Metal Powder Atomizer - Customizable Ultrasonic Equipment

Product features

The metal powder atomization equipment is designed to produce high-quality spherical powder in small batches at an affordable price. The machine features a crucible-based induction heating system for precise control of melting temperature and alloy composition, ensuring excellent powder fluidity and density. With the ability to create custom alloy compositions and a strong stirring effect, this equipment is ideal for a wide range of applications in precious metals casting and refining.

Company profile

Company Profile:

Founded in 2005, our company specializes in producing high-quality metal powder atomizers and customizable ultrasonic equipment. With a strong focus on innovation and customization, we aim to provide our customers with the most advanced and reliable products in the market. Our team of experts works tirelessly to ensure that each product meets the highest standards of quality and performance. We pride ourselves on our commitment to customer satisfaction and strive to exceed expectations with every interaction. Trust us to deliver cutting-edge technology and superior customer service for all your metal powder atomization and ultrasonic equipment needs.

Enterprise core strength

Company Profile:

As a leading provider of customizable ultrasonic equipment, our company specializes in designing and manufacturing high-quality metal powder atomizers. With a strong commitment to innovation and precision engineering, we create cutting-edge solutions to meet the unique needs of our clients in various industries. Our team of experts combines expertise with state-of-the-art technology to deliver top-of-the-line products that are reliable, efficient, and cost-effective. From concept to completion, we work closely with our customers to ensure a seamless and tailored experience. Trust us to exceed your expectations and provide you with the perfect atomizer solution for your specific requirements.

Product Information

The Metal Powder Water Atomizer Unit enables almost anybody to produce small batches of high-quality, spherical powder for the same target application as gas atomized powder at an affordable price and without having a complex infrastructure.

The MGA series is available in different batch sizes.

The melting and alloying of the material in the crucible takes place with an indirect induction system (e.g. graphite crucible) or a direct induction system for high temperatures (ceramic crucible). With a diversity of optional features, the machine could be equipped according to the specific requirements.

Feedstock can be in more or less any shape – not just pre-alloyed wire or bar, as long as it can be input into crucible.

No need for complex and expensive wire production as feedstock material for atomizing, which is time-consuming and requires additional infrastructure like continuous casting machines, a drawing bench etc.

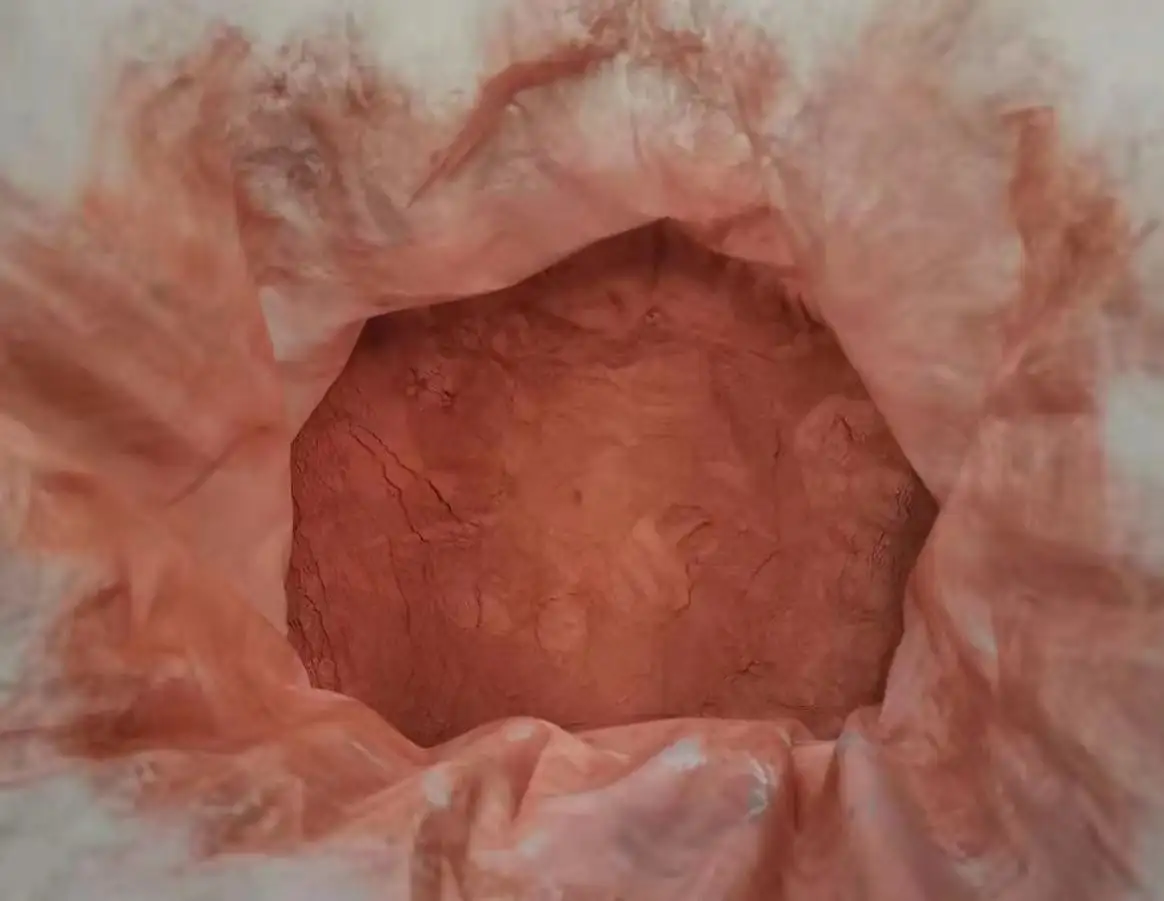

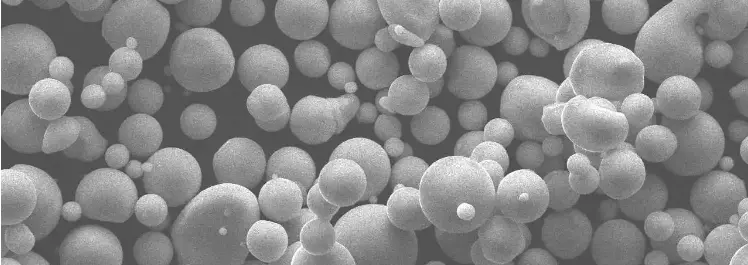

Extremely spherical powder

without any satellites for the highest powder fluidity and bulk density. Could be basically used as well for non-metallic materials (certain fluidity required).

