldsmith mill

More FAQs

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

About Hasung

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115