Vacuum Gold Granulating System: High-Quality Equipment for Precious Metals

Product features

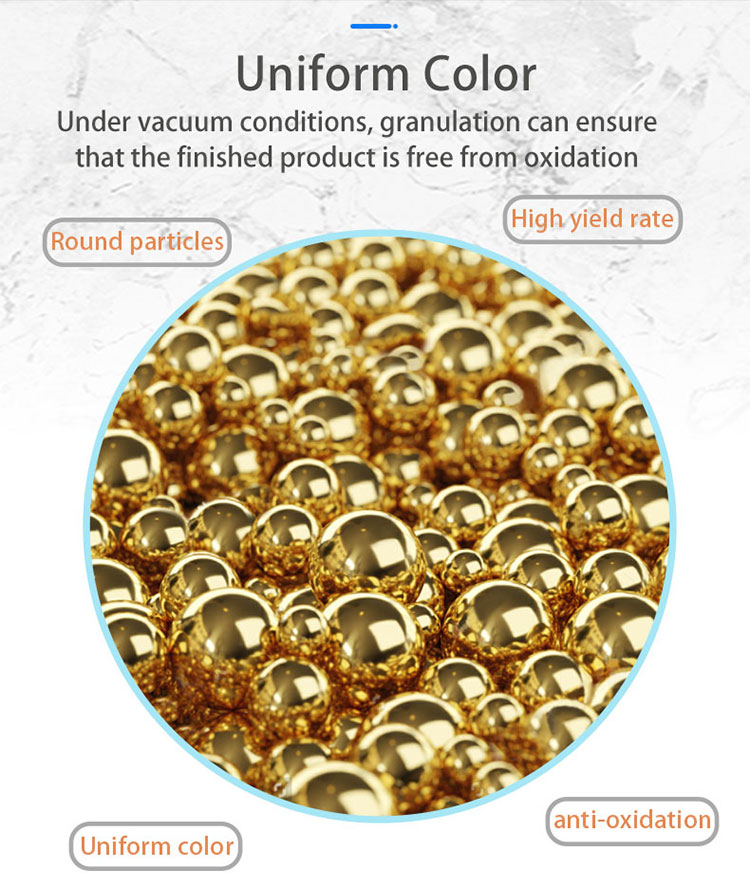

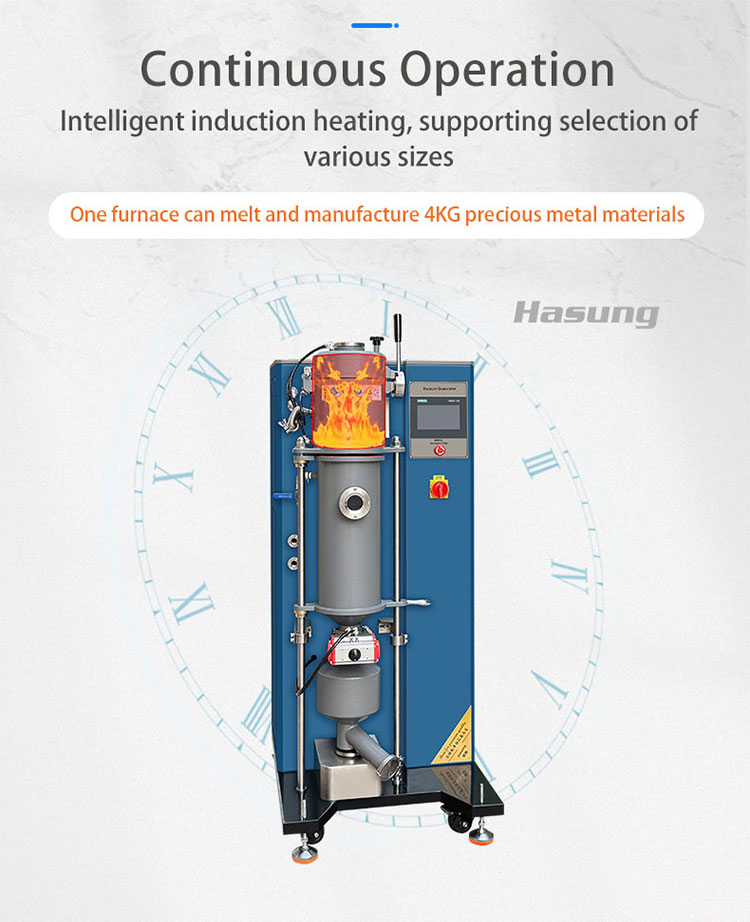

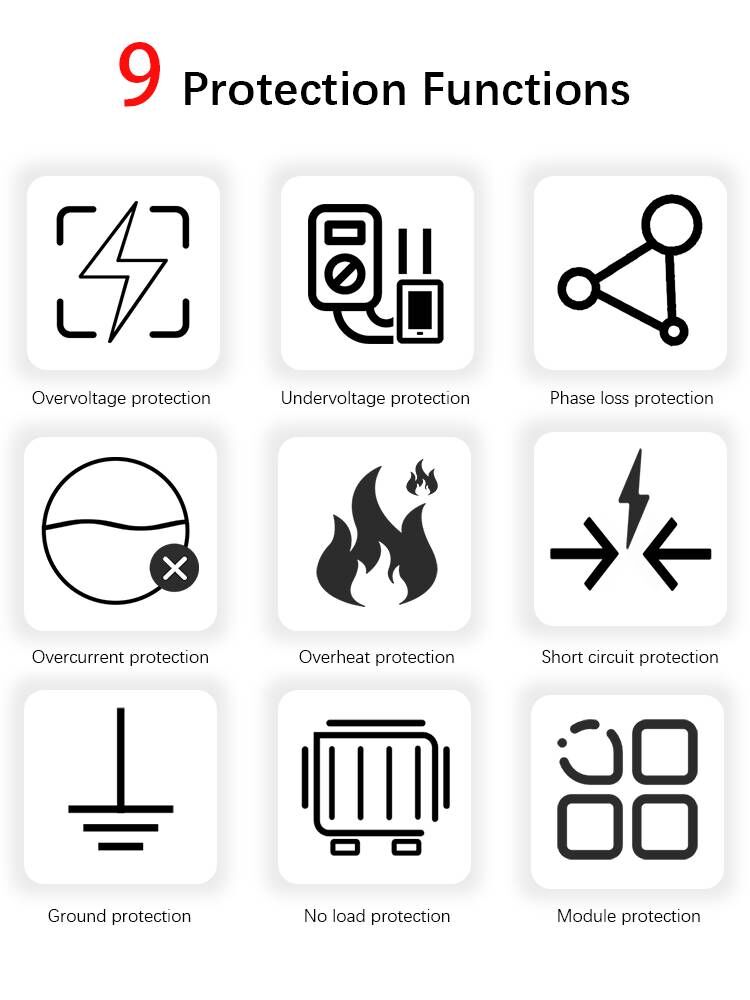

The vacuum gold granulating system excels in precision and efficiency, offering unparalleled performance in the gold and silver granulating process. With features like high-level vacuum capabilities, a user-friendly one-key operation, and advanced temperature accuracy of ±1°C, it delivers consistent granulation results for various precious metals, including copper and K gold. Built with durable materials and utilizing top-tier components, this system not only ensures exceptional reliability but also meets the demands of professional-grade environments for metal casting and smelting.

Company profile

**Company Profile:**

At our forefront, we specialize in cutting-edge equipment for the precious metals sector, proudly presenting the Vacuum Gold Granulating System. Our commitment to high-quality manufacturing ensures that every unit is crafted with precision and reliability, catering specifically to the needs of jewelers and gold refiners. With years of industry experience, we prioritize innovation, efficiency, and sustainability in our solutions. Our Vacuum Gold Granulating System not only enhances production capabilities but also elevates the purity and quality of gold. Trust us to deliver exceptional performance, empowering your business with the tools needed to thrive in a competitive market.

Enterprise core strength

**Company Profile**

At [Your Company Name], we specialize in cutting-edge solutions for the precious metals industry. Our Vacuum Gold Granulating System exemplifies our commitment to quality, innovation, and efficiency. With precision engineering and advanced technology, our equipment ensures optimal granulation of precious metals, maximizing yield and purity. We pride ourselves on our dedication to sustainability and customer satisfaction, providing tailored solutions backed by exceptional support and expertise. Trust [Your Company Name] to deliver high-quality machinery that enhances your operations, enabling you to achieve greater profitability and reliability in the competitive market of precious metals. Elevate your business with our industry-leading systems.

