Vacuum Gold Bar Making Machine - High Performance & Quality

Product advantages

The Vacuum Gold Bar Making Machine is a high-performance machine known for its top-quality manufacturing process and materials. With innovative features like precision temperature control and automatic bar shaping, this machine ensures consistent and flawless production of gold bars. Its advanced technology and reliable performance make it the ideal choice for goldsmiths and manufacturers looking to create high-quality gold bars with ease.

Company profile

Company Profile: With a reputation for excellence in the industry, our company specializes in manufacturing high-quality vacuum gold bar making machines. Our dedication to precision engineering and advanced technology ensures that our products deliver optimal performance and durability. We take pride in our commitment to customer satisfaction, providing reliable equipment that meets the highest standards of quality. Our team of experts is dedicated to innovation and continuous improvement, ensuring that our machines remain at the forefront of the industry. Trust in our expertise and experience to provide you with a vacuum gold bar making machine that exceeds your expectations.

Enterprise core strength

At Vacuum Gold Bar Making Machine, we are dedicated to providing high performance and quality equipment for creating gold bars with precision and efficiency. With cutting-edge technology and superior craftsmanship, our machines are designed to meet the demands of the most discerning customers in the precious metals industry. Our commitment to innovation and customer satisfaction sets us apart from the competition, ensuring that our clients receive the best products available on the market. Trust Vacuum Gold Bar Making Machine for all your gold bar production needs and experience the difference in quality and performance firsthand.

Product Information

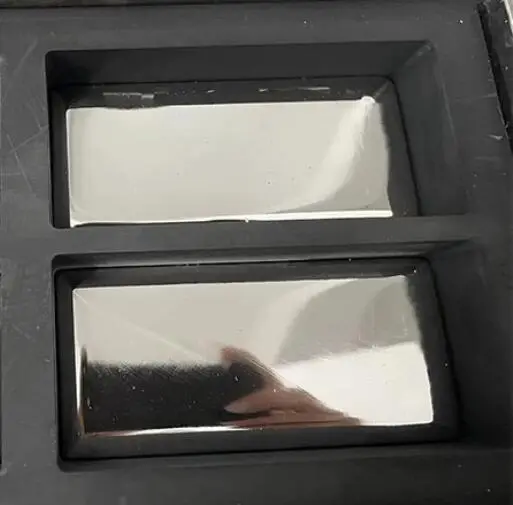

This silver casting machine & gold vacuum casting machine compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market. Customers got a real answer to know why our machines are the best. Energy saving, speedy melting, accurate temperature control, saving argon, super high degree vacuum tightness, super perfect gold bar results, etc. Customers who already used our machine domestic threw away the all other suppliers' machines.

Key Features:

1. This silver & gold vacuum casting machine using German Medium-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving, and high work efficiency.

2. Making high quality 99.99% gold bars or 99.9%, 99.999% silver bars perfectly.

3. Full automatic operation, vacuum with inert gas are all automatically filled. One key controls the entire casting process.

4. Melting in an inert gas environment, the oxidation loss of the carbon mold is almost negligible.

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. HS-GV1; HS-GV2; gold and silver ingot forming equipment/full-automatic production line is independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper and other alloys.

9. This equipment uses Siemens PLC program control system, SMC/Airtec pneumatic and Japan IDEC, Shimaden, and other domestic and foreign brand components.

10. Melting, electromagnetic stirring, and refrigeration in a closed/channel + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

Technical Specifications:

| Model No. | HS-GV2 |

| Voltage | 380V, 50/60Hz, 3 phases |

| Power | 20KW |

| Max Temp. | 1500°C |

| Overall Casting Time | 10-12 min. |

| Inert Gas | Argon / Nitrogen |

| Cover Controller | Full Automatic |

| Capacity (Gold) | 2kg (1pcs 2kg, 2pcs 1kg; 500g, 250g, 200g, 100g, 50g, 20g, 10g, 5g, 1g etc.) |

| Application | Gold, silver |

| Vacuum | High quality vacuum pump (optional) |

| Control system | 7" Siemens Touch Panel + Siemens PLC intelligent control system |

| Operation method | One key mode operation to finish the entire casting process |

| Cooling type | Water chiller(sold separately) |

| Heating method | Germany IGBT induction heating technology (self-developed) |

| Dimensions | 830x850x1010mm |

| Weight | approx. 220kg |

Advantages:

◆Unmatched Performance:

Faster melting and pouring cycles compared to competitors.

Consistent bar/ingot quality with minimal defects.

◆Superior Quality:

Durable construction with high-grade materials.

Long service life and low maintenance requirements.

◆Aesthetic Design:

Sleek, modern appearance with a focus on ergonomic design.

Compact footprint for space-efficient production.

◆Customization Flexibility:

Tailor the machine to your specific production needs.

Support for branding and custom packaging.

◆Energy Efficiency:

Reduces power consumption and operational costs.

How It Works:

1、Pre-Casting Preparation:

Precious metal (gold, silver, etc.) is placed in a graphite or ceramic mold within the vacuum chamber.

Chamber is sealed, and vacuum pump removes oxygen to prevent oxidation.

2、Melting & Pouring:

High-frequency induction heating melts the metal within 10-15 minutes (2KG model).

Vacuum pouring ensures no air bubbles or impurities.

3、Cooling & Demolding:

Built-in cooling system accelerates solidification.

Automated demolding ensures bar/ingot integrity.

Applications:

1.Gold Refining & Bullion Production:Standardized gold bar/ingot production for banks, mints, and bullion dealers.

2.Jewelry Manufacturing:Custom gold and silver bar/ingot casting for high-end jewelry brands.Production of investment-grade gold and silver bars.

3.Minting & Coin Production:Support for casting gold and silver blanks for coin production.

As one of the most popular products, Hasung silver casting machine gold bar making machine wins increasing popularity. At Shenzhen Hasung Precious Metals Equipment Co., Ltd,customer satisfaction and professional service as well as competitive prices are very important to us, a happy customer is what we strive to achieve. Shenzhen Hasung Precious Metals Equipment Co., Ltd will continue to gather more industry elites and improve our technology to upgrade ourselves. We hope to achieve the goal of realizing independent production without relying on others' technologies.

Company Advantages

Frequently Asked Questions about metal casting machine

Consistency: Eliminates human error for uniform bar weight/purity.

Cost-Efficient: Lowers labor costs and material waste.

Lifetime Service: Free troubleshooting (excluding consumables).

2-Year Warranty: Covers defects and performance.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115