Advantages of crucible-based ultrasonic atomizing principle

Prevention of material loss and inaccuracy of alloy chemistry

due to precise control of the melting temperature via a crucible based induction heating system, while evaporation of alloy ingredients like Zn, Cr etc. is a common issue during plasma-assisted atomization.

Possibility to create own alloy composition inside of the Atomizer's crucible-based melting system.

Alloying with a good stirring/mixing effect due to strong medium- frequency induction generator with simultaneous high heating efficiency. Melting under vacuum or inert gas atmosphere and atomizing under inert gas atmosphere.

Metal powder atomizer includes:

1.Smelting Chamber 1 set;

2. Atomization system 1 set;

3. Control System 1 set;

4. Operation Platform 1 set;

5. High pressure water pump 1 set;

6. Water Storage System 1 set;

7. Separation System 1 set;

8. 1 set of Crucible.

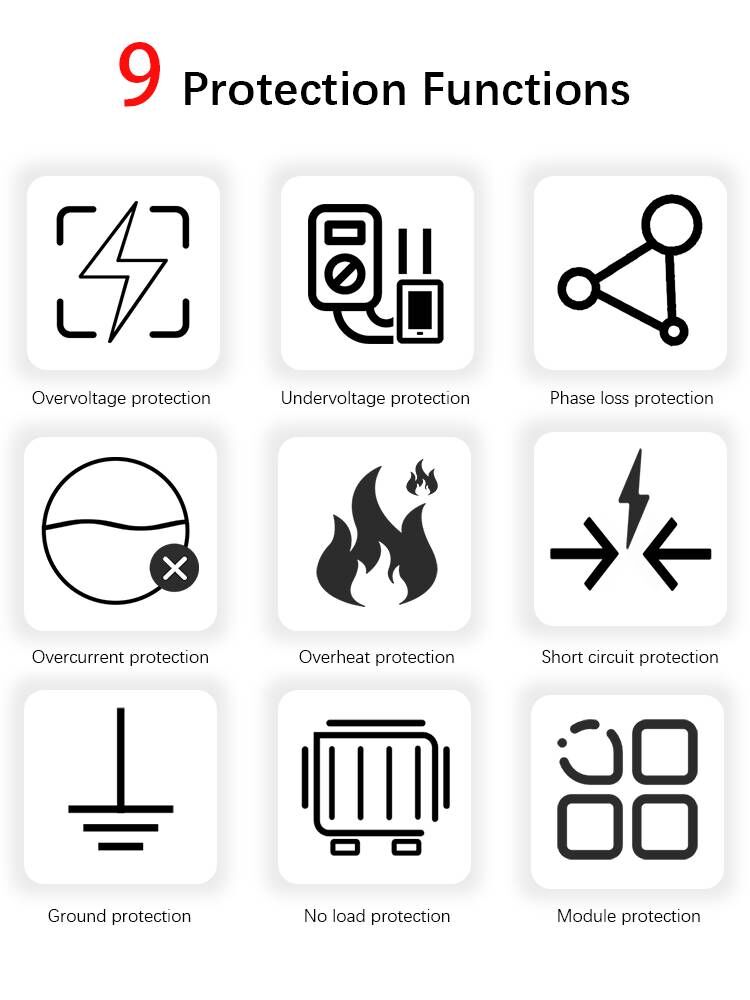

Company Advantages

We provide a one-stop service for precious metals casting solutions.

Our factory has passed the ISO 9001 international quality certification

We select raw material suppliers carrying the certificates that 100% guarantee the materials and apply world famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc.

It is extensively used in precious metals refining, precious metals smelting, precious metals bars, beads, powders trading, gold jewellery, etc.

Technical data:

| Model No. | HS-MGA5 | HS-MGA10 | HS-MGA30 | HS-MGA50 | HS-MGA100 |

| Voltage | 380V 3 Phases, 50/60Hz | ||||

| Power Supply | 15KW | 30KW | 30KW/50KW | 60KW | |

| Capacity (Au) | 5kg | 10kg | 30kg | 50kg | 100kg |

| Max Temp. | 1600°C/2200°C | ||||

| Melting time | 3-5 min. | 5-8 min. | 5-8 min. | 6-10 min. | 15-20 min. |

| Particle grains size (mesh) | 200#-300#-400#-500# | ||||

| Temp Accuracy | ±1°C | ||||

| Vacuum Pump | High quality high level vacuum degree vacuum pump | ||||

| Ultrasonic system | High quality Ultrasonic system control system | ||||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||||

| Control System | Mitsubishi PLC+Human-machine interface intelligent control system | ||||

| Inert gas | Nitrogen/Argon | ||||

| Cooling type | Water chiller (Sold separately) | ||||

| Dimensions | approx. 3575*3500*4160mm | ||||

| Weight | approx. 2150kg | approx. 3000kg | |||

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115