Product Description

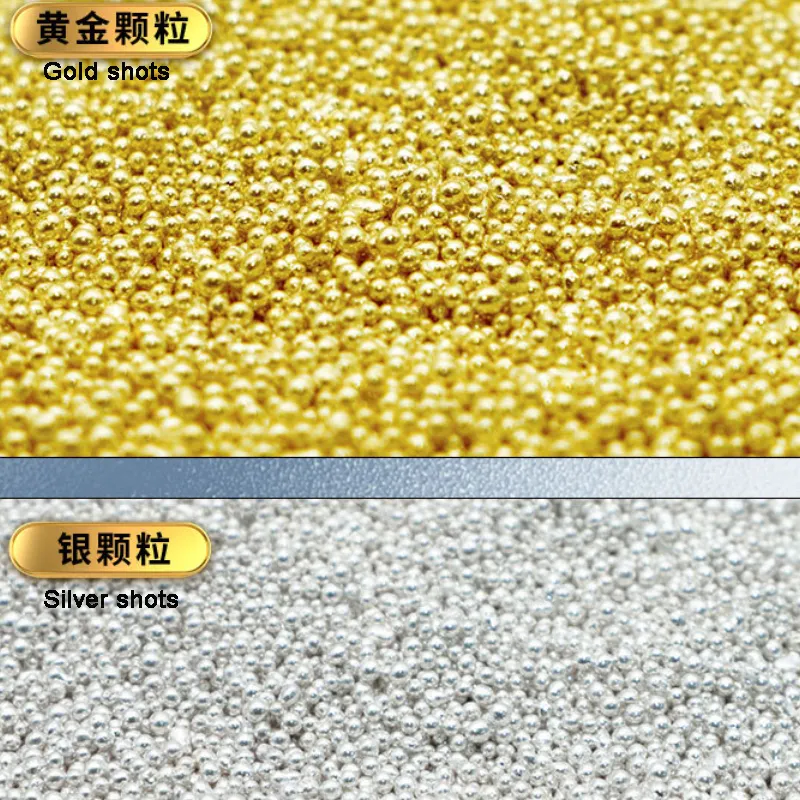

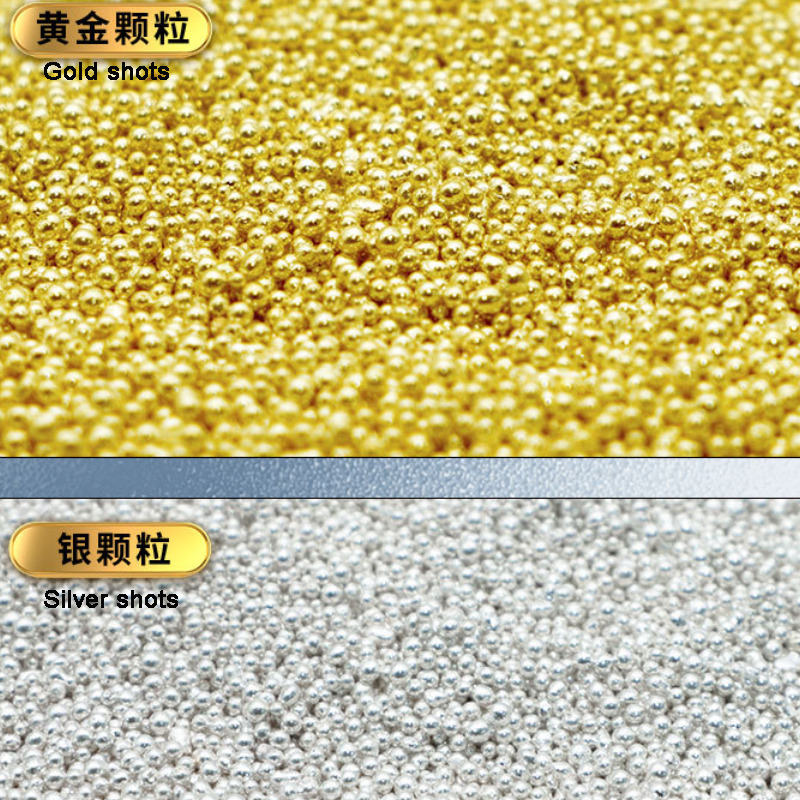

Gold Silver Granulating Process:

Technical Specification:

Model No. | HS-GR4 | HS-GR5 | HS-GR6 | HS-GR8 |

Voltage | 220V, 50/60Hz / 380V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

Power Supply | 0-15KW | 0-15KW | 0-15KW | 0-15KW |

Max Temp | 1500°C | |||

Casting Time | 1-2 min. | 3-5 min. | 2-5 min. | 3-6 min. |

Shielding Gas | Argon / Nitrogen | |||

Temp Accuracy | ±1°C | |||

Capacity | 4kg (Gold) | 5kg (Gold) | 6kg (Gold) | 8kg (Gold) |

Application | Gold, K gold, silver, copper and other alloys | |||

Vacuum | High level vacuum pump | |||

Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |||

Control system | Taiwan Weinview/Siemens PLC+Human-machine interface intelligent control system (optional) | |||

Cooling type | Water chiller(sold separately) or Running water | |||

Dimensions | 880x680x1580mm | 880x680x1580mm | 880x680x1580mm | 880x680x1580mm |

Weight | approx. 180kg | approx. 180kg | approx. 200kg | approx. 250kg |

FAQ

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and casting equipment, especially for high tech vacuum and high vacuum casting machines. Welcome to visit our factory in Shenzhen, China.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115