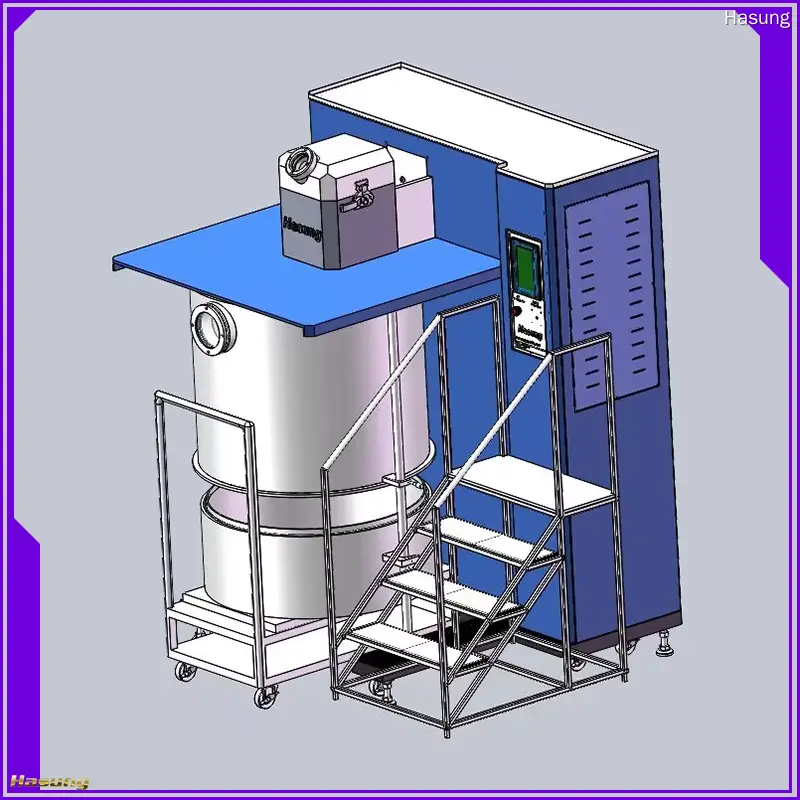

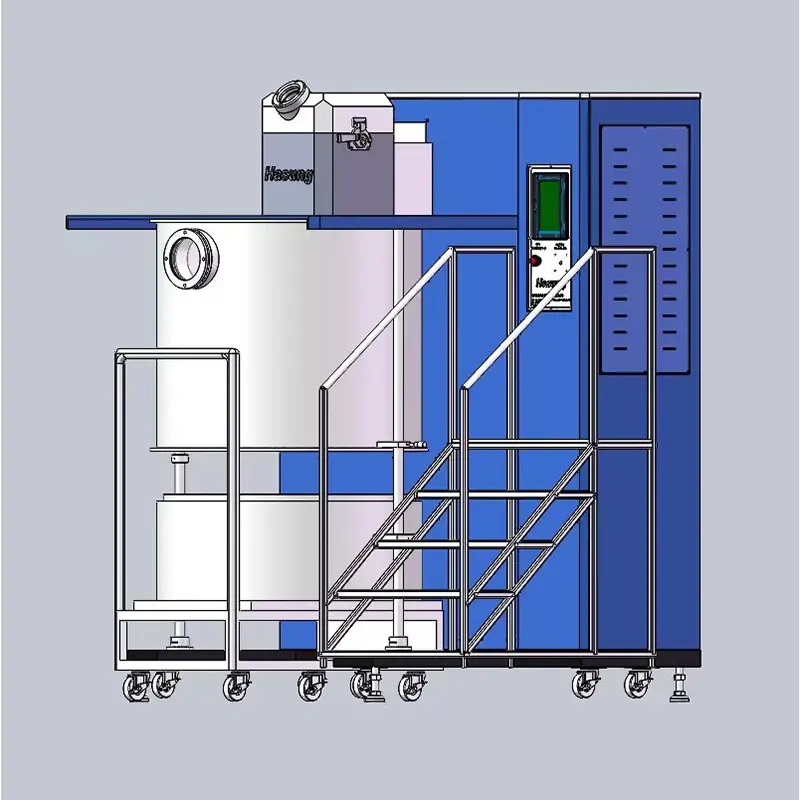

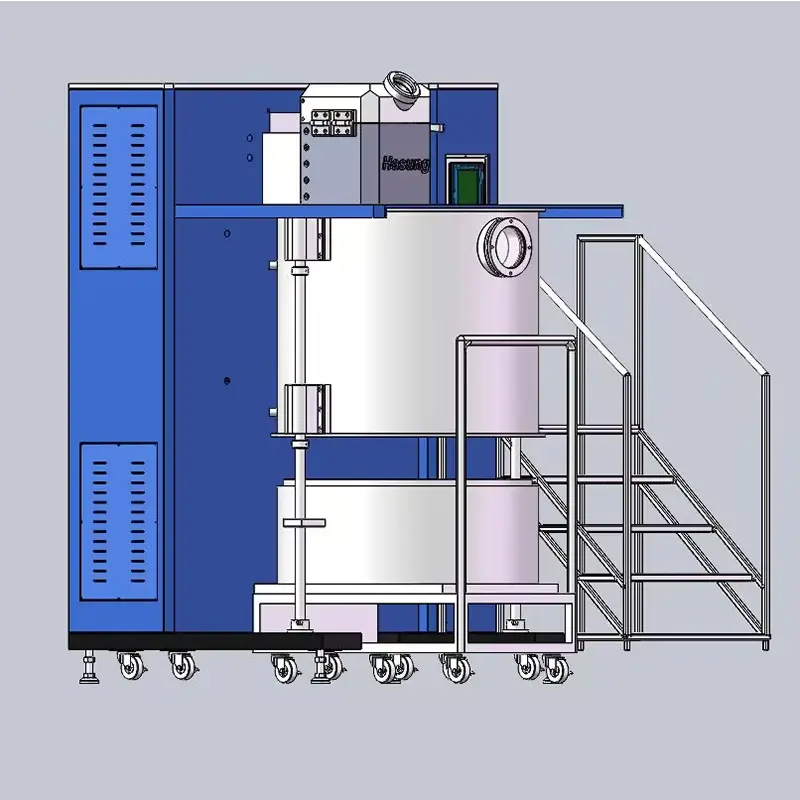

Metal Flakes Machine for Refining Process

Product advantages

Our Metal Flakes Machine for the Refining Process is designed with precision and quality in mind, crafted to effortlessly refine metals with ease. The machine boasts powerful functions that efficiently break down materials into fine metal flakes, ensuring a thorough refining process. With user-friendly features and a durable build, our machine stands out as a reliable and efficient tool for any refining operation.

Team strength

At Metal Flakes Machine, our team strength lies in our deep expertise and collaborative approach to the refining process. With seasoned engineers, skilled technicians, and dedicated support staff, we bring a wealth of knowledge and hands-on experience to every project. Our team's synergy and mutual respect ensure efficient operations and high-quality results. Through clear communication and effective problem-solving, we tackle challenges head-on and deliver innovative solutions that exceed expectations. Together, we are committed to continuously improving our processes and technologies to meet the evolving needs of our customers. Join us at Metal Flakes Machine and experience the power of teamwork in action.

Enterprise core strength

At Metal Flakes Machine, our team strength lies in our combined expertise in refining processes. With years of experience in the industry, our team of specialists works together seamlessly to ensure that our machine delivers top-quality results every time. From designing and manufacturing to customer support, our team is dedicated to providing the best possible experience for our clients. By leveraging our team's diverse skill sets and collaborative spirit, we are able to continuously improve and innovate our product to meet the ever-evolving needs of our customers. Trust in our team strength to take your refining process to the next level.

Technical Specification

| Model No. | HJ-MS5 | HJ-MS8 | HJ-MS30 | HJ-MS50 |

| Voltage | 380V, 50Hz, 3 phases | 380V, 50Hz, 3 phases | 380V, 50Hz, 3 phases | 380V, 50Hz, 3 phases |

| Power | 10KW | 15KW | 30KW | 30KW/50KW |

| Max temperature | 1500 ℃ | 1500 ℃ | 1500 ℃ | 1500 ℃ |

| Melting time | 2-3 min. | 2-5 min. | 4-6 min. | 10-15mim. |

| Protective gas | Argon/Nitrogen | |||

| Application | Gold, silver, copper Alloys (Platinum alloys, palladium alloys) | |||

