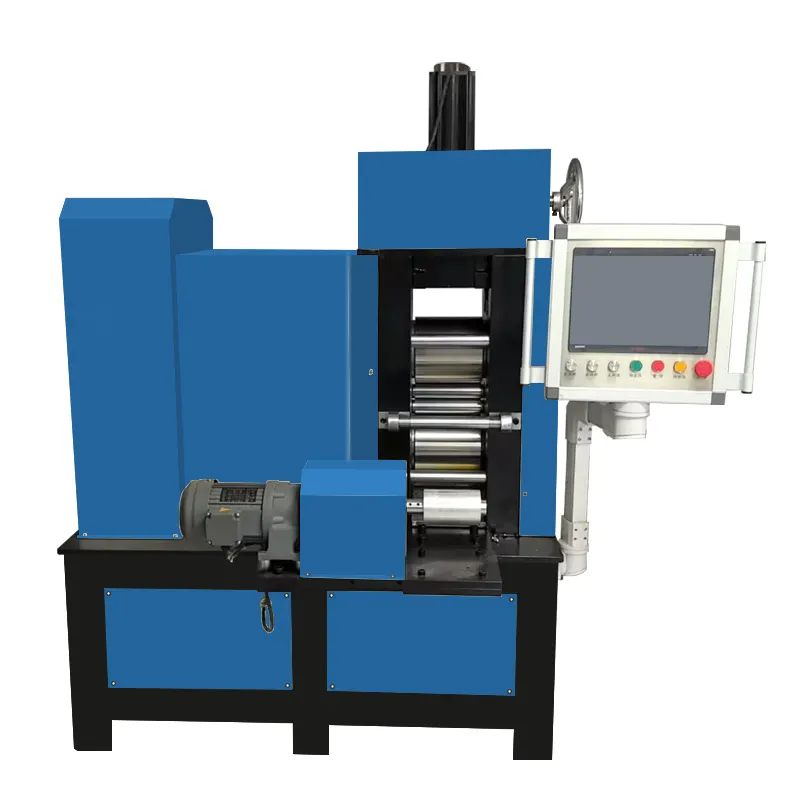

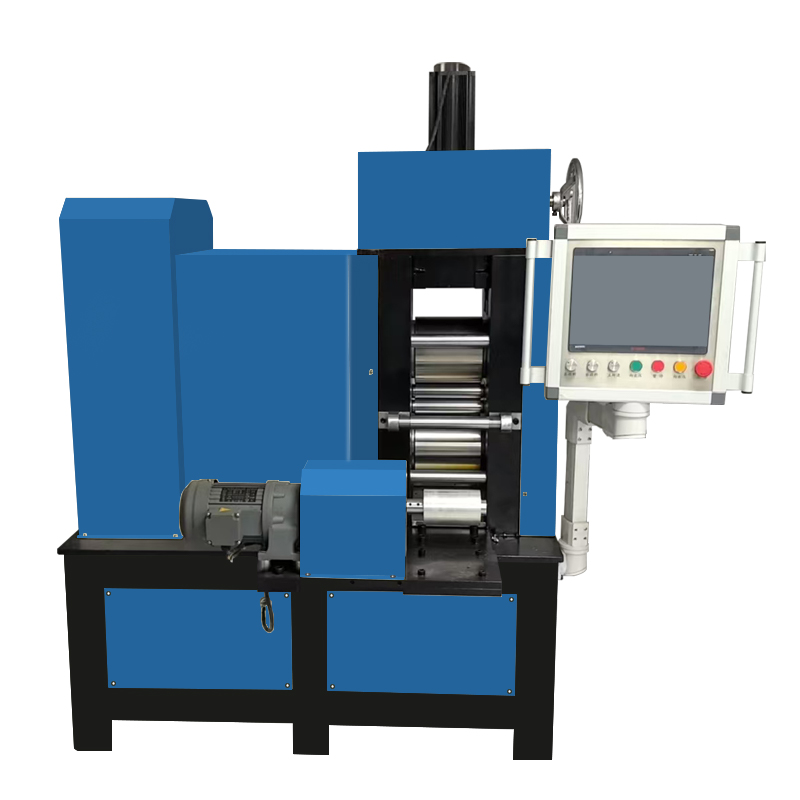

Precision Tungsten Carbide Silver Wire Strip Rolling Mill

Product features

The Precision Tungsten Carbide Silver Wire Strip Rolling Mill, also known as a silver wire making machine, offers high precision with 5.5HP Tungsten Carbide Mirror Surface Rolling capabilities. This machine is designed for making gold, silver, and copper thin sheets, with a minimum thickness of 0.02-0.04mm for gold and 0.04mm for copper. It features a clutch with synchronous magnetic powder, DC53 or HSS roller material with a hardness of 63-67HRC, and dimensions of 1100*1050*1350mm, weighing approximately 400kg.

Team strength

At the heart of the Precision Tungsten Carbide Silver Wire Strip Rolling Mill lies a dedicated team of experts who work seamlessly together to ensure the highest level of precision and quality in every product. Our team's strength lies in their unparalleled knowledge of tungsten carbide materials and their diligent attention to detail throughout the manufacturing process. With a shared commitment to excellence and a passion for innovation, our team consistently delivers superior products that meet the needs and exceed the expectations of our customers. Trust in the strength of our team to provide you with the best tungsten carbide wire strip rolling mill on the market.

Why choose us

At Precision Tungsten Carbide, our team strength lies in our expertise and commitment to delivering high-quality products. Our Silver Wire Strip Rolling Mill is a testament to our dedication to precision engineering and innovation. Our team of skilled engineers and technicians work tirelessly to ensure that each product meets the highest standards of quality and performance. With a focus on teamwork and collaboration, we strive to constantly improve and exceed customer expectations. Trust in our team's strength to provide you with the best-in-class tungsten carbide products for all your rolling mill needs.

Product Introduction

Introduction

Hasung High precision 5.5HP Tungsten Carbide Mirror Surface Rolling Mill, used for making gold silver copper thin sheet, for gold, could be minimum 0.02-0.04mm, for copper, could be minimum 0.04mm.

With Clutch with synchronous magnetic powder.

| MODEL NO. | HS-F10HPC |

| Brand Name | HASUNG |

| Voltage | 380V 50Hz, 3 Phase |

| Main Motor power | 7.5KW |

| Motor for winding and unwinding power | 100W * 2 |

| Roller size | diameter 200 × width 200mm, diameter 50 × width 200mm |

| Roller material | DC53 or HSS |

| Roller hardness | 63-67HRC |

| Dimensions | 1100* 1050*1350mm |

| Weight | approx. 400kg |

| Tension Controller | Press down accuracy +/- 0.001mm |

| Mini. output thickness | 0.004-0.005mm |

Advantage

The input thickness of the tablet is 5mm, minimum rolling sheet size for gold sheet is 0.004-0.005mm, the frame is electro-statically dusted, the body is plated with decorative hard chrome, and the stainless steel cover is beautiful and practical without rust. with winding and unwinding reversible coilers. With magnetic powder clutch.

After Warranty Service

Video technical support, Online support, Spare parts, Field maintenance and repair service

Company Advantages

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115