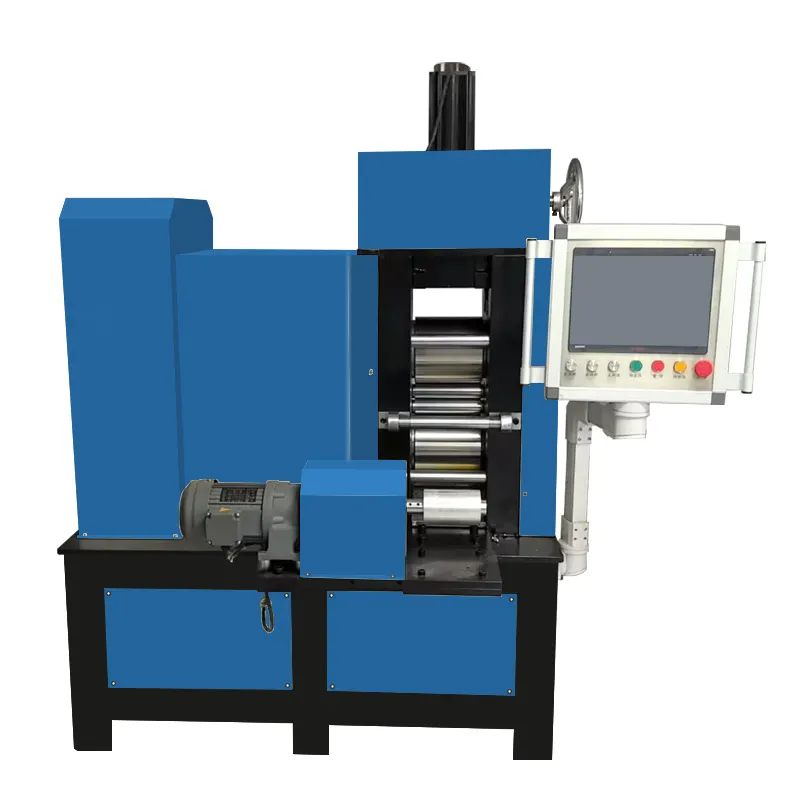

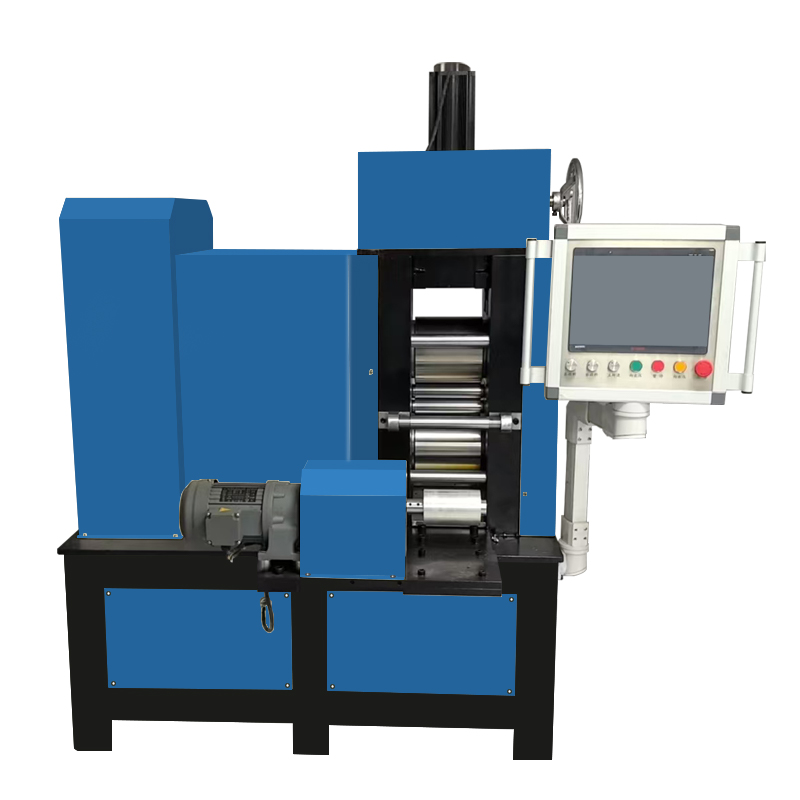

Tungsten Carbide Mirror Surface Rolling Mill for Jewelry

Product features

The electric rolling mill for jewelry features a high precision 5.5HP Tungsten Carbide Mirror Surface Rolling Mill, ideal for creating gold, silver, and copper thin sheets with a minimum thickness of 0.02-0.04mm for gold and 0.04mm for copper. With clutch and synchronous magnetic powder, this model ensures accurate and smooth operation. The machine boasts a sturdy construction with rollers made of DC53 or HSS materials, guaranteeing a hardness of 63-67HRC for efficient and precise rolling of metal sheets.

Team strength

At Tungsten Tech, our team's strength lies in our unwavering dedication to craftsmanship and innovation. Our skilled engineers and technicians work hand in hand to design and produce top-quality tools such as the Tungsten Carbide Mirror Surface Rolling Mill for Jewelry. With a deep understanding of the jewelry industry's needs, our team ensures that every mill is crafted with precision and durability in mind. Our commitment to excellence and continuous improvement sets us apart, allowing us to provide our customers with reliable and efficient tools that exceed their expectations. Trust in our team's expertise to elevate your jewelry-making process to new heights.

Enterprise core strength

Our Tungsten Carbide Mirror Surface Rolling Mill for Jewelry is a testament to our team's strength in innovation and craftsmanship. With precision engineering and cutting-edge technology, our team of experts has developed a high-quality rolling mill that ensures flawless and uniform results every time. The durability and longevity of our product are a reflection of our team's dedication to excellence. Trust in our team's experience and expertise to elevate your jewelry-making processes to new heights. Invest in our Tungsten Carbide Rolling Mill and experience the strength of our team in every detail.

Product Introduction

Introduction

Hasung High precision 5.5HP Tungsten Carbide Mirror Surface Rolling Mill, used for making gold silver copper thin sheet, for gold, could be minimum 0.02-0.04mm, for copper, could be minimum 0.04mm.

With Clutch with synchronous magnetic powder.

| MODEL NO. | HS-F10HPC |

| Brand Name | HASUNG |

| Voltage | 380V 50Hz, 3 Phase |

| Main Motor power | 7.5KW |

| Motor for winding and unwinding power | 100W * 2 |

| Roller size | diameter 200 × width 200mm, diameter 50 × width 200mm |

| Roller material | DC53 or HSS |

| Roller hardness | 63-67HRC |

| Dimensions | 1100* 1050*1350mm |

| Weight | approx. 400kg |

| Tension Controller | Press down accuracy +/- 0.001mm |

| Mini. output thickness | 0.004-0.005mm |

Advantage

The input thickness of the tablet is 5mm, minimum rolling sheet size for gold sheet is 0.004-0.005mm, the frame is electro-statically dusted, the body is plated with decorative hard chrome, and the stainless steel cover is beautiful and practical without rust. with winding and unwinding reversible coilers. With magnetic powder clutch.

After Warranty Service

Video technical support, Online support, Spare parts, Field maintenance and repair service

Company Advantages

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115