| Cooling method | Water chiller/Running water | |||

| Flasks thickness | 0.1-0.5mm | |||

| Control system | Taiwan Weinview/Siemens PLC touch Panel | |||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |||

| Dimensions | 1120x1080x1750mm | 1260x1060x1920mm | ||

| 280kg | 400kg | |||

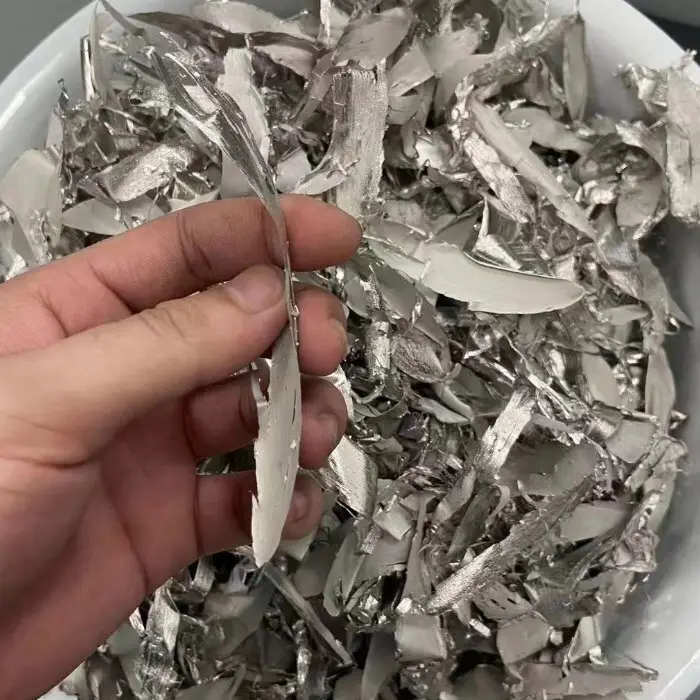

Gold flakes

Platinum flakes

Title: Importance of gold alloy flakes in the refining process

Gold refining is a meticulous process that requires precision and attention to detail. Before the actual refining work can begin, the impure gold must be converted into flakes or powder. This is where sheet metal making machines come into play. In this blog, we will delve into the importance of gold alloy flakes in the refining process and the role of metal flake making machines in achieving this critical step.

Gold alloys are combinations of gold and other metals, often containing impurities that need to be removed through a refining process. Before refining, however, the impure gold needs to be converted into a form that is beneficial to the refining process. This is where producing flakes or powders becomes critical.

The process of turning gold alloy into flakes or powder is a critical step in the refining process. It involves using specialized machines to transform solid gold alloy into the desired form. These flakes or powders have a larger surface area, which makes it easier for refining chemicals to interact with impurities and effectively remove them.

One of the main advantages of using a metal flake making machine is the ability to produce consistent and uniform flakes or powders. This uniformity is critical to ensuring that the refining process proceeds efficiently and effectively. The machine is capable of consistently producing gold alloys in the desired shape, which is crucial to obtaining high-quality refined gold.

In addition, the production of flakes or powders also facilitates efficient mixing of gold alloys with refining chemicals. The larger surface area of the flakes allows for better interaction between gold and chemicals, ensuring efficient targeting and removal of impurities during the refining process.

In addition to facilitating the refining process, the production of flakes or powders also facilitates the precise measurement of gold alloys. The uniformity of the flakes ensures that the exact amount of gold is used in the refining process, resulting in precise and accurate results.

In addition, the use of metal flake making machines also contributes to the overall safety of the refining process. By producing flakes or powders, the risk of exposure to hazardous chemicals is minimized because the larger surface area allows for better containment and control during the refining process.

It is important to note that the quality of the flakes or powder produced is critical to the success of the refining process. Therefore, it is crucial to choose a reliable, high-quality sheet metal making machine. The machine should be able to produce consistent, uniform and high-quality flakes or powder to ensure the effectiveness of the refining process.

In summary, producing flakes or powders from gold alloys is a critical step in the refining process. The use of metal flake making machines plays a key role in achieving this important step, helping to increase the efficiency, accuracy and safety of the refining process. By producing uniform, high-quality flakes or powder, the machine helps effectively remove impurities and produce the highest quality refined gold.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115