Metal Granulation Machine: Efficient Technology for High-Quality Metal Recycling

Product advantages

The Metal Granulation Machine is a cutting-edge technology designed for efficient metal recycling, offering high-quality results with minimal waste. Its advanced features allow for precise granulation of various metals, ensuring optimal output for recycling processes. With its durable construction and user-friendly interface, this machine is the ideal solution for businesses looking to enhance their metal recycling capabilities.

Company profile

With a commitment to innovation and sustainability, our company specializes in providing efficient technology for high-quality metal recycling. Our Metal Granulation Machine is designed to streamline the recycling process, allowing for effective and cost-efficient metal recovery. Our team of experts is dedicated to delivering cutting-edge solutions that not only elevate operational efficiency but also contribute to a greener future. By investing in our technology, customers can trust that they are working with a company that values quality, reliability, and environmental responsibility. Experience the difference with our Metal Granulation Machine and join us in revolutionizing the metal recycling industry.

Why choose us

Company Profile:

With a strong commitment to sustainability and innovation, our company specializes in developing cutting-edge technology for metal recycling. Our Metal Granulation Machine is a prime example of our dedication to efficiency and high-quality results. As experts in the field, we understand the importance of maximizing the value of metal scrap while minimizing waste. Our machine combines state-of-the-art technology with user-friendly design, delivering exceptional performance and reliability. Trust us to provide you with the tools you need to succeed in metal recycling, and join us in our mission to create a more sustainable future.

While Shenzhen Hasung Precious Metals Equipment Co., Ltd consciously carrying out personnel training and technological innovation, it also continuously strengthens external communication and exchanges to improve its own competitiveness. Hasung metal casting machinery metal grain making metal granulation machine attaches great importance to technological innovation in the research and development process. Shenzhen Hasung Precious Metals Equipment Co., Ltd will always stick to the business principle of 'quality first, customers foremost' and strive towards building an even more competitive and capable company aiming for an even better future.

Technical Specification:

