High Vacuum Granulating Machine - Silver Granulation Machine

Product features

The silver granulating machine features Germany IGBT induction heating technology for fast melting, energy efficiency, and environmental protection. It also includes a closed + vacuum/inert gas protection melting chamber to prevent oxidation and impurities, making it suitable for high-purity metal casting. The Mistake Proofing automatic control system and PID temperature control system ensure ease of use and precise temperature control, while using high-quality components from well-known brands for reliable performance.

Team strength

Our High Vacuum Granulating Machine, also known as the Silver Granulation Machine, showcases the strength of our dedicated team. With years of experience and expertise in the industry, our team of engineers and technicians have worked tirelessly to develop a cutting-edge product that guarantees superior performance and reliability. Our team's relentless pursuit of excellence ensures that each machine is meticulously designed and rigorously tested to meet the highest standards of quality. From the core attributes of precision engineering to the value attributes of durability and efficiency, our team's strength shines through in every aspect of the Silver Granulation Machine.

Why choose us

Our High Vacuum Granulating Machine in Silver is built with exceptional team strength to ensure top-notch performance and reliability. Our team of highly skilled engineers and technicians work together seamlessly to design and manufacture this innovative granulation machine. With a strong emphasis on teamwork, our product undergoes rigorous testing and quality control measures to guarantee its efficiency and durability. From the core attributes of precision engineering to the value attributes of enhanced productivity and cost-effectiveness, our team's collective expertise shines through in every aspect of this high vacuum granulating machine. Choose our product for unparalleled team strength and superior performance.

Description

Using Germany IGBT induction heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

2. The closed type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Using a closed + vacuum/inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved.

4. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

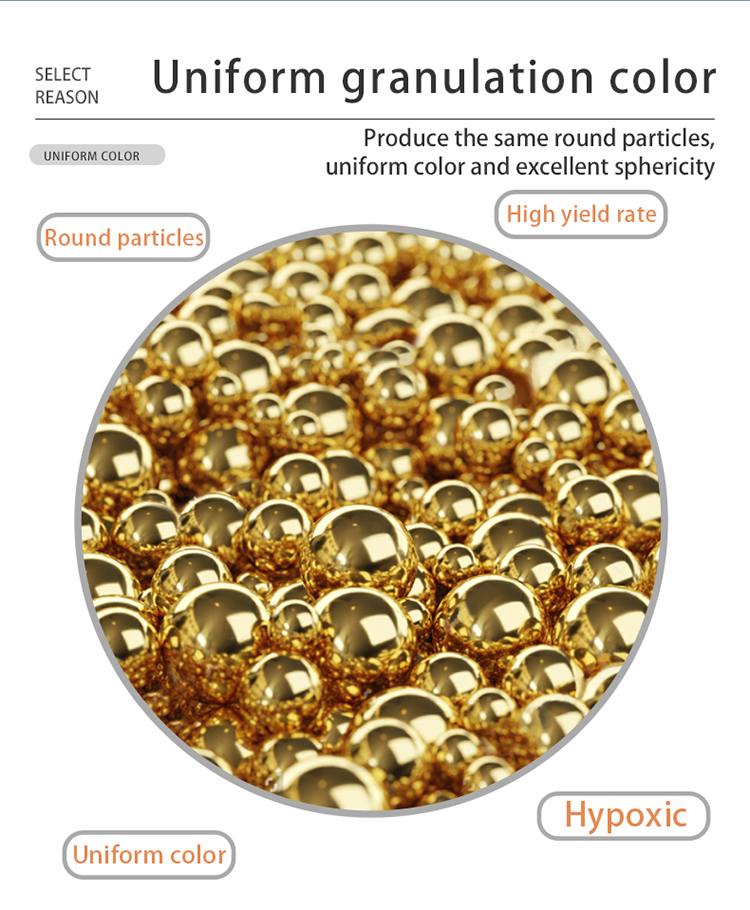

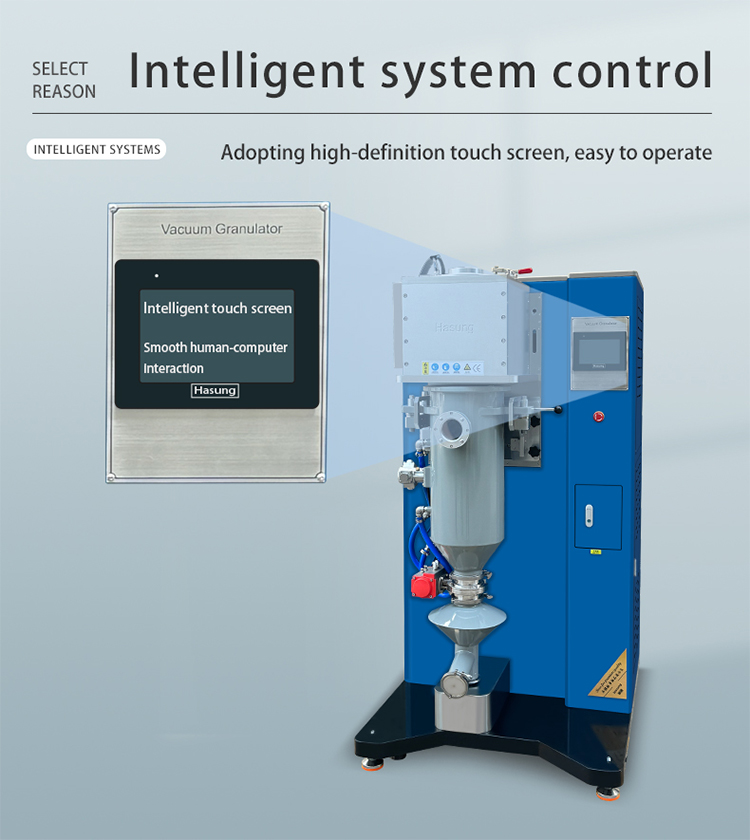

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color. 6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

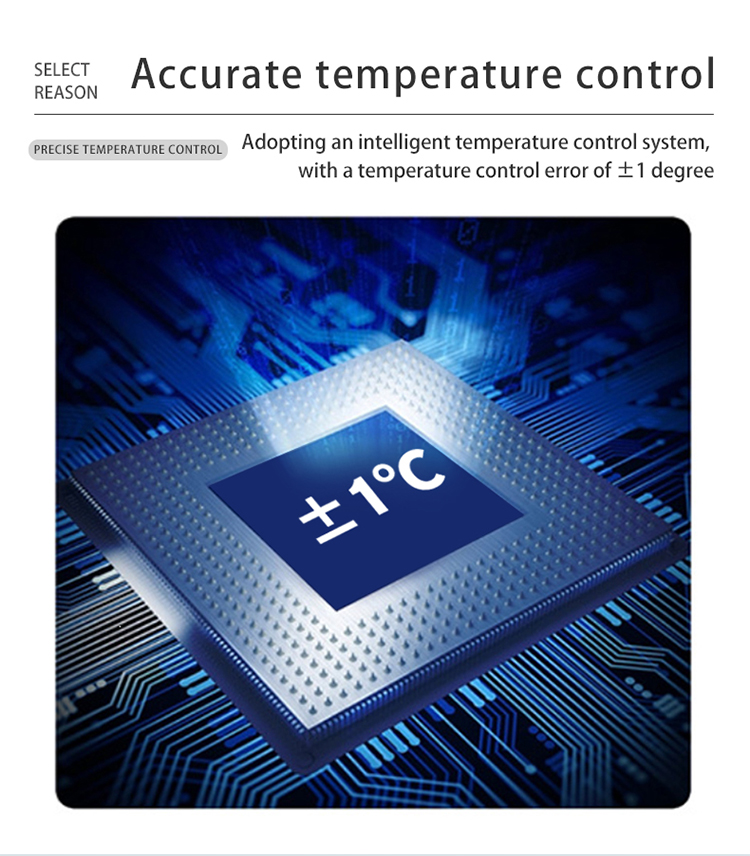

7. Using PID temperature control system, the temperature is more accurate (±1°C). The HS-GR vacuum system casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of gold, silver, copper.

9. This equipment uses Japan SMC pneumatic, IDEC, Shimaden, Germany Omron, Siemens, and other well-known brand components at home and abroad.

10. Melting, electromagnetic stirring, and refrigeration in a closed + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

Technical data

Model No. | HS-VGR20 | HS-VGR30 | HS-VGR50 | HS-VGR100 |

Voltage | 220V, 50/60Hz | 220V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

Power Supply | 0-30KW | 0-30KW | 0-30KW | 0-50KW |

Max Temp | 1500°C | |||

Melting Time | 8-10 min. | 8-15 min. | 10-15 min. | 20-25 min. |

Shielding Gas | Argon / Nitrogen | |||

Temp Accuracy | ±1°C | |||

Capacity (Gold) | 20kg | 30kg | 50kg | 100kg |

Application | Gold, K gold, silver, copper and other alloys | |||

Vacuum | High level degree vacuum pump German Vacuum Pump, Vacuum degree-100KPA | |||

Operation method | Auto mode and manual mode both | |||

Control system | 10" Taiwan Weinview Touch screen + Siemens PLC intelligent control system | |||

Cooling type | Water chiller(sold separately) or Running water | |||

Dimensions | 1150*970*1860mm 1250*970*1950mm | |||

Weight | approx. 450kg approx. 550kg | |||

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115