Platinum Shot Maker Granulator - Precision Performance

Product advantages

The Platinum Shot Maker Granulator is meticulously crafted for precision performance, embodying the brand's commitment to excellence in materials and design. Its cutting-edge technology ensures consistent and reliable granulation, offering superior quality and efficiency in production. With features such as adjustable speed control and an intuitive interface, this innovative machine delivers unmatched accuracy and productivity for your manufacturing needs.

We serve

At Precision Performance, we serve our customers with excellence through our Platinum Shot Maker Granulator. Our advanced technology and precise engineering ensure optimal performance and efficiency in creating high-quality shot products. With a commitment to reliability and innovation, we provide a seamless user experience, allowing you to effortlessly produce consistent and uniform shots every time. Our dedicated team is here to serve you every step of the way, offering support and expertise to help you maximize the potential of your granulator. Experience the difference with Precision Performance and elevate your production capabilities today.

Enterprise core strength

At Platinum Shot Maker, we are committed to serving our customers with precision performance in mind. Our Granulator is designed to provide top-of-the-line efficiency and accuracy for all your production needs. With user-friendly controls and high-quality materials, our product ensures a seamless operation every time. We serve by offering reliability, durability, and high-performance capabilities to help you achieve your goals with ease. Trust in Platinum Shot Maker to deliver exceptional results and elevate your production process. Experience the difference with our Granulator and let us serve you with excellence in every detail.

Product Introduction

The platinum granulating system (also called platinum "shotmakers") is developed especially for granulating bullions, sheet metal or casting residues grains for platinum.

The granulating tank is designed as longer than usual granulator tank with platform. The system includes induction generator, melting chamber with granulating tank, platform.

Features:

1. With temperature control, accuracy up to ±1°C.

2. With inert gas protection, Saving energy, fast melting.

3. Apply Germany technology, imported parts. With Mitsubishi PLC touch panel, Panasonic electric, SMC eletric, Germany Omron, Schneider, etc. to ensure first class quality.

Technical data:

| Model No. | HS-PGM2 | HS-PGM10 | HS-PGM20 |

| Voltage | 380V, 50Hz, 3 phase, | ||

| Power | 0-15KW | 0-30KW | 0-50KW |

| Capacity (Pt) | 2kg | 10kg | 20kg |

| Max. Temperture | 2100°C | ||

| Temp Accuracy | ±1°C | ||

| Melting time | 3-6 min. | 5-10 min. | 8-15 min. |

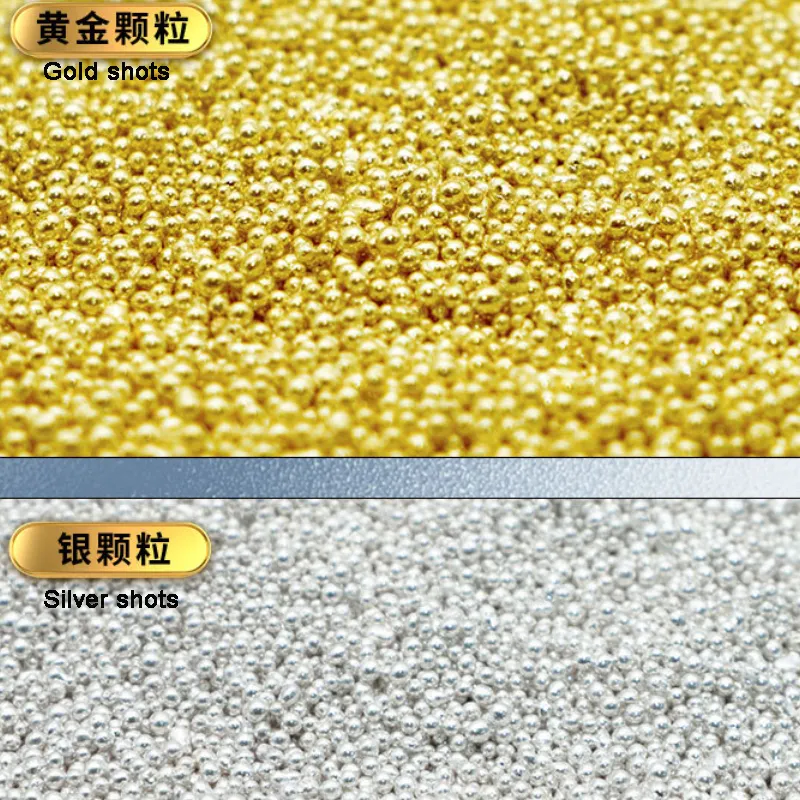

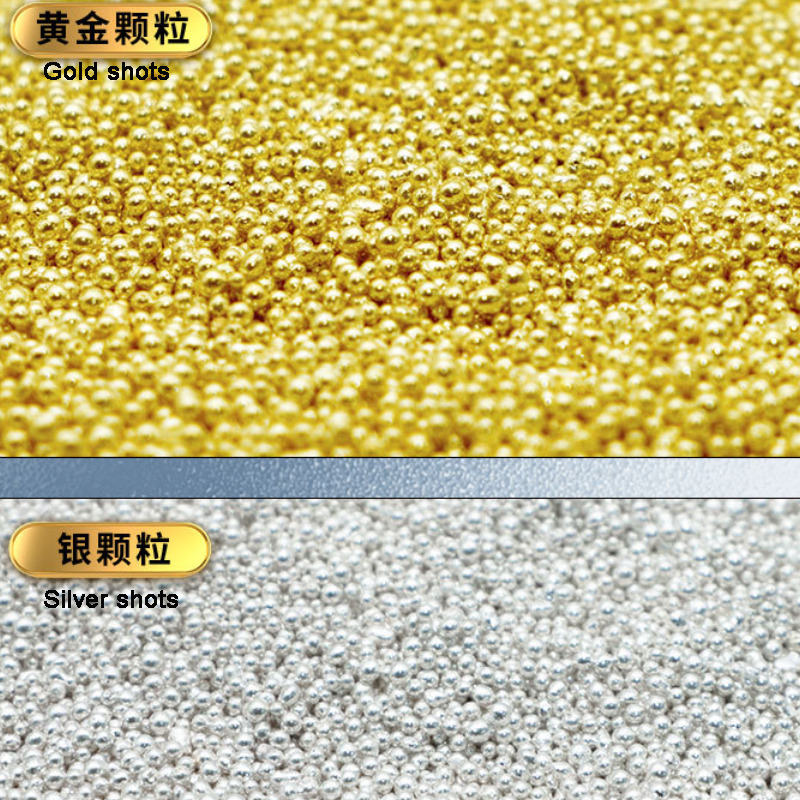

| Granule size | 2-5mm | ||

| Application | Platinum, Palladium | ||

| Inert gas | Argon/Nitrogen | ||

| Dimensions | 3400*3200*4200mm | ||

| Weight | approx. 1800kg | ||

Company Advantages

Frequently Asked Questions about copper melting machine

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115