| Model No. | HS-GS8 | HS-GS15 | HS-GS20 | HS-GS30 | HS-GS50 |

| Voltage | 380V, 50/60Hz, 3P | ||||

| Power | 15KW | 25KW | 30KW | 30KW | 30KW/40KW |

| Max Temp | 1500°C | ||||

| Temperature detector | Thermocouple | ||||

| Temp Accuracy | ±1°C | ||||

| Melting Time | 3-5 min. | 3-5 min. | 3-5 min. | 5-8 min. | 8-12 min. |

| Capacity (Gold) | 8kg | 15kg | 20kg | 30kg | 50kg |

| Application | Gold, K gold, silver, copper and other alloys | ||||

| Cooling method | Water chiller(sold separately) or Running water | ||||

| Air supply | Compressor air | ||||

| Inert gas | Argon/Nitrogen | ||||

| Dimensions | 1100x1020x1345mm | 1200x1150x1500m | |||

| Weight | Approx. 180kg | Approx. 250kg | |||

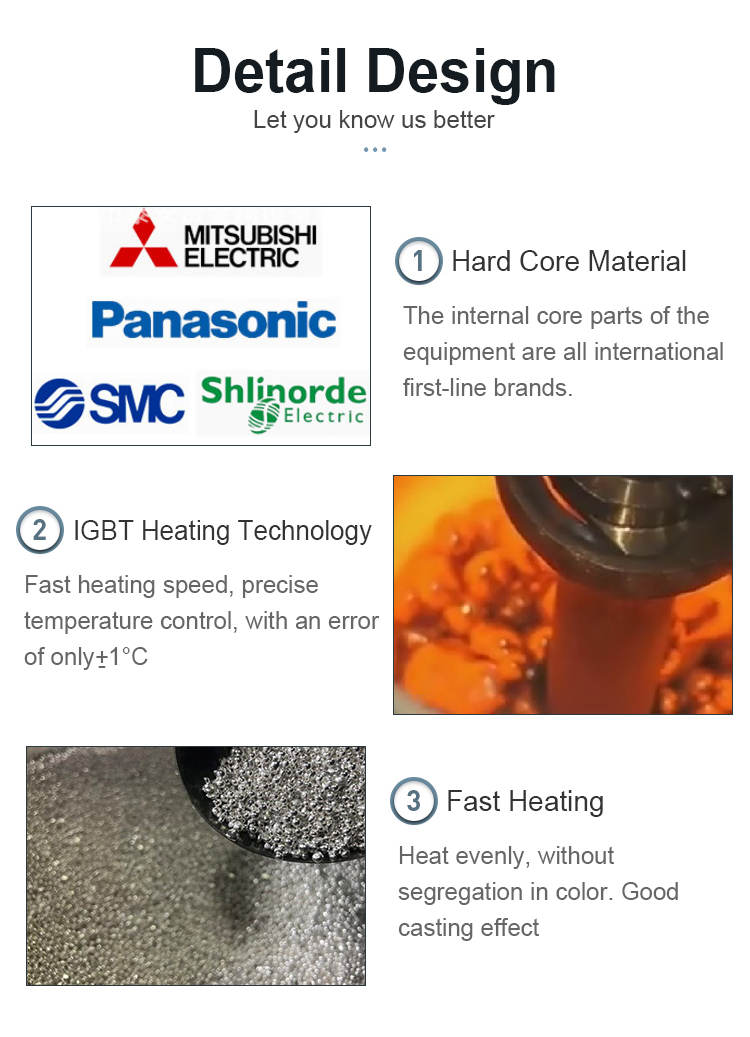

With temperature control, accuracy up to ±1°C.

Use imported Mitsubishi controller.

Silver Granulator with temperature control(Gold Silver Grains Casting Machine, Silver Granulating Machine).

This machine adopts Germany IGBT advanced heating technology, the casting effect is very good, the system is stable and safe, molten gold capacity is optional, and the granulated metal specification is optional. The granulation speed is fast and no noise. Perfect advanced testing and protection functions make the whole machine safe and durable. The machine has a split design and the body has more free space.

Water chiller for cooling.

Title: The Ultimate Guide to Metal Granulators: How They Work and Their Benefits

Are you in the metal recycling industry and looking for an efficient way to dispose of scrap metal? Metal granulator is your best choice. These powerful machines are designed to break down metal scrap into small, uniform pieces, making them easier to handle and transport. In this comprehensive guide, we’ll explore how metal pelletizers work, their benefits, and why they are a valuable asset to metal recycling businesses.

How does a metal granulator work?

Metal granulators, also known as metal granulators, cut and shred metal scrap into smaller pieces by using high-speed rotating blades. The scrap metal is fed into the machine where it is subjected to strong force and pressure, thereby undergoing the granulation process. The end product is uniformly sized and manageable metal pellets that can be used for further processing or recycling.

What are the benefits of using a metal granulator?

1. Improve efficiency: Metal granulators can process large amounts of metal scrap in a relatively short period of time, thereby increasing the productivity and efficiency of metal recycling operations.

2. Cost-effective: By breaking down metal scrap into smaller, uniform pieces, metal granulators make it easier to transport and store materials, ultimately reducing handling and transportation costs.

3. Environmental Impact: Metal granulators play a vital role in sustainable metal recycling practices. By processing scrap metal into pellets, the material can be more easily melted and reused, reducing the need for new metal production and minimizing environmental impact.

4. Versatility: The metal granulator can handle a variety of metal materials, including copper, aluminum, steel, etc., making it a versatile solution for a variety of metal recycling needs.

5. Quality Output: The granular metal produced by these machines is of high quality and uniform in size, making it ideal for further processing or direct use in the manufacturing process.

In summary, metal pelletizers are valuable assets for metal recycling businesses, improving efficiency, cost-effectiveness, and environmental benefits. By understanding how these machines work and their many benefits, businesses can make informed decisions about incorporating them into their metal recycling operations. Whether you are processing copper, aluminum or scrap steel, a metal pelletizer can help streamline your operation and contribute to a more sustainable approach to metal recycling.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115