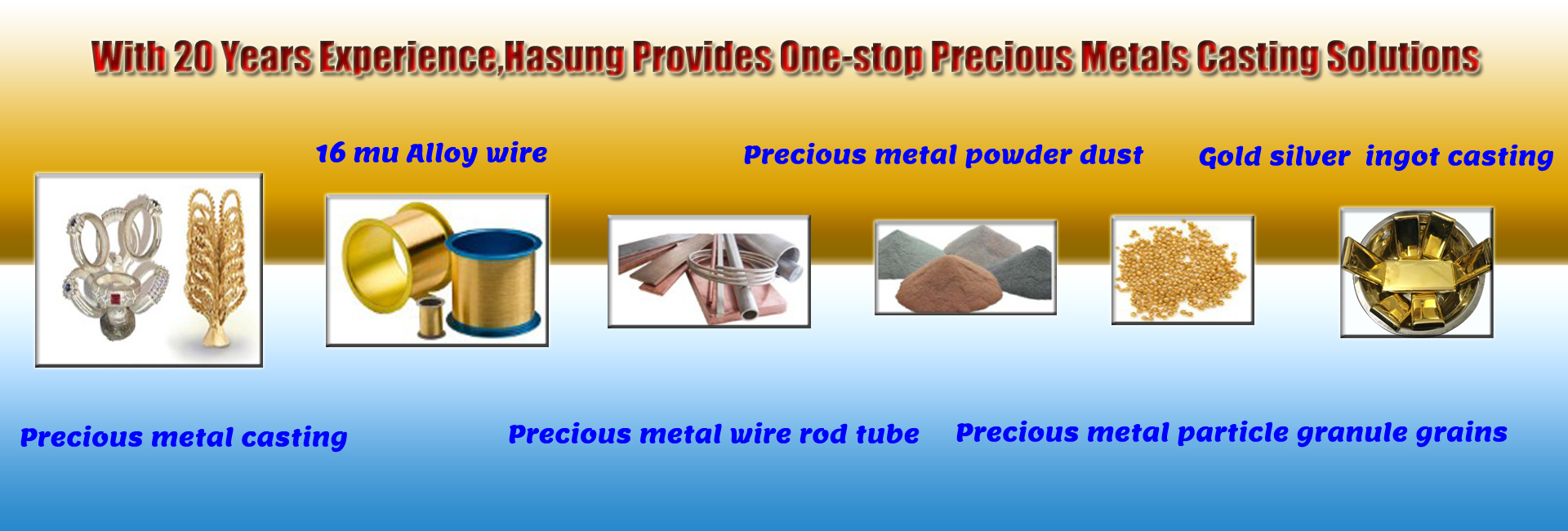

Metals continous wire drawing gold strip making machine for continous casting machine Continuous Casting Equipment

Metals continous wire drawing gold strip making machine for continous casting machine has obtained unanimous favorable comments from market.The quality assurance of it can be achieved with certification.Moreover,to take care of different needs, product customization is provided.

To keep up with the industry development, all employees of Shenzhen Hasung Precious Metals Equipment Co., Ltd have been doing their utmost to develop new products for days. High-end technologies helps us ensure Metals continous wire drawing gold strip making machine for continous casting machine quality, improve manufacturing efficiency, and reduce manpower input. It has extensive uses in the field(s) of Metal Casting Machinery. Compared with the traditional ones, it better meets the market demands.

| Place of Origin: | Guangdong, China | Condition: | New |

| Machine Type: | Casting machine | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2020 |

| Warranty of core components: | 2 years | Core Components: | PLC, Engine, Pressure vessel, Pump |

| Brand Name: | HASUNG | Voltage: | 220V 380V |

| Power: | 5KW 8KW | Dimension(L*W*H): | 680x880x1530mm |

| Warranty: | 2 years | Key Selling Points: | main components are original from japan and germany |

| Showroom Location: | None | Applicable Industries: | Manufacturing Plant, Home Use, Energy & Mining, Jewelry continuous casting machine |

| Weight (KG): | 150 | Application: | Gold, karat gold,silver and copper |

| Protective gas: | Nitrogen or Argon | Cooling: | Water chiller or tap water |

| Melting time: | 3 mins | Maximum Pressure: | 10-120Kpa adjustment |

| Metal capacity: | 1 kg | Max temperature: | 1500℃ |

| Operation method: | One-key operation to complete the entire process | control system: | Mitsubishi PLC |

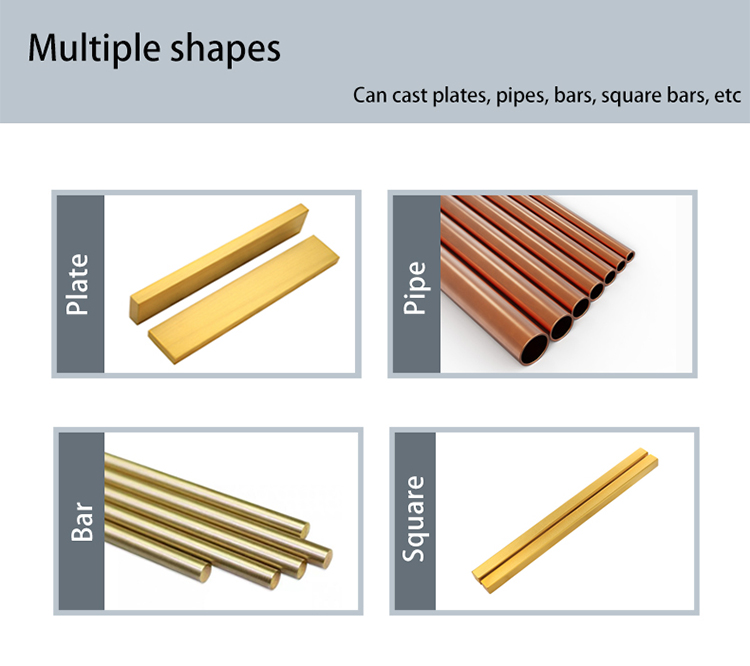

| Product shape: | strip, square, tube, can be customized |

Metals continous wire drawing tube forming machine for continous casting machine

Descriptions:

The design of this equipment system is based on the actual needs of the project and process, using modern high-tech technology.

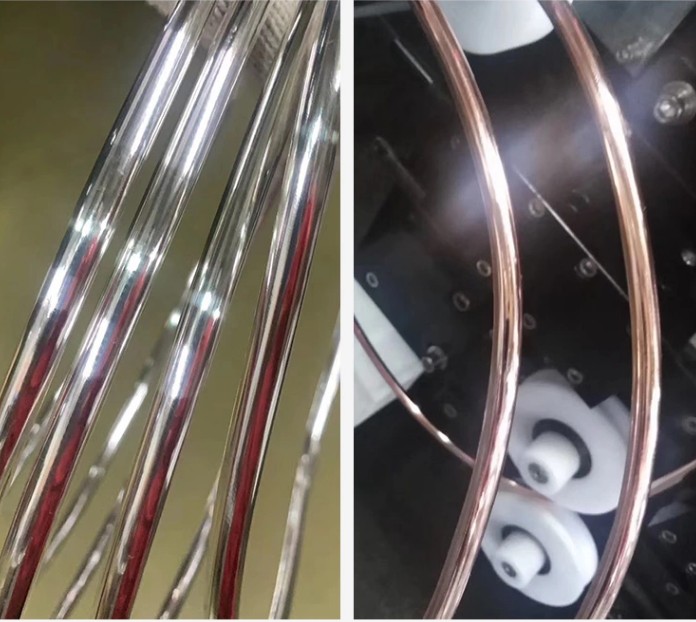

1. Using German high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

2. The closed type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Using a closed + vacuum/inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved.

4. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

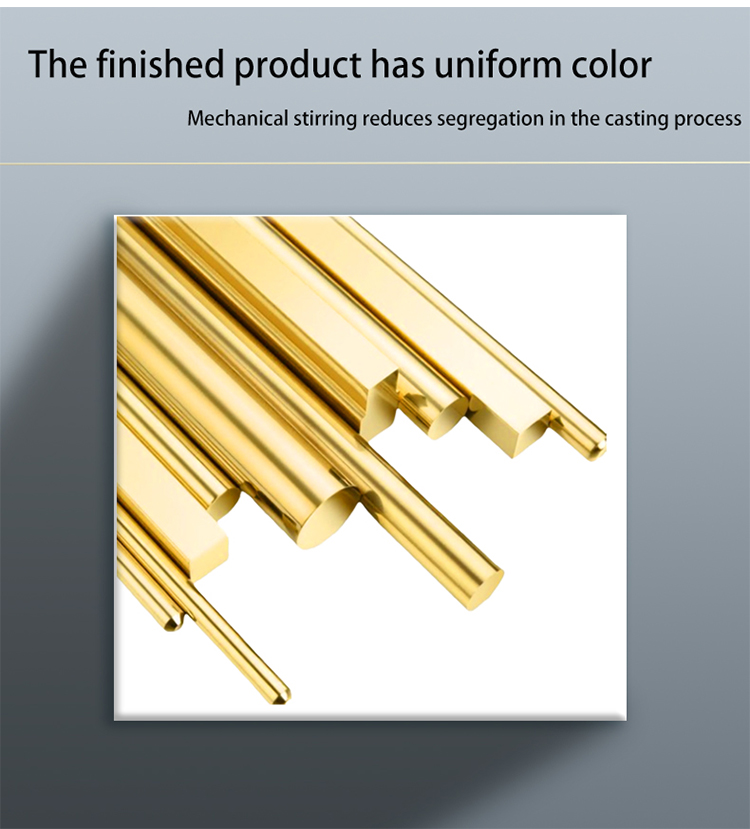

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. Using PID temperature control system, the temperature is more accurate (±1°C).

The HS-VCC1 vacuum pressurized casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of gold, silver, copper and other alloys.

9. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other well-known brand components at home and abroad.

10. Melting, electromagnetic stirring, and refrigeration in a closed + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

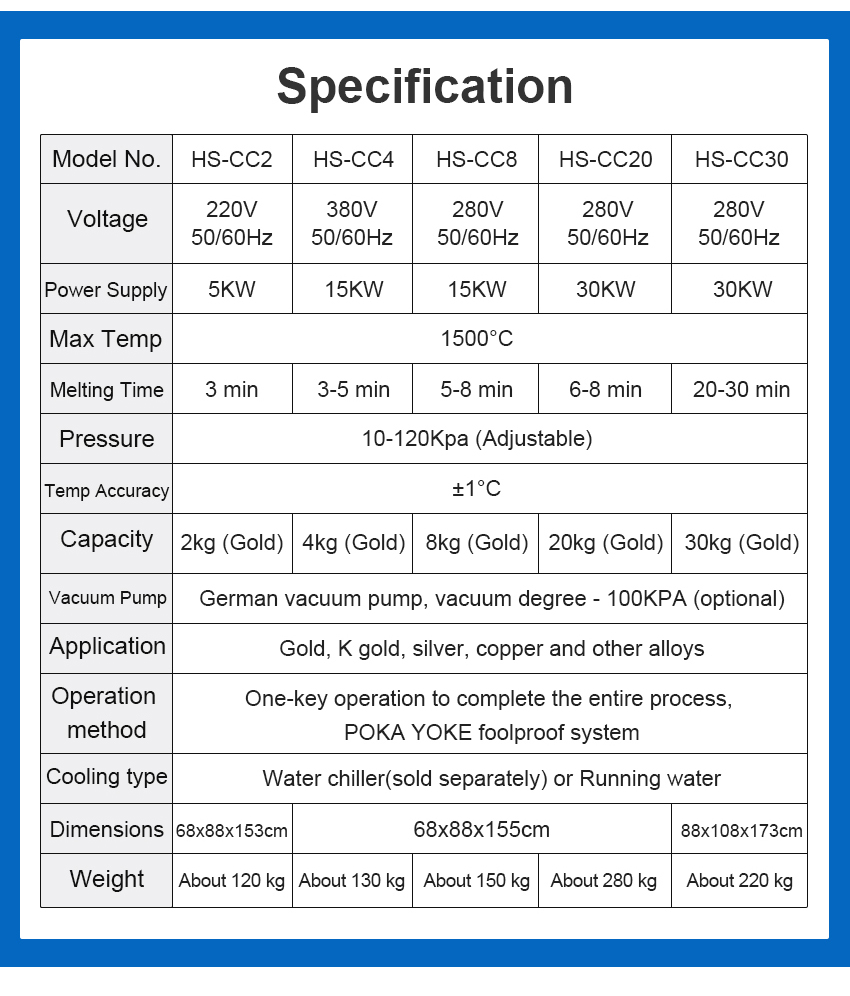

Specification

Power Supply | 220V 50/60Hz, single phase; 380V, 3 phases |

Power Input | 5KW/8KW/15KW |

Max Temp | 1500°C |

Melting speed | 3-5 minutes |

Casting shapes | strips, round rods, square, hexagon, pipes, etc. |

1kg 2KG 3KG 4KG 5KG 6KG 8KG (18K gold) | |

Suitable for | K-Gold,Gold, silver, copper |

Maximum flasks diameter | can be customized |

Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system |

control system | Mitsubishi PLC+Human-machine interface intelligent control system (optional) |

Blanketing with inert gas | Nitrogen/argon selection |

Temperature accuracy | ±1℃ |

| Product shape | strip, square, tube, can be customizedstrip |

Cooling type: water | chiller or Running water |

Vacuum pump | Original German Vaccum pump -98Kpa |

Dimensions | 680x880x1530mm |

Weight | 155kg |

,

Shenzhen Hasung Precious Metals Equipment Co., Ltd is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry. Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc. Our mission is to build the most innovative heating and casting equipment for precious metal manufacturing and gold jewellery industry, providing customers with the highest reliability in your daily operations and the best quality. We are acknowledged in the industry as a technology leader. What we're deserved to be proud is our vacuum and high vacuum technology is the best in China. Our equipment, manufactured in China, is made of highest-quality components, apply worldwide famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc.

Hasung has proudly served the precious metal casting & forming industry with vacuum pressure casting equipment, continuous casting machine, high vacuum continuous casting equipment, vacuum granulating equipment, induction melting furnaces, gold silver bullion vacuum casting machine, metal powder atomizing equipment, etc.

Our R & D department is always working on developing casting and melting technologies to suit our ever changing industry for the New Materials industry, Aerospace, Gold Mining, Metal Minting Industry, Research laboratories, Rapid Prototyping, Jewellery, and Artistic Sculpture. We do provide precious metals solutions for customers. We uphold the principle of "integrity, quality,cooperation, win-win" business philosophy,committed to creating first-class products and services. We always believe that technology changes the future.

We specialize in designing and developing custom finishing solutions. We strive to make the finishing process faster and more economical. Welcome to visit us.

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines. Welcome to visit our factory in Shenzhen, China.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115