Silver Vacuum Granulating Machine - High Efficiency, Quality Assurance

Product advantages

The Silver Vacuum Granulating Machine offers high efficiency and quality assurance in creating granules for various industrial applications. Its advanced technology allows for precise granule formation, ensuring a consistent and uniform product every time. With its easy-to-use design and durable construction, this machine provides reliable performance and peace of mind for businesses seeking top-quality granulating solutions.

Company profile

Our company specializes in providing high-quality industrial machinery such as the Silver Vacuum Granulating Machine. With a focus on efficiency and quality assurance, we pride ourselves on delivering top-of-the-line products to meet the needs of our customers. Our team of experts ensures that each machine is built to last and operates at peak performance, making it a reliable choice for any manufacturing operation. Trust in our company for advanced technology, exceptional craftsmanship, and unmatched customer service. Experience the difference with our Silver Vacuum Granulating Machine and see why we are the preferred choice for businesses worldwide.

Enterprise core strength

With a commitment to high efficiency and quality assurance, our company specializes in producing top-of-the-line silver vacuum granulating machines. Our advanced technology and innovative design ensure optimal performance and precision in the granulation process. From small-scale operations to large-scale industrial applications, our machines are built to deliver consistent results and meet the highest standards. With a focus on customer satisfaction and reliability, we strive to provide the best products and service in the industry. Trust in our company for all your granulating needs and experience the difference in quality and efficiency.

Description

Using Germany IGBT induction heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

2. The closed type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Using a closed + vacuum/inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved.

4. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

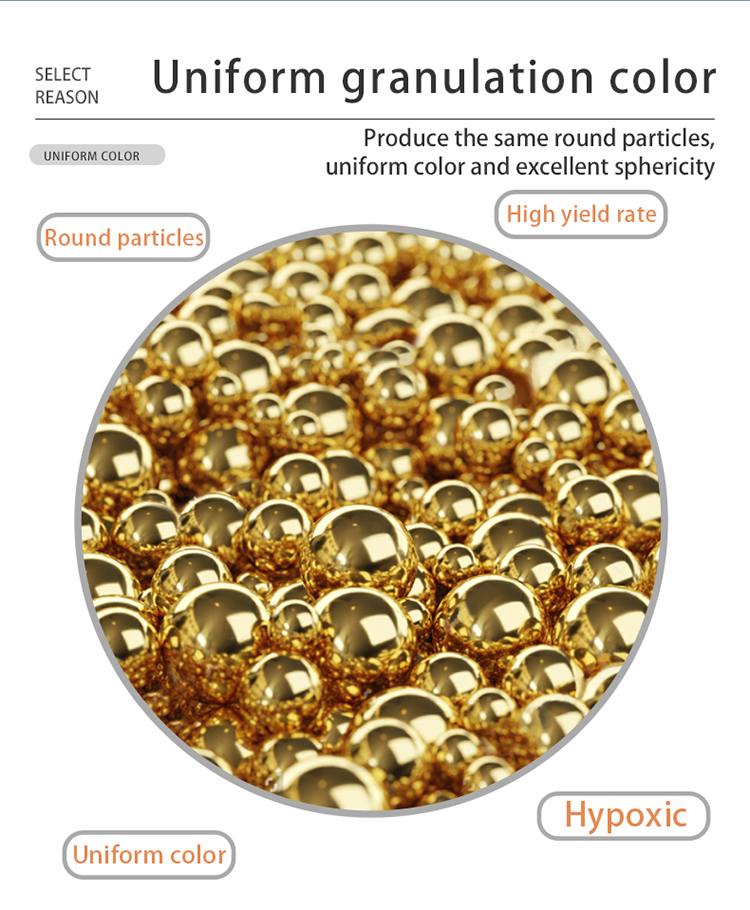

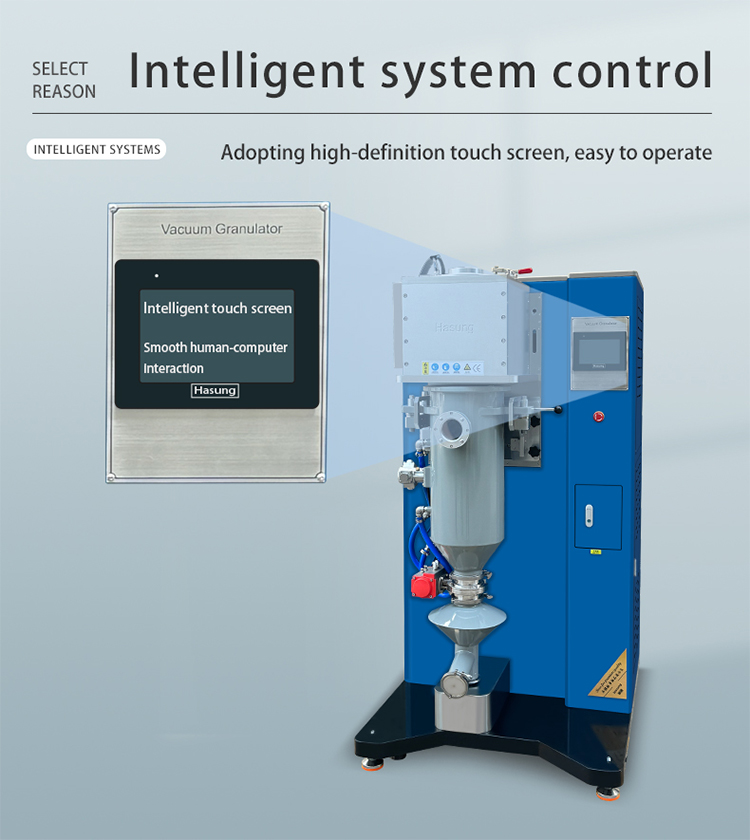

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color. 6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. Using PID temperature control system, the temperature is more accurate (±1°C). The HS-GR vacuum system casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of gold, silver, copper.

9. This equipment uses Japan SMC pneumatic, IDEC, Shimaden, Germany Omron, Siemens, and other well-known brand components at home and abroad.

10. Melting, electromagnetic stirring, and refrigeration in a closed + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

Technical data

Model No. | HS-VGR20 | HS-VGR30 | HS-VGR50 | HS-VGR100 |

Voltage | 220V, 50/60Hz | 220V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

Power Supply | 0-30KW | 0-30KW | 0-30KW | 0-50KW |

Max Temp | 1500°C | |||

Melting Time | 8-10 min. | 8-15 min. | 10-15 min. | 20-25 min. |

Shielding Gas | Argon / Nitrogen | |||

Temp Accuracy | ±1°C | |||

Capacity (Gold) | 20kg | 30kg | 50kg | 100kg |

Application | Gold, K gold, silver, copper and other alloys | |||

Vacuum | High level degree vacuum pump German Vacuum Pump, Vacuum degree-100KPA | |||

Operation method | Auto mode and manual mode both | |||

Control system | 10" Taiwan Weinview Touch screen + Siemens PLC intelligent control system | |||

Cooling type | Water chiller(sold separately) or Running water | |||

Dimensions | 1150*970*1860mm 1250*970*1950mm | |||

Weight | approx. 450kg approx. 550kg | |||

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115