Metal Powder Water Atomizing Machine - Small Scale Flexibility

Product advantages

The Metal Powder Water Atomizing Machine offers small scale flexibility, allowing for efficient production of metal powders in various quantities to meet diverse needs. Its advanced atomizing technology ensures high-quality powder production with consistent particle size distribution. With user-friendly controls and reliable performance, this machine is a valuable tool for companies looking to optimize their metal powder production processes.

Company profile

With a strong commitment to innovation and quality, our company specializes in designing and manufacturing metal powder water atomizing machines. Our small-scale flexibility allows us to cater to a wide range of needs, making us the go-to choice for customers looking for customized solutions. We pride ourselves on our attention to detail and dedication to customer satisfaction, ensuring that every machine we produce meets the highest standards of performance and reliability. With years of experience in the industry, we continue to push the boundaries of technology to deliver cutting-edge products that exceed expectations. Trust us to provide you with the best metal powder water atomizing machine for your needs.

Why choose us

Our company specializes in providing cutting-edge metal powder water atomizing machines tailored for small-scale flexibility. With years of expertise in the industry, we have successfully developed a range of innovative and high-performance machines that meet the demands of modern manufacturing processes. Our commitment to quality, precision, and efficiency sets us apart as a trusted partner for businesses looking to enhance their production capabilities. We take pride in our ability to deliver reliable and cost-effective solutions that drive growth and success for our customers. Trust us to elevate your metal powder production with our state-of-the-art technologies.

The Metal Powder Water Atomizer Unit enables almost anybody to produce small batches of high quality, spherical powder for the same target application as gas atomized powder at an affordable price and without having a complex infrastructure.

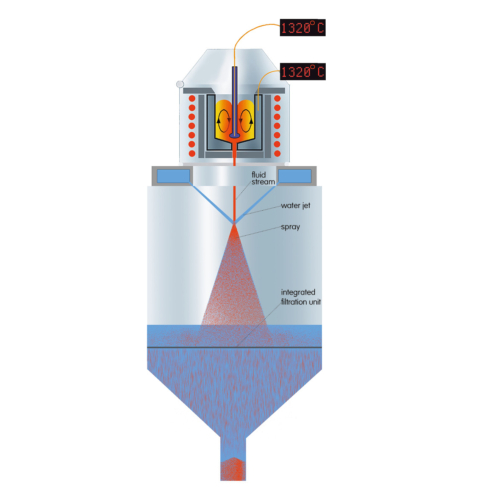

Overview of water atomizer

The MGA series is available in different batch sizes.

The melting and alloying of the material in the crucible takes place with an indirect induction system (e.g. graphite crucible) or a direct induction system for high temperatures (ceramic crucible). With a diversity of optional features, the machine could be equipped according to the specific requirements.

Feedstock can be in more or less any shape – not just pre-alloyed wire or bar, as long as it can be input into crucible.

No need for complex and expensive wire production as feedstock material for atomizing, which is time-consuming and requires additional infrastructure like continuous casting machines, a drawing bench etc.

Extremely spherical powder

without any satellites for the highest powder fluidity and bulk density. Could be basically used as well for non-metallic materials (certain fluidity required).

Advantages of crucible-based ultrasonic atomizing principle

Prevention of material loss and inaccuracy of alloy chemistry

due to precise control of the melting temperature via a crucible based induction heating system, while evaporation of alloy ingredients like Zn, Cr etc. is a common issue during plasma-assisted atomization.

Possibility to create own alloy composition inside of the Atomizer's crucible-based melting system.

Alloying with a good stirring/mixing effect due to strong medium- frequency induction generator with simultaneous high heating efficiency. Melting under vacuum or inert gas atmosphere and atomizing under inert gas atmosphere.

Metal powder atomizer includes:

1.Smelting Chamber 1 set;

2. Atomization system 1 set;

3. Control System 1 set;

4. Operation Platform 1 set;

5. High pressure water pump 1 set;

6. Water Storage System 1 set;

7. Separation System 1 set;

8. 1 set of Crucible.

Model No. | HS-GMI10 | HS-GMI50 |

Voltage | 380V 3 Phases, 50/60Hz | |

Total Power Supply | 100KW | 120KW |

Max Temp | 1450°C | |

Melting Time | 5-10 Min. | 20-25 Min. |

Powder sizes | 75-270 microns (Adjust.) | |

Temp Accuracy | ±1°C | |

Capacity | 10kg (Gold) | 30kg (Gold) |

| Water pressure | 0.2-0.4Mpa | |

| Water temp. | 18-22°C | |

| Atomizing disk | Adopt imported Germany original components and technology | |

Vacuum Pump | High level vacuum degree pump | |

Application | Gold, silver, copper, alloys | |

Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |

| High pressure pump | Touch penal control system | |

Induction Generator Control System | Mitsubishi PLC+Human-machine interface intelligent control system | |

Shielding Gas | Nitrogen/Argon | |

Cooling type | Water chiller (Sold separately) | |

Dimensions | 3400*3200*3880mm | |

Weight | approx. 2800kg | |

Description

Intelligent metal atomization powder making equipment is designed and manufactured by Shenzhen Hasung Precious Metals Equipment Co., Ltd, specially designed to produce small-scale metal powder batches flexibly and economically. Traditional large-scale production plants cannot provide this economic advantage. Alloys that are frequently changed during production require high purity to avoid cross contamination. Especially in aviation, aerospace or precious metal powder applications, small amounts of various powders are often required, and there are usually new alloy powders that are not available on the market. Especially fast-developing applications such as SLM and MIM require more and more special metal powders.

Samples:

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and casting equipment, especially for high tech vacuum and high vacuum casting machines. Welcome to visit our factory in Shenzhen, China.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality. Q: Where are your factory located? A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115