Best Induction Jewelry Vacuum Pressure Casting Machine with Vibration System Company - Hasung

Hasung T2 Induction Jewelry Vacuum Pressure Casting Machine compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market. Hasung summarizes the defects of past products, and continuously improves them. The specifications of Induction Jewelry Vacuum Pressure Casting Machine with auto System can be customized according to your needs.

After multiple tests, it proves that utilizing technology contributes to high-efficiency manufacturing and ensuring the stability of High Quality Jewelry Making Machine Vacuum Casting Machine. It has widespread uses in the application field(s) of Jewelry Tools & Equipment and is totally worth the investment.

Model No.: HS-T2

The Newest Technology.

The First-Class Level Quality and Technology for Precious Metals Equipment Manufacturer in China.

Product Data Sheet

| Model No. | HS-T2 | HS-T2 |

| Voltage | 220V, 50/60Hz 1 Ph / 380V, 50/60Hz 3 Ph | 220V, 50/60Hz 1 Ph / 380V, 50/60Hz 3 Ph |

| Power | 8KW | 10KW |

| Max. temp. | (K-Type): 1200ºC; (R-Type): 1500ºC | |

| Melting speed | 1-2 min. | 2-3 min. |

| Casting pressure | 0.1Mpa - 0.3Mpa, 100 Kpa - 300 Kpa, 1 Bar - 3 Bar (adjustable) | |

| Max. Casting Amount | 24K: 1.0Kg, 18K: 0.78Kg, 14K: 0.75Kg, 925Ag: 0.5Kg | 24K: 2.0Kg, 18K: 1.55Kg, 14K: 1.5Kg, 925Ag: 1.0Kg |

| Crucible Volume | 121CC | 242CC |

| Max. cylinder size | 5"x9" | 5"x9" |

| Application metals | Gold, K gold, Silver, Copper, alloy | |

| Vacuum pressure setting | Available | |

| Argon pressure setting | Available | |

| Temperature setting | Available | |

| Pouring time setting | Available | |

| Pressure time setting | Available | |

| Pressure hold time setting | Available | |

| Vacuum time setting | Available | |

| Program for flask with flange | Available | |

| Program for flask without flange | Available | |

| Overheat protection | Yes | |

| Flask lifting height adjustable | Available | |

| Different flask diameter | Available, using different flanges | |

| Operation method | One-key operation to complete the entire process | |

| Control system | Taiwan Weinview PLC touch panel | |

| Operation mode | Automatic mode / Manual mode (both) | |

| Inert gas | Nitrogen/argon (optional) | |

| Cooling type | Running water / Water chiller (Sold separately) | |

| Vacuum pump | High performance vacuum pump (included) | |

| Dimensions | 800*600*1200mm | |

| Weight | approx. 250kg | |

| Packing weight | approx. 320kg. (vacuum pump approx. 45kg) | |

| Packing size | 830*790*1390mm (casting machine) 620*410*430mm (vacuum pump) | |

Product Description

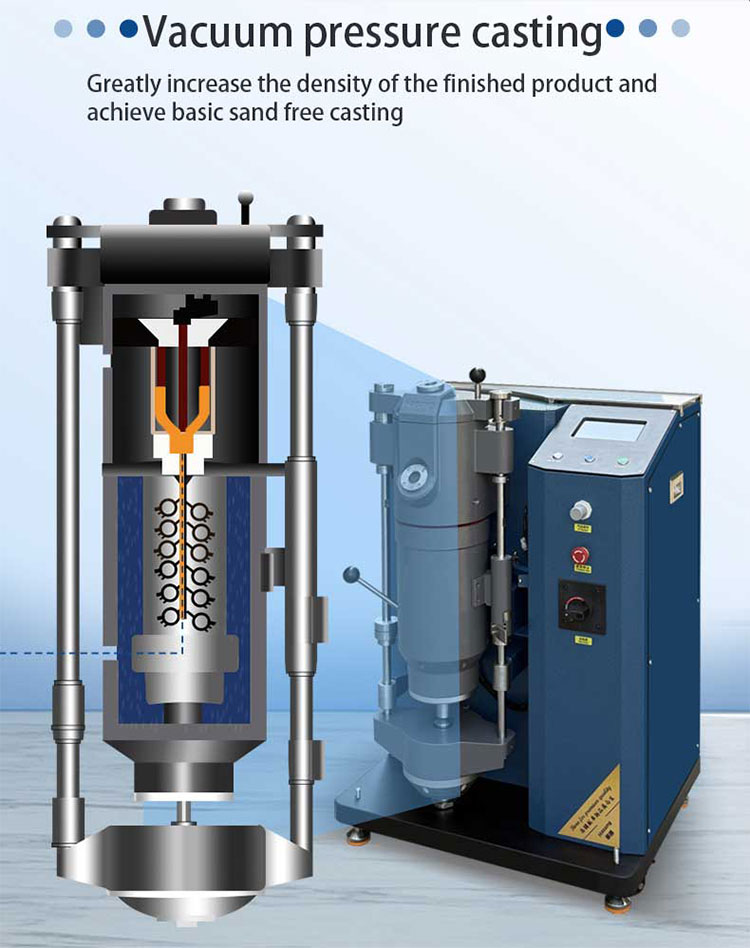

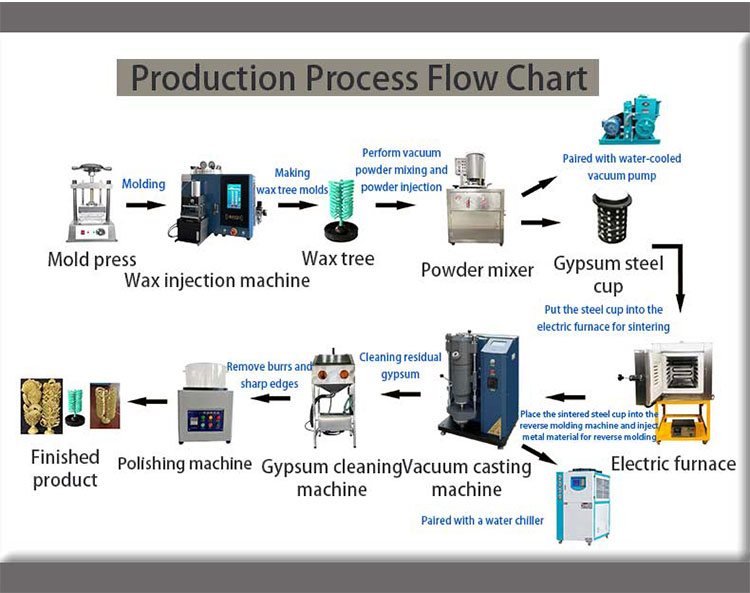

Hasung T2 series induction vacuum casting machine is the most innovative in the latest generation of pressure vacuum casting machine in the world market. They use low-frequency generators, and the power control is proportional and is managed entirely by a computer. The operator simply puts the metal into the crucible, places the cylinder and presses the button! The "T2" series model comes with a 7-inch color touch screen. Throughout the merger process, the operation is gradual.

Automatic process:

When press button of “Auto”, vacuum, inert gas, heating, strong magnetic mixing, vacuum, casting, , vacuum with pressure, cooling, all processes done by one key mode.

Regardless of the type and quantity of gold, silver, and alloy, the frequency and power are modulated. Once the molten metal reaches the casting temperature, the computer system adjusts the heating and emits a low-frequency pulses to sense the stirring alloy. The casting starts automatically, followed by a strong pressurization of the metal with an inert gas.

T2 series casting machine is one of the most innovative in the latest generation of pressure vacuum casting machine in the world market.

They use low-frequency generators, and the power control is proportional and is managed entirely by a computer.

The operator simply puts the metal into the crucible, places the cylinder and presses the button! The

"T2" series model comes with a 7-inch color touch screen.

Throughout the merger process, the operation is gradual.

Regardless of the type and quantity of gold, silver, and alloy, the frequency and power are modulated.

Once the molten metal reaches the casting temperature, the computer system adjusts the heating and emits a low-frequency pulses to sense the stirring alloy.

When all set parameters are reached, the casting starts automatically, followed by a strong pressurization of the metal with vacuum.

![Best Induction Jewelry Vacuum Pressure Casting Machine with Vibration System Company - Hasung 22]() Company Advantages

Company Advantages

Frequently Asked Questions about wire bonding equipment

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115

Company Advantages

Company